Light emitting diode drive system and display device using light emitting diode drive system

A technology of light-emitting diodes and driving systems, which can be used in three-dimensional systems, static indicators, instruments, etc., and can solve the problems of difficulty in selecting components of LED driving systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

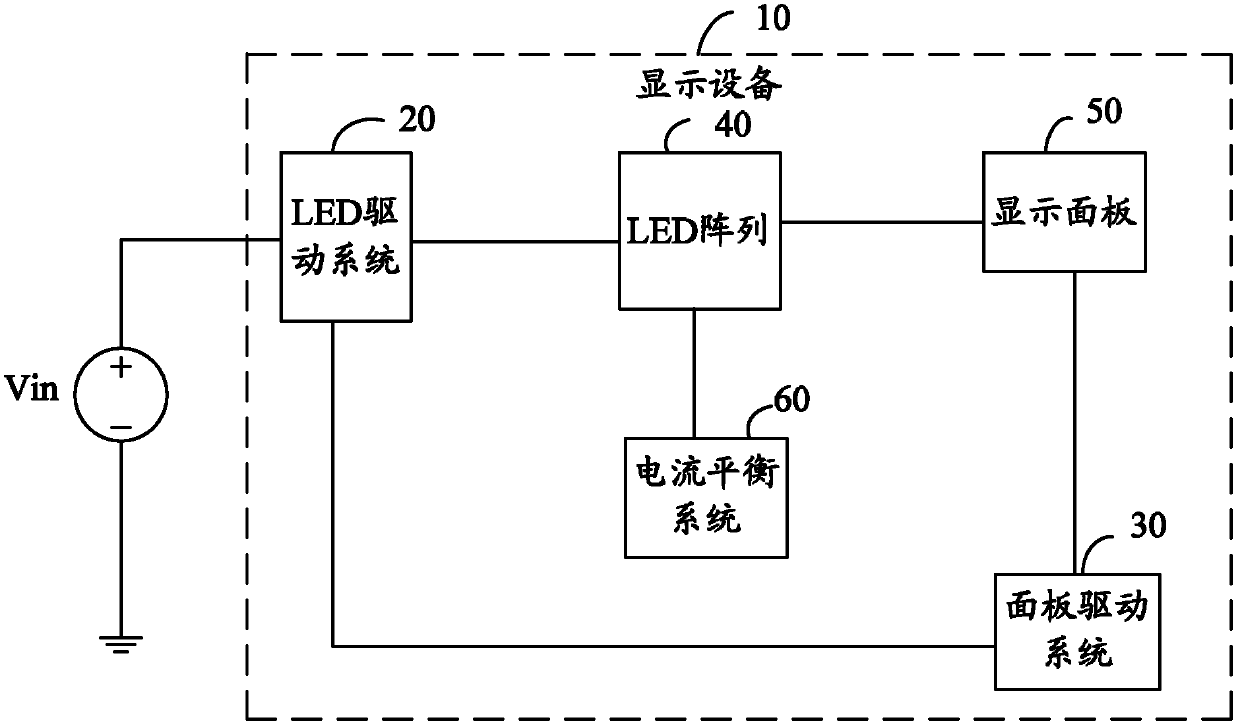

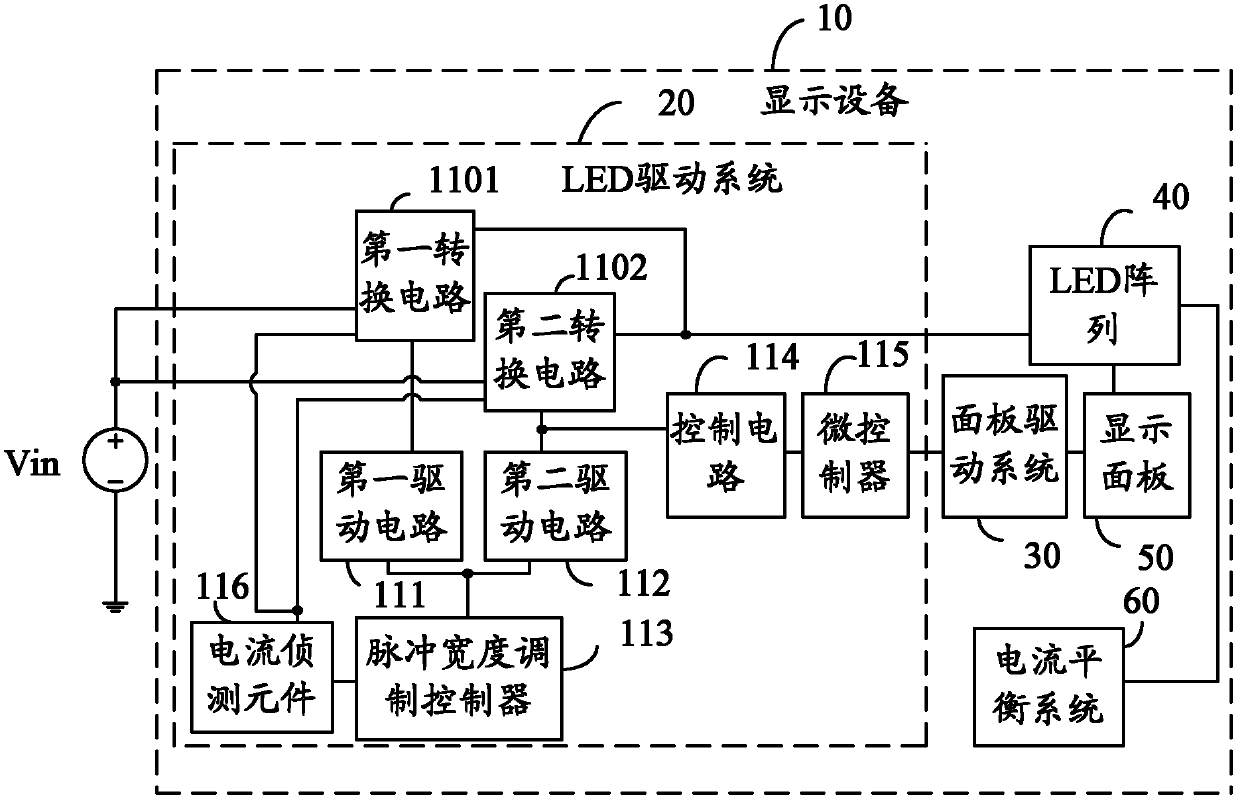

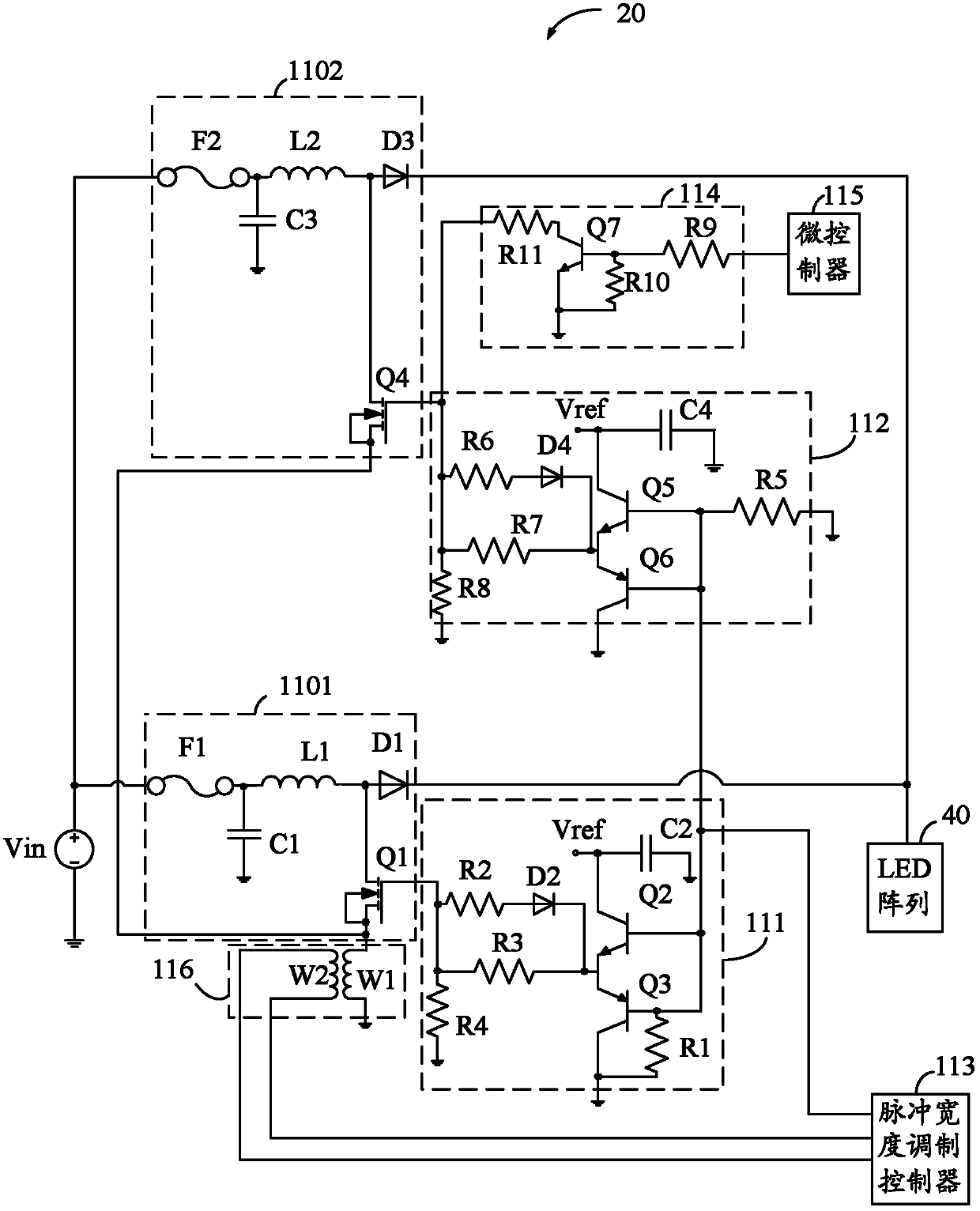

[0053] figure 1 It is a block diagram of the display device 10 in an embodiment of the present invention. The display device 10 includes an LED driving system 20 , a panel driving system 30 , a light emitting diode (Light Emitting Diode, LED) array 40 , a display panel 50 and a current balance system 60 . In this embodiment, the LED array 40 includes a plurality of LED strings connected in parallel, and each LED string is composed of a plurality of LEDs connected in series in the forward direction. The anode of the LED string refers to the anode of the first LED in the LED string, and the cathode of the LED array Refers to the cathode of the last LED in the LED string. The display device 10 has two display modes of two dimensions (2 dimensions, 2D) and three dimensions (3 dimensions, 3D), and for the LED driving system 20, the 2D mode and the 3D mode are two different load characteristics. The display panel 50 is used for 2D or 3D display. The panel drive system 30 is used to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap