Pipeline gas leakage detecting device

A gas leak detection and detection device technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of high labor and time consumption, low instrument detection efficiency, inconvenient movement, etc., to save time and manpower, easy to apply and promote, to provide the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

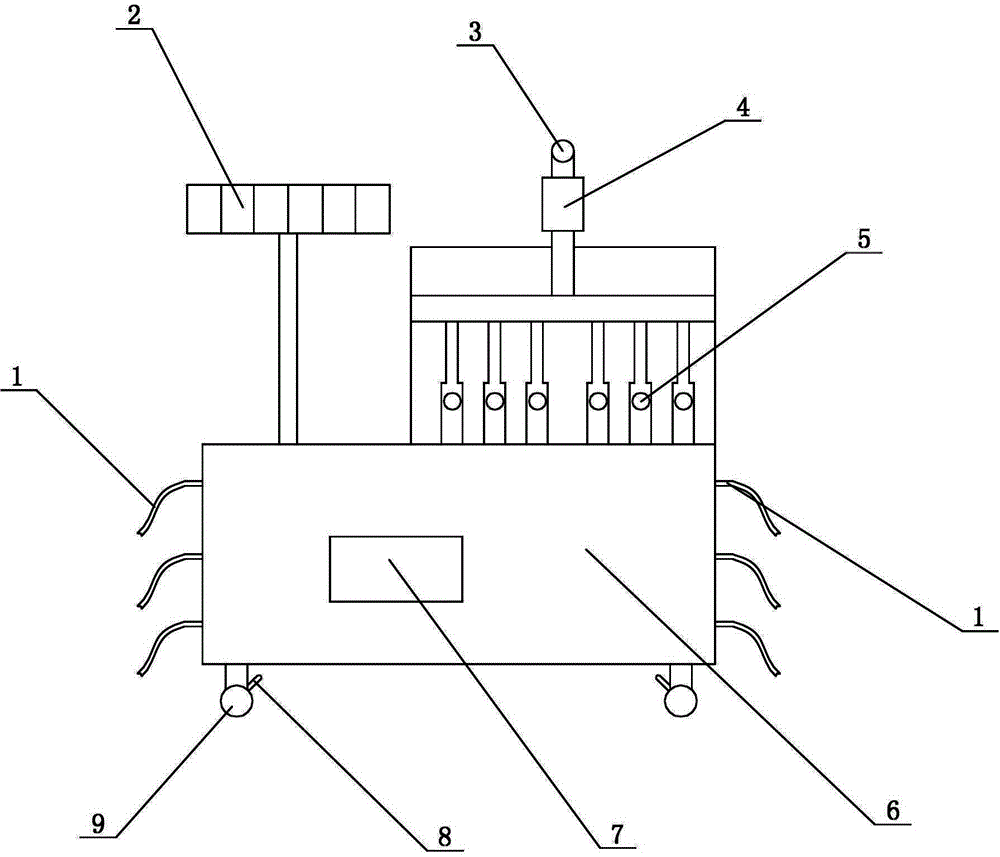

[0022] see figure 1 , a pipeline gas leakage detection device, including a casing 6, a controller 7 is arranged inside the casing 6, and the controller is electrically connected to a pressure detection device and an indicating device. The upper end of the housing 6 is provided with a bracket, and several pressure detection devices are installed in the bracket, and all the pressure detection devices are connected with an indicating device. The pressure detection device is connected with a pressure transmitter and a temperature transmitter arranged at the position to be detected.

[0023] In this embodiment, the pressure detection device includes a connecting pipe, and the connecting pipe communicates with the pressure gauge 5 provided in the bracket. The pressure gauge 5 corresponds to the connecting pipe one by one, and the pressure gauge 5 is electrically connected to the controller. Here, the pressure gauge is generally set inside the connecting pipe and does not leak out.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap