Stainless branching screw

A technology of screw and wire separation, applied in the field of mechanical parts, can solve the problems of short service life and easy rust of screws, and achieve the effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

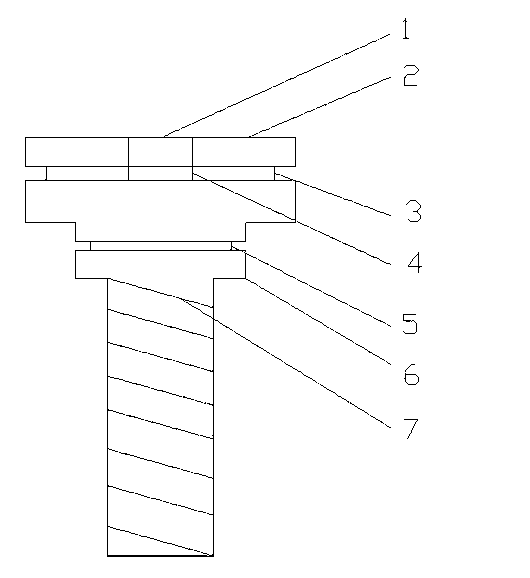

[0012] see figure 1 , a kind of anti-rust branching screw, comprising: a screw body 2, a first fixing groove 3, a second fixing groove 5, a screw rod 6, a thread 7 and a mounting hole 1, and the first fixing groove 3 is opened on the screw body 2, the second fixing groove 5 is opened at the rear end of the screw body 2, the screw rod 6 is integrally formed with the screw body 2 and is arranged on the top of the screw body 2, and the edge of the screw rod 6 is provided with threads 7. The tail end of the screw body 2 is provided with a mounting hole 1 .

[0013] In addition, the surface of the screw body 2, the thread 7 and the screw rod 6 are all s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap