Centering guidance system in strip rolling production line

A guiding system and production line technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve problems such as high cost, harsh environment, and inaccurate alignment, and achieve the effect of low cost, high quality, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention provides a centering and guiding mechanism of a strip rolling production line with compact structure, simple adjustment, fast and accurate operation, flexible and convenient use, and meeting the requirements of strip centering and guiding and correcting deviation. It is suitable for cold rolling, hot rolling main rolling line, slitting and horizontal shearing, stretching and straightening and other finishing lines, auxiliary lines, etc. In the production line, the mechanism can realize the centering and guiding of the strip and ensure that its center coincides with the production center line. For example, at the entrance and exit of the rolling mill, the strip is centered and guided to ensure that its center coincides with the rolling line and correct deviation.

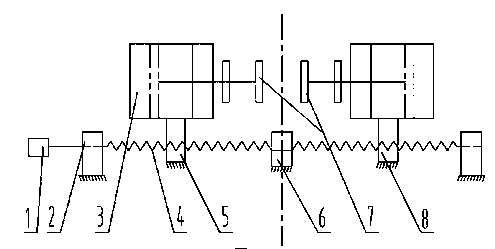

[0013] see figure 1 , the concrete structure of centering guide system of a kind of strip rolling production line that the present invention relates to is:

[0014] Including oil motor 1, bearing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap