Method using standard die to processing any circular arc

A standard mold and processing method technology, applied in the field of arc processing, can solve the problems of changing molds, high enterprise cost, long cycle, etc., and achieve the effect of simple process steps, broad application prospects and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

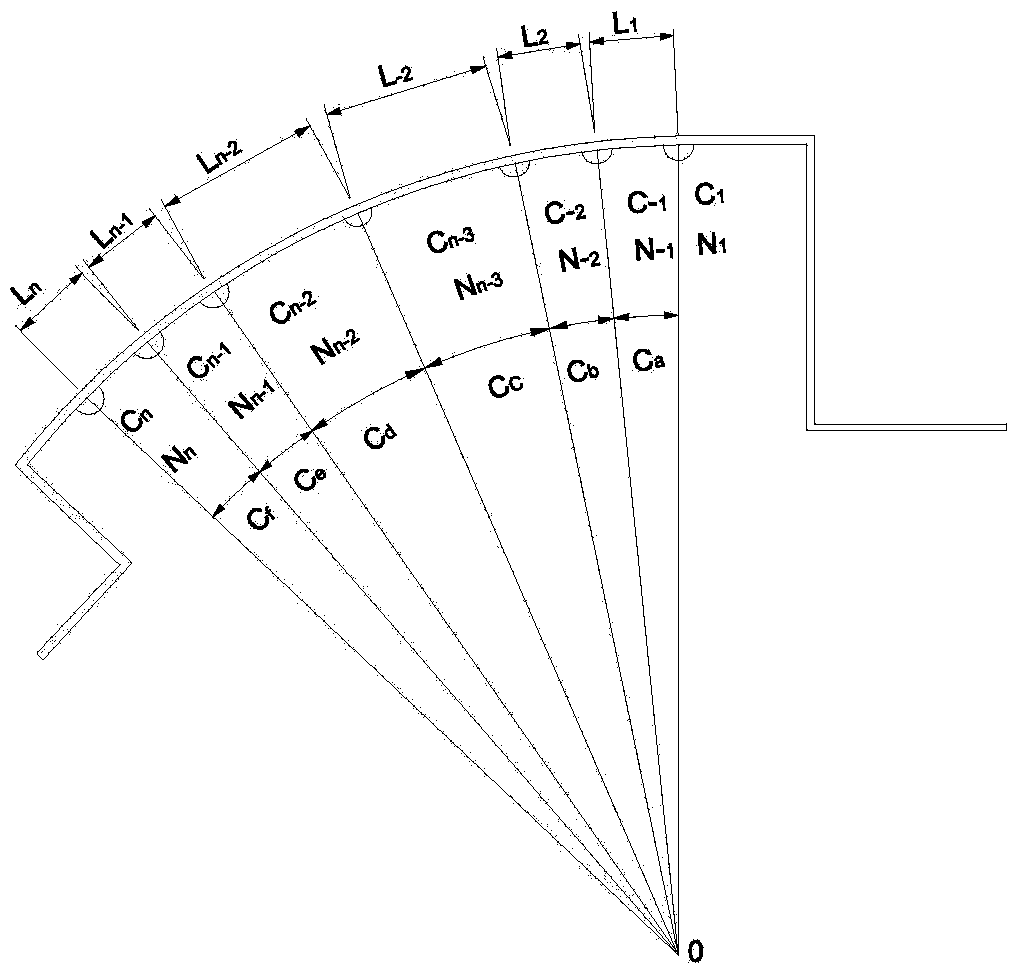

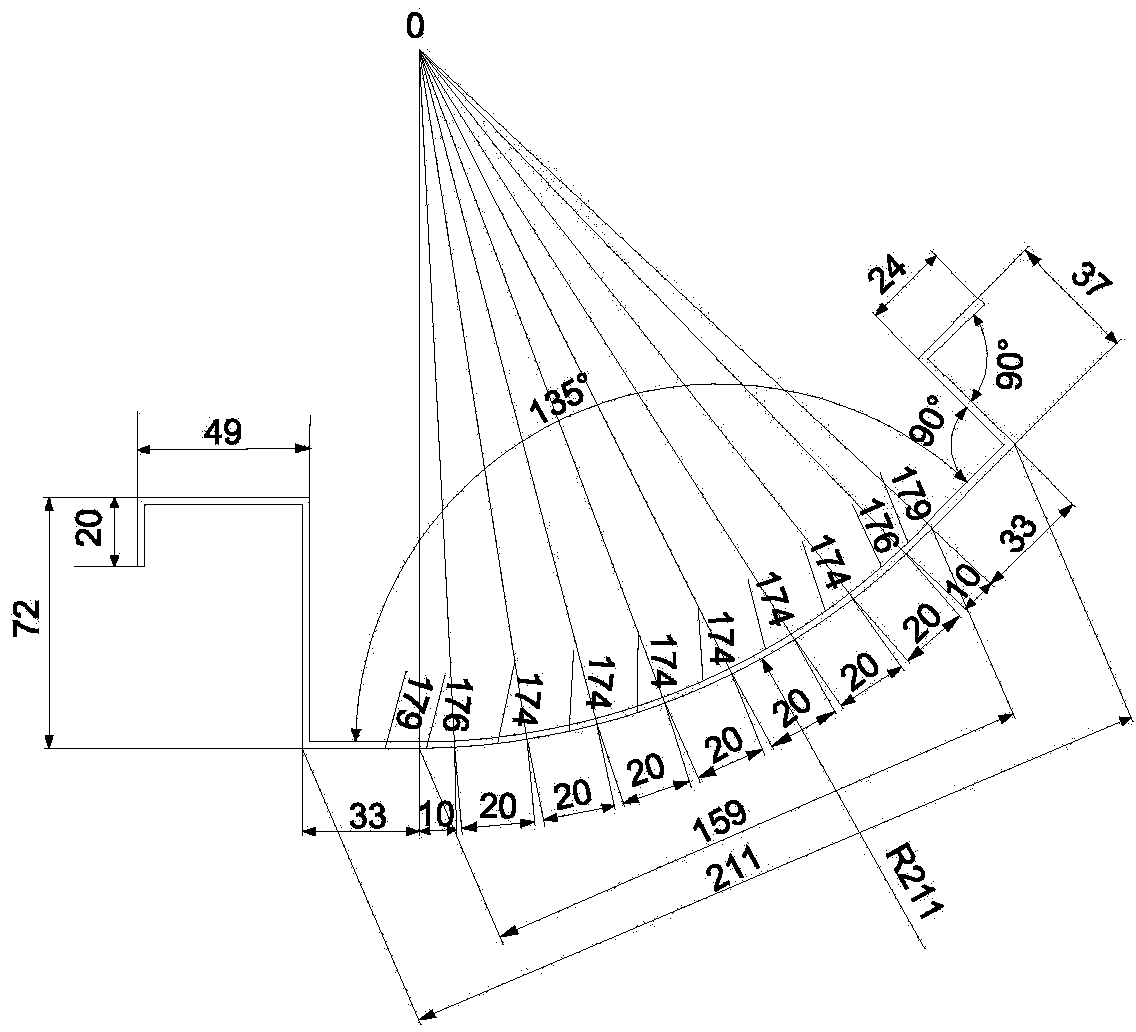

[0024] Embodiment 1 takes the circular arc of processing R200 as an example to illustrate as follows, as Figure 2A to Figure 4J As shown, the processing method is as follows:

[0025] Use a standard 2mm sheet metal and a bending die with a V-groove of 16;

[0026] Step a) Divide the arc of R200 into nine segments of 10+20+20+20+20+20+20+10, among which 10>0.5V, such as Figure 2A shown;

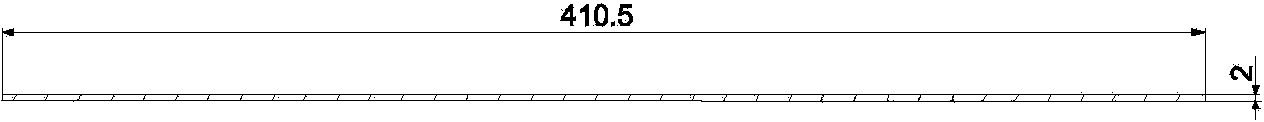

[0027] Step b) Calculate the flattened size of the part (mm): 20+49+72+33+(10+20+20+20+20+20+20+10)+33+37+24-3.5*0.5=410.5, Such as Figure 2B shown;

[0028] Step c, d) According to the process and technical requirements, the material is cut, and the standard bending mold with a V groove of 16 is operated according to the bending machine, and the accuracy of the rear gauge and the sliding accuracy of the slider are adjusted;

[0029] Step e) Complete the process forming according to the normal bending process procedure, such as Figure 2C shown;

[0030] Step e) further includes a preli

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap