Actual load measuring method of ultra-high-rise steel and concrete combination structure

A combined structure and concrete technology, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems of engineering application difficulty, complex analysis methods, etc., and achieve the effect of convenient operation, good application value, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

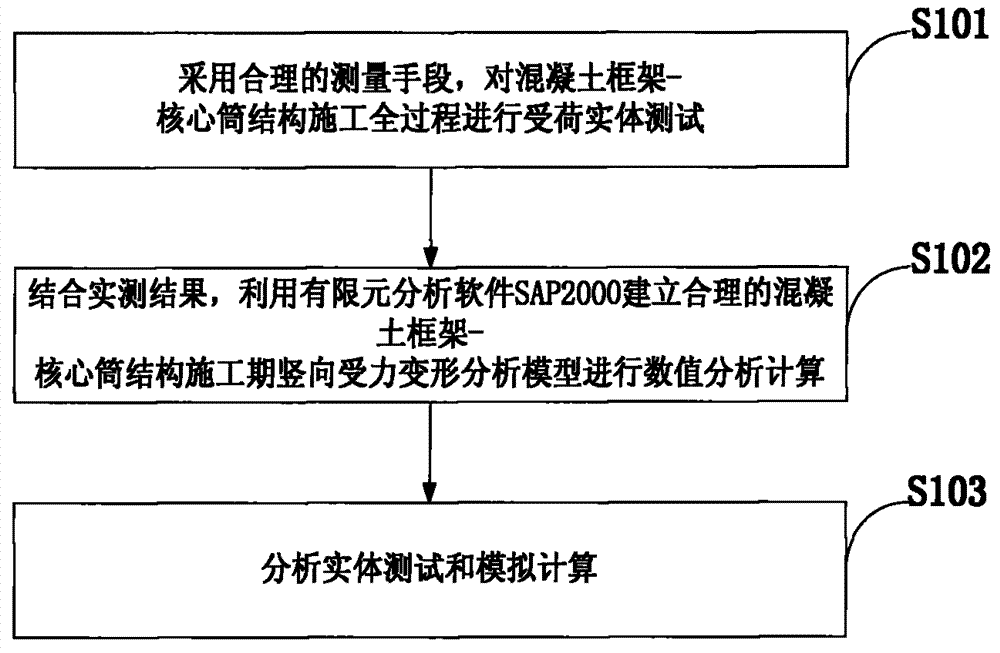

[0020] figure 1 The method for measuring the load of the super high-rise steel-concrete composite structure provided by the present invention is shown. For ease of illustration, only the parts relevant to the present invention are shown.

[0021] The actual load measurement method of the super high-rise steel-concrete composite structure of the present invention, the load measurement method of the super high-rise steel-concrete composite structure comprises the following steps:

[0022] By means of measurement, the load-bearing entity test is carried out on the whole construction process of the concrete frame-core tube struc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap