Damping spring vibration isolator with adjustable preload

A damping spring, preload technology, applied in the direction of spring/shock absorber, shock absorber, friction shock absorber, etc., can solve the problems of good vibration isolation effect and large compression deformation, achieve small vibration transmission, prevent isolation Vibration failure, the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

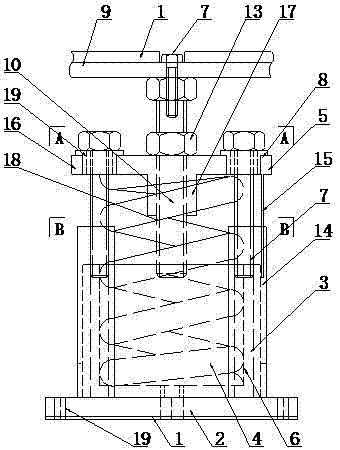

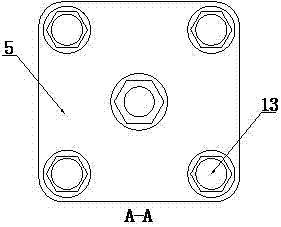

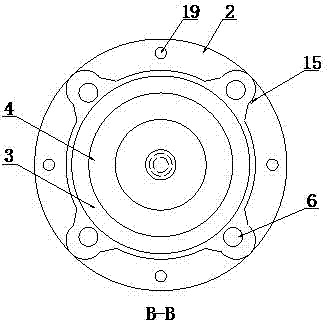

[0018] exist figure 1 , 2 , In the embodiment shown in 3, an adjustable preload damping spring vibration isolator is composed of a damping spring vibration isolator, an adjustable preload member, a height adjustment structure, and a preload indicating device. The damping spring vibration isolator is composed of rubber friction sound insulation pad (1), base (2), rubber damping sleeve (3), helical steel spring (4), and positioning plate (5); the adjustable preload member is composed of internal thread pipe (6), preloading screw (7), rubber tooth-shaped circular hole damping sleeve (8), and washer; the height adjustment structure is composed of upper cover plate (9), screw (10), circular bearing body (11), Fixed plate (12), level adjustment nut (13) is formed. The preload indicating device is composed of a marking scale (14) and a marking rod (15).

[0019] The base (2) of the damping spring vibration isolator and the internal threaded pipe (6) of the adjustable preload member a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap