Bone screw

A bone screw and screw technology, applied in the field of medical devices, can solve the problems of increasing the torque of the bone screw, increasing the torque of screwing in, increasing the difficulty of operation, etc., and achieve the effects of reducing the bearing torque, convenient processing and operation, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

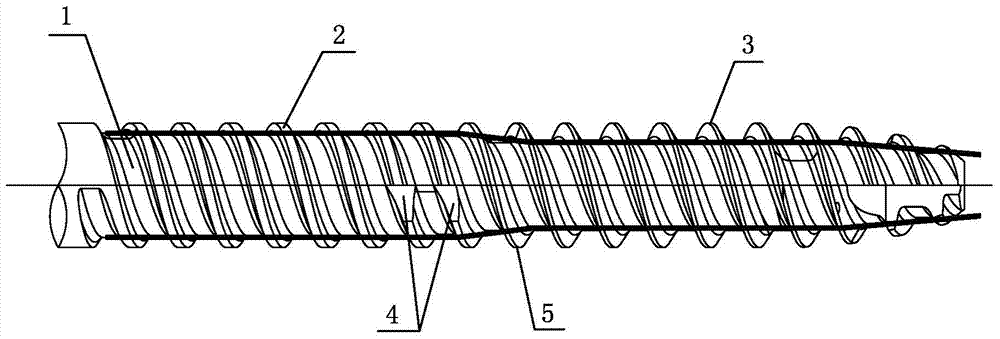

[0019] Examples, see figure 1 As shown, a bone screw of the present invention includes a screw shank 1, which is provided with a screw thread, and the screw thread includes an interconnected front thread and a rear thread, and the rear thread is a shallow thread 2 located in the cortical bone segment. , the front thread is the deep thread 3 located in the cancellous bone segment; the outer diameter of the shallow thread 2 and the deep thread 3 are the same, and the inner diameter of the shallow thread 2 is larger than the inner diameter of the deep thread 3, so that the diameter of the screw shank 1 where the shallow thread 2 is located It is larger than the diameter of the screw shank 1 where the deep thread 3 is located. The front end of the shallow thread 2 is provided with a self-tapping groove 4. Specifically, the radial dimension of the self-tapping groove 4 gradually increases along the direction from the front end of the shallow thread to its rear end, and the groove surf

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap