Butadiene styrene rubber wastewater treatment process

A technology of styrene-butadiene rubber and wastewater treatment, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as unsuitable styrene-butadiene rubber wastewater treatment, and achieve stable treatment effect , Simple equipment, simplified process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

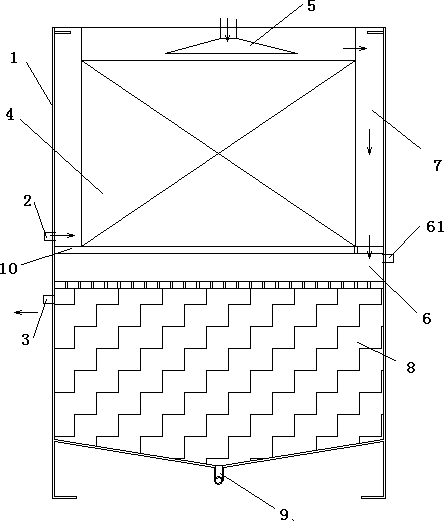

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

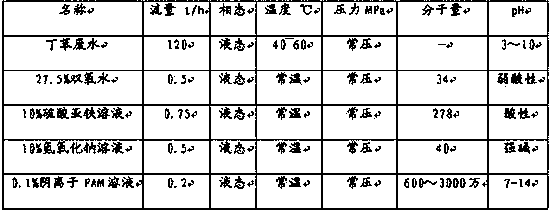

[0042] Such as figure 1 As shown, the integrated high-efficiency water treatment reactor includes a shell 1, a water inlet 2 and a water outlet 3 arranged on the wall of the shell 1; The nozzle 2 is arranged at the bottom of the coalescing packing area 4 . The water inlet 2 should adopt a liquid distributor structure. The housing 1 is provided with a coalescing packing area 4, a catalytic oxidation reagent inlet 5 arranged above the coalescing packing area 4, and a flocculation reaction chamber 6 arranged below the coalescing packing area 4; A waste water channel 7 surrounding the coalescing filler area 4 is arranged between them; an inclined tube settling tank 8 is arranged under the flocculation reaction chamber 6; a mud discharge port 9 is arranged at the bottom of the inclined tube settling tank 8; The flocculant inlet 61; the partition 10 is set between

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap