Lead-acid battery and manufacturing method thereof

A technology for lead-acid batteries and manufacturing methods, applied in the direction of lead-acid batteries, lead-acid battery construction, secondary batteries, etc., can solve problems such as limiting battery flexibility, and achieve the effect of high use flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

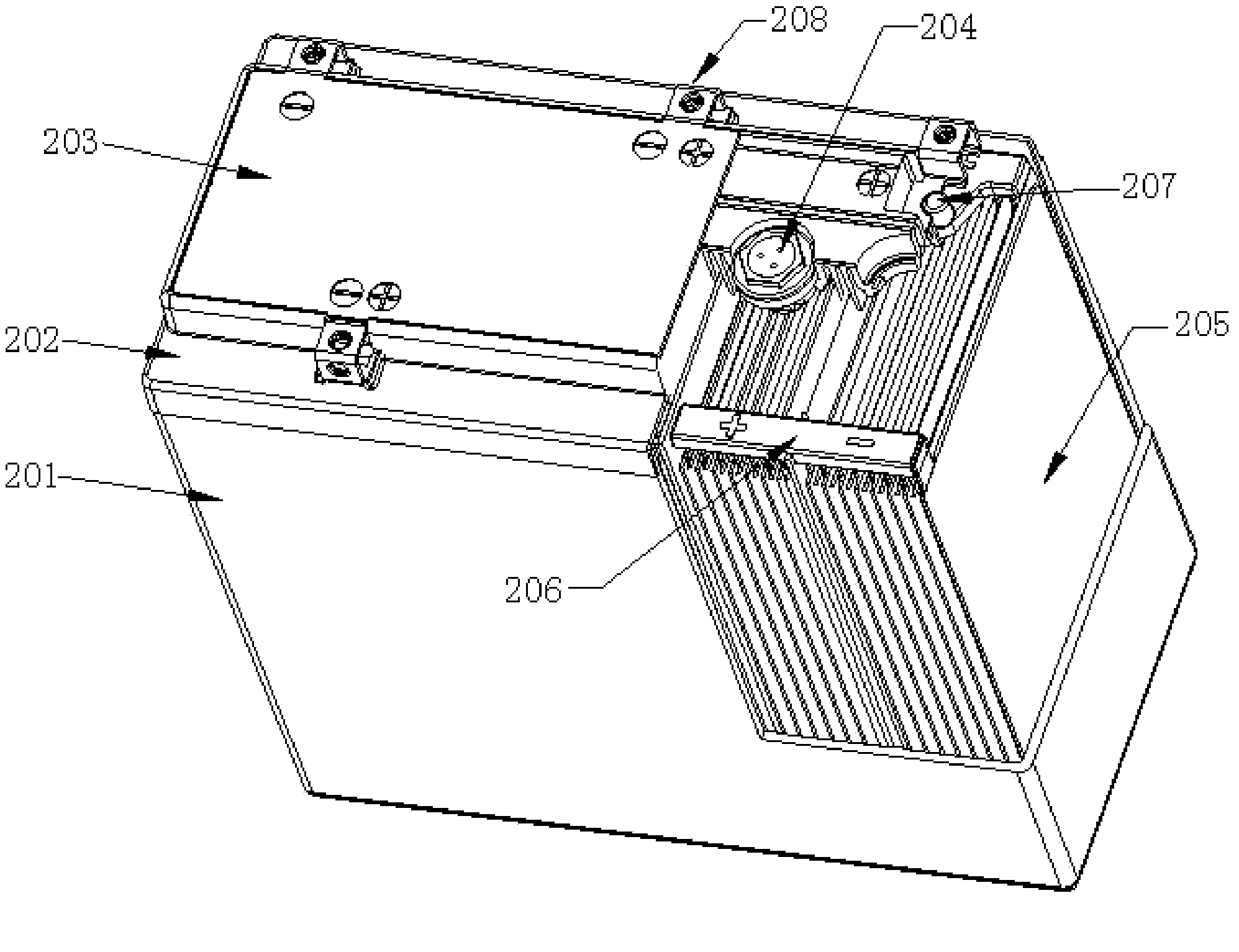

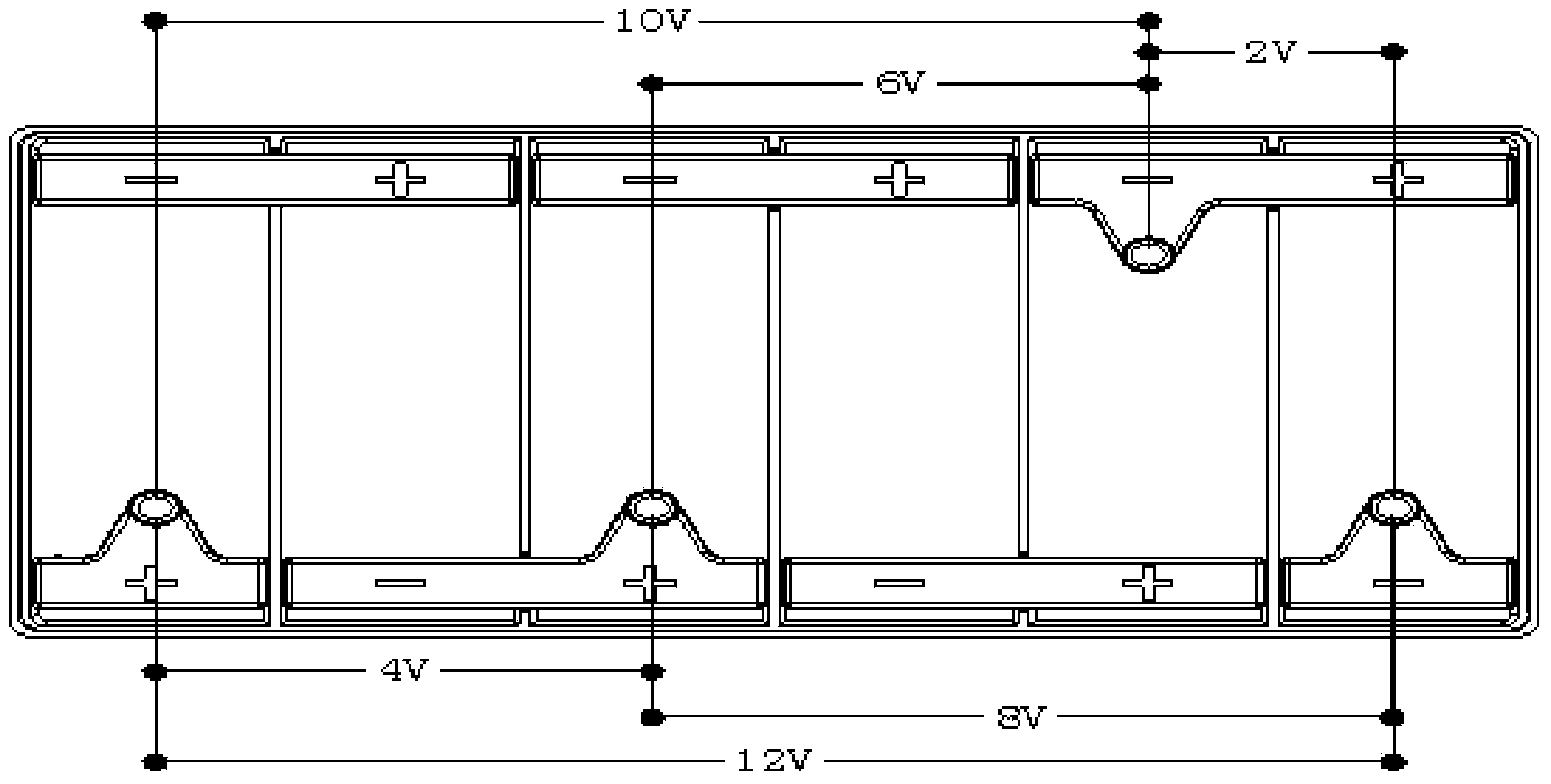

[0030] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

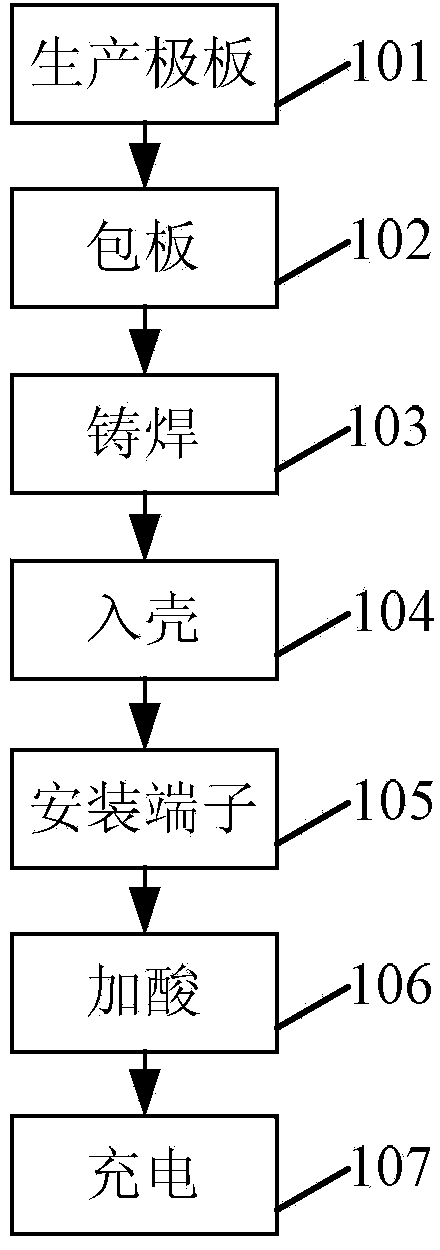

[0031] Please refer to figure 1 , the present embodiment provides a method for manufacturing a lead-acid battery, comprising:

[0032] Step 101: producing polar plates. The plates include positive plates and negative plates. Preferably, the lead-calcium-tin-aluminum alloy is used as the raw material, and the pole plate is produced by a stretching method. The positive and negative plates are made of lead-calcium-tin-aluminum alloy, which can improve the high-current discharge performance of the battery. Compared with the conventional gravity pouring method, the thickness of the pole plate can be effectively reduced by adopting the method of pulling the net to produce the pole plate. Further, rare metal elements are added to the lead-calcium-tin-aluminum alloy to enhance the corrosion resistance of the pole plate, so as to increa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap