Part quality defect detector and method for detection with same

A technology of quality defects and detectors, applied in the field of mechanical parts inspection, can solve the problems of high price and low measurement accuracy, and achieve the effects of low cost, high degree of automation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

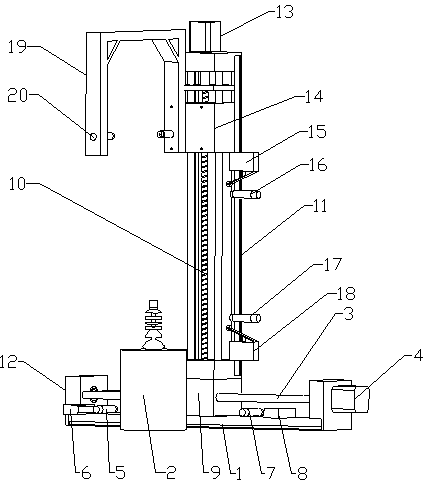

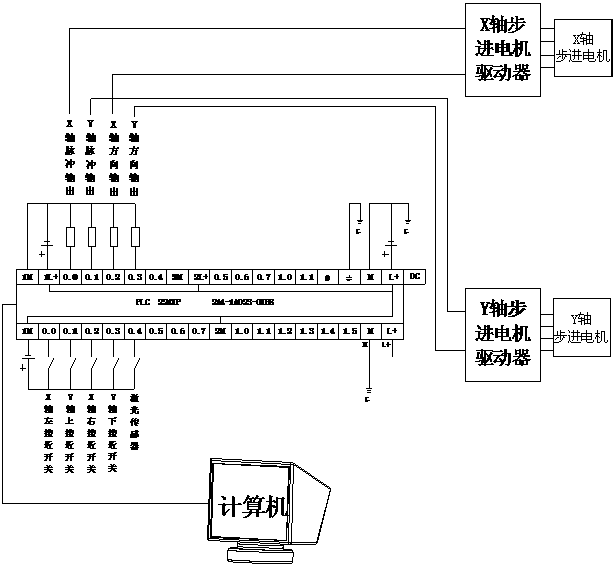

[0016] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, this kind of parts quality defect detector includes an X-axis slide rail 1, and one side of the X-axis slide rail 1 is connected with a part placement table 2, and an X-axis screw 3 is arranged on the X-axis slide rail 1, and the X-axis wire The two ends of the bar 3 are fixed on the X-axis slide rail 1 through the bearing housing 12, one end of the X-axis screw 3 is connected to the X-axis stepping motor 4, and the left end of the X-axis slide rail 1 is provided with the X-axis left approaching in turn from the inside to the outside. Switch 5 and X-axis left travel switch 6, the right end of X-axis slide rail 1 is provided with X-axis right proximity switch 7 and X-axis right travel switch 8 from inside to outside in sequence, X-axis screw 3 is covered with X-axis slider 9 , the X-axis slider 9 can move back and forth between the X-axis right proximity switch

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap