Integrated positioning pin hole structure

A combined positioning and positioning pin hole technology, applied in the direction of bolts, etc., can solve the problems of reducing the reliability of the machine, the positioning pin deviates from the correct installation position, and the axial movement range of the positioning pin is large, so as to improve the reliability of the machine and ensure the installation accuracy. , to avoid the effect of difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

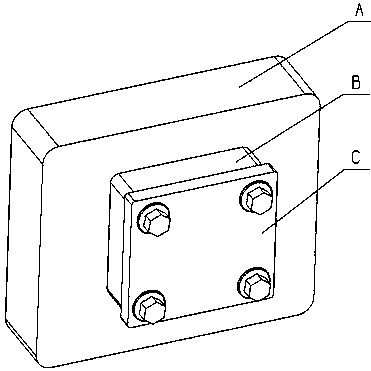

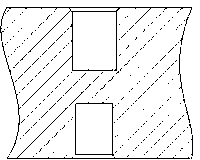

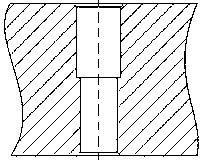

[0021] Embodiment 1, by adding an appropriate limit boss in the middle of the two pin holes, and optimizing the size combination, it can not only ensure the coaxiality of the two pin holes, but also limit the axial movement of the two positioning pins in an acceptable range. within range. Accurate positioning of parts is realized, which prevents the installation size of related parts from being out of tolerance due to inaccurate assembly positions of the parts themselves, which affects the quality of the whole machine. The positioning failure caused by the axial movement of the positioning pin during use is avoided, and the reliability of positioning is improved. It also avoids assembly difficulties caused by misalignment of parts or incorrect positioning pin installation operations, which affects production beats. The cylinder block 1, the gear chamber 2 and the gear chamber cover 3 are connected and fastened by connecting bolts 4, and are positioned and connected by using t...

Embodiment 2

[0022] Embodiment 2, a combined positioning pin hole structure of the present invention, including cylinder block 1, gear chamber 2, gear chamber cover 3, connecting bolts 4 (multiple), small positioning pins 5 (two), large positioning pins 6 ( two). The gear chamber 2 is installed on the cylinder block 1, the gear chamber cover 3 is installed on the gear chamber 2, and is fixed by connecting bolts 4, the gear chamber 2 is accurately positioned on the cylinder block 1 by the large positioning pin 6, and the gear chamber cover 3 is positioned by the small positioning pin The pin 5 is positioned precisely on the gear chamber 2 . The positioning pin hole on the gear chamber 2 adopts the structure of the present invention, the two pin holes are coaxial, and the center is designed with a spacer boss. A limited boss is designed in the middle of the two coaxial positioning pin holes. The boss height (relatively small pin hole) h, h is preferably (0.5~1). a=L-(a+b), b, c, and H ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap