Large motor stator installation structure and method

A large-scale motor and installation structure technology, applied in the manufacture of stator/rotor body, etc., can solve problems such as the inability to measure and adjust the clearance of the inner circle of the stator, and the difficulty in ensuring the coaxiality of the outer circle of the rotor and the inner circle of the stator, etc., to achieve a simple structure , easy to operate, ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

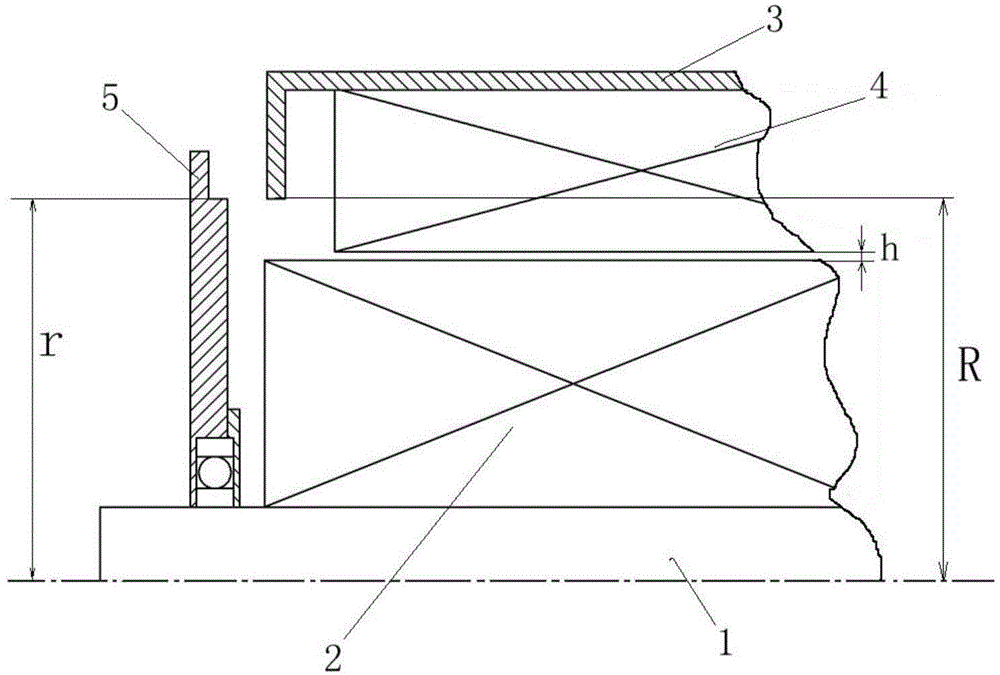

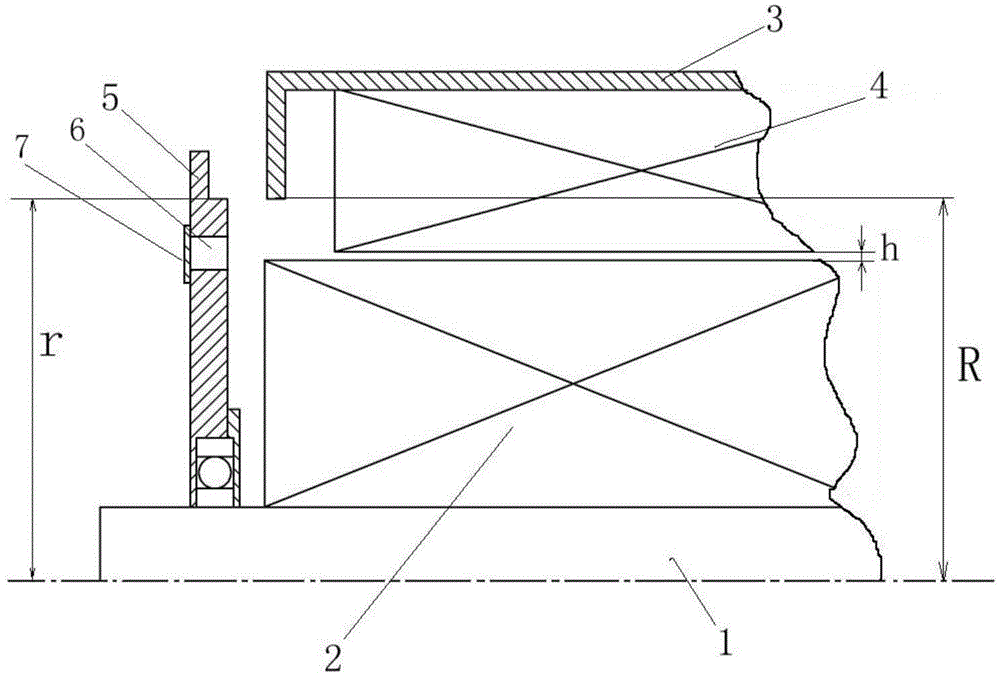

[0017] Attached figure 1 Schematic diagram of the stator installation structure of a large-scale motor in the prior art (for display convenience, attached figure 1 In the figure, 1 is the rotating shaft, 2 is the rotor, 3 is the stator housing, 4 is the stator, 5 is the rotor end cover, R is the rotor mounting hole radius, r is the positioning step radius, h It is the gap between the inner circle of the stator and the outer circle of the rotor. It can be seen from the figure that the prior art large-scale motor stator mounting structure uses the rotor mounting holes at both ends of the stator housing 3 as the positioning reference for the installation of the stator 4, that is, the rotor mounting holes coaxial with the inner circle of the stator are provided at both ends of the stator housing 3. A positioning step coaxial with the outer circle of the rotor is provided on the inner side of the rotor end cover 5. By precisely controlling the position and dimensional accuracy of the in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap