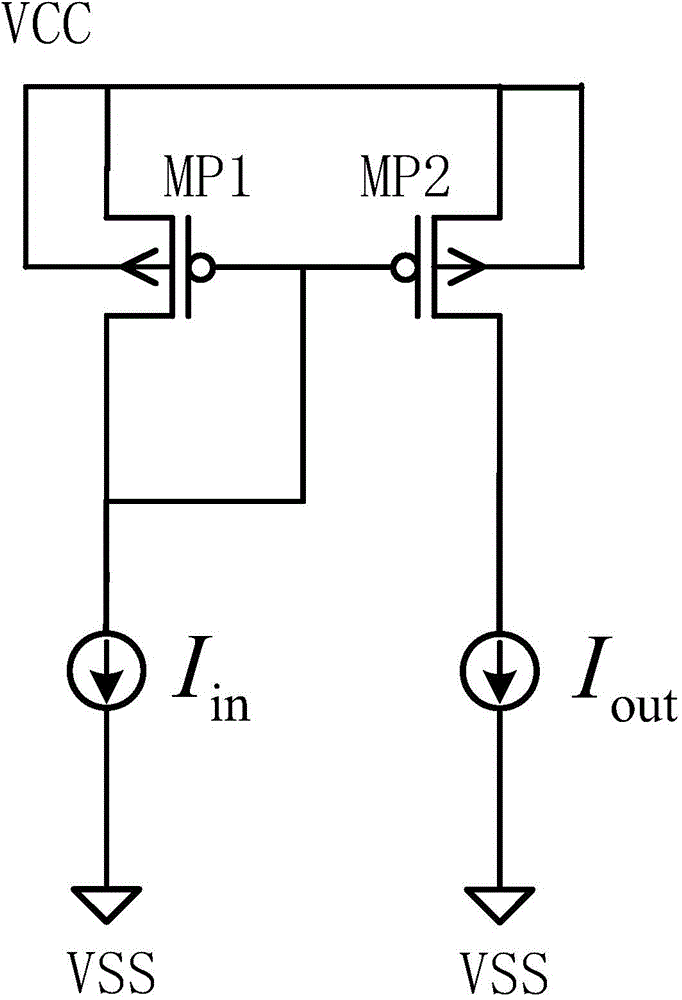

Current mirror for low supply voltage

A low power supply voltage, current mirror technology, applied in the field of current mirror, can solve the problems of unsuitable current mirror circuit and reduced voltage margin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

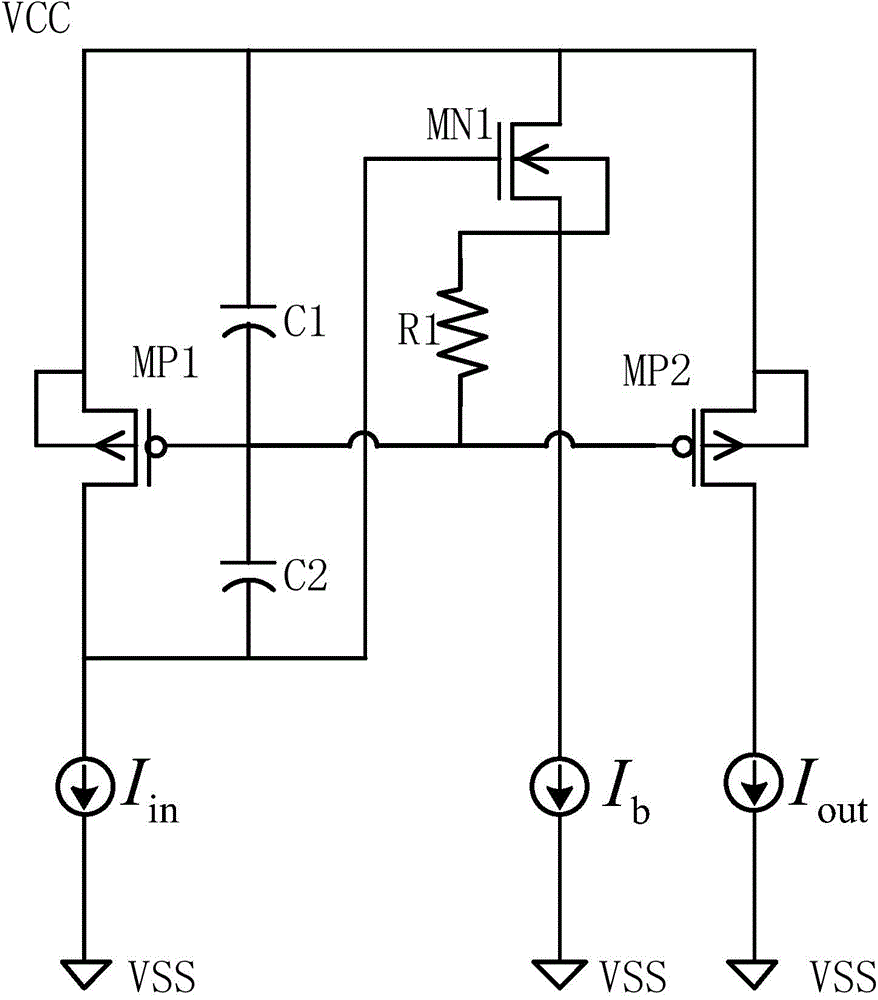

[0013] The specific embodiment of the present invention is described below in conjunction with accompanying drawing

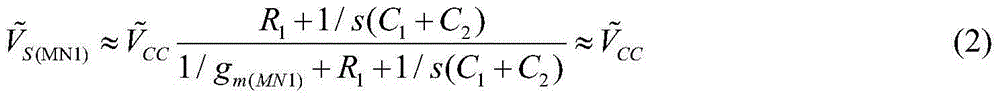

[0014] Such as figure 2 As shown, the current mirror of the present invention is composed of PMOS transistors MP1, MP2, NMOS transistor MN1, capacitors C1, C2, resistor R1, input current source, output terminal current source and bias current source; wherein, the source of MP1 is connected to Power supply VCC, its gate is connected to the gate of MP2, its drain is connected to the positive pole of the input current source; the negative pole of the input current source is grounded to VSS; the drain of MN1 is connected to the power supply VCC, its gate is connected to the positive pole of the input current source, and its source The pole is connected to the positive pole of the bias current source, and its substrate is connected to the connection point between the gate of MP1 and the gate of MP2 through R1; the negative pole of the bias current source is grounded t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap