Assembled tube-shell drawer type heat exchanger

A drawer type, heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the safety problems that cannot be solved, maintenance troubles, etc., to prevent leakage, improve Heat exchange effect, easy replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] In the following, the present invention will be further described with embodiments in conjunction with the drawings.

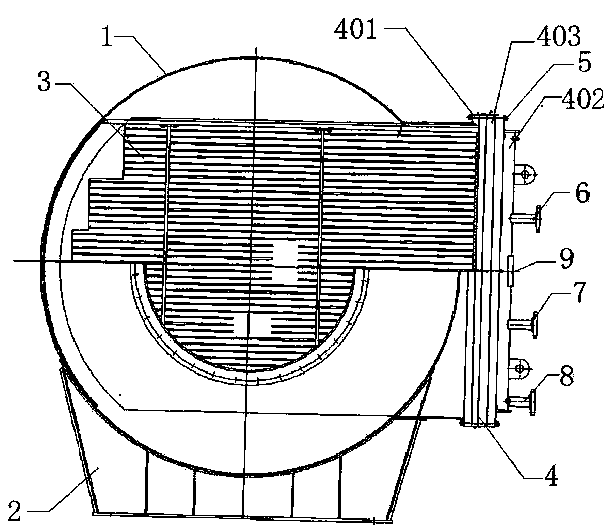

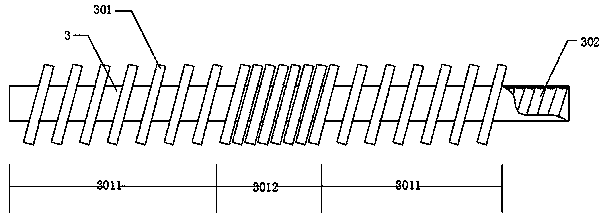

[0022] Such as figure 1 As shown, this embodiment includes a housing 1, a base 2, a heat exchange tube 3, and a heat exchange tube plate 4. The heat exchange tube plate 4 includes a front fixed tube plate 401 for fixing the heat exchange tube 3 and a clamp The rear clamped tube plate 402 immediately before the fixed tube plate 401 is arranged between the front fixed tube plate 401 and the rear clamped tube plate 402 is provided with a cavity that can accommodate the leakage of the heat exchange tube 3 to improve the safety of the equipment 403. The shape of the cavity 403 matches the front fixed tube plate 401 and the rear clamping tube plate 402, and the outer frame of the cavity 403 is in sealed connection with the front fixed tube plate 401 and the rear clamping tube plate 402, The cavity 403 is hollow inside. The front fixed tube plate 401, the empty cav

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap