Ball socket sample for simulating artificial intervertebral disc and preparation method and application of ball socket sample

A technology of intervertebral disc and ball socket, which is applied in the field of biotribological performance testing of artificial intervertebral discs, can solve the problems of time-consuming, high cost, and long cycle, and achieve the effect of solving difficult machining, wide application range, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1:

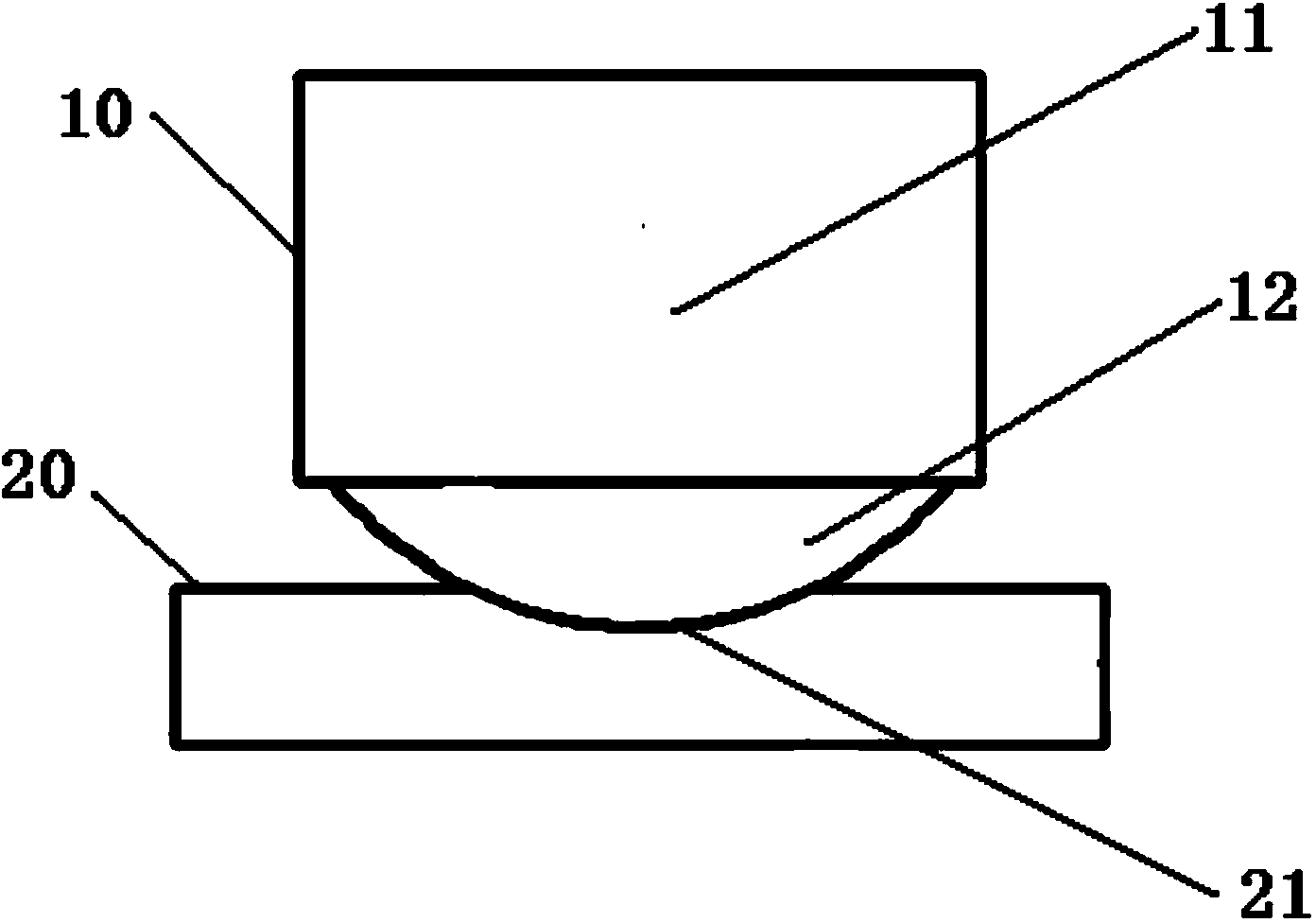

[0025] The structure diagram of the simulated artificial intervertebral disc ball and socket sample of the present invention is as figure 1 Said, it is composed of a ball head 10 and a ball socket 20. One end 11 of the ball head 10 is a cylinder, a cube, a cuboid or other geometric structures, and the protrusion 12 at the other end of the ball head 10 is a spherical shape. Or ellipsoidal, the ball socket 20 is a cylinder, a cube, a cuboid or other geometric structures. A groove 21 is provided on one end surface of the ball socket 20. The groove 21 and the protrusion 12 match in shape, and the ball head 10 It is in surface-to-surface contact with the ball socket 20 through the protrusion 12 and the groove 21, and the contact surface is a spherical or ellipsoidal spherical crown surface.

[0026] In this embodiment, the contact surface of the ball and socket structure design adopts a spherical spherical crown surface contact, and a very small wrapping depth (1.5mm)

Example Embodiment

[0027] Example 2:

[0028] The ultra-high molecular weight polyethylene powder with a particle diameter of 150μm and the zirconia nano-filled particles with a particle diameter of 150nm (with a filling amount of 5wt%) are stirred and evenly placed into a special mold, and heated, insulated and cooled on the hot press equipment The process completes the hot pressing of the powder. The temperature increase is in a low vacuum environment, the pressure is 10 MPa, and the temperature is increased to 200° C.; the holding time is 100 minutes; the temperature reduction is in a low vacuum environment, the pressure is 20 MPa, and the natural cooling is performed to obtain a ball head and a ball socket.

Example Embodiment

[0029] Example 3:

[0030] The ultra-high molecular weight polyethylene powder with a particle diameter of 200μm and the zirconia nano-filled particles with a particle diameter of 300nm (with a filling amount of 10wt%) are stirred and evenly placed into a special mold, and heated, insulated and cooled on the hot press equipment The process completes the hot pressing of the powder. The temperature increase is in a low vacuum environment, the pressure is 30 MPa, and the temperature is increased to 160° C.; the holding time is 90 minutes; the temperature reduction is in a low vacuum environment, the pressure is 30 MPa, and the natural cooling is performed to obtain a ball head and a ball socket.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap