Transmission shaft for machine tool transmission system

A machine tool transmission and transmission shaft technology, applied in the field of transmission shafts, to achieve good dynamic balance performance, simple structure, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

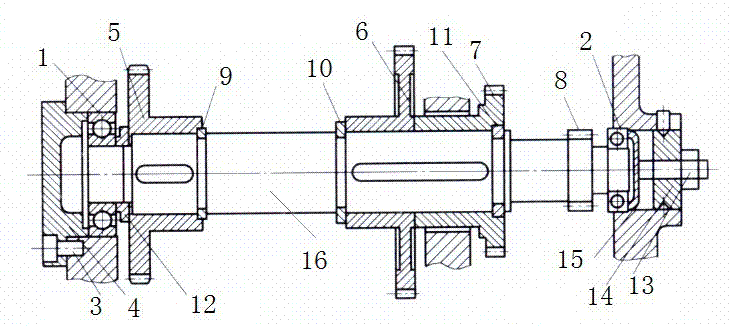

[0012] Such as figure 1 As shown, a transmission shaft of a machine tool transmission system includes a central shaft 16, one end of the central shaft 16 is provided with a front bearing 1, and the other end is provided with a rear bearing 2, and the outer side of the front bearing 1 is fixed with an end cover 4, and the rear bearing 2 A top cover 15 is fixed on the outside. Preferably, the end cover 4 is fixed on the front bearing 1 by screws 3 .

[0013] The central shaft 16 is sequentially provided with a first gear 5, a first retaining ring 9, a second retaining ring 10, a second gear 6, a third gear 7, and a third retaining ring 11 from the fro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap