Metal cutting tool

A metal cutting and cutting tool technology, applied in the field of mold manufacturing, can solve the problems of not being able to extend the tool handle at any time, inconvenient use, and low production efficiency, and achieve the effects of saving a lot of time, convenient use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

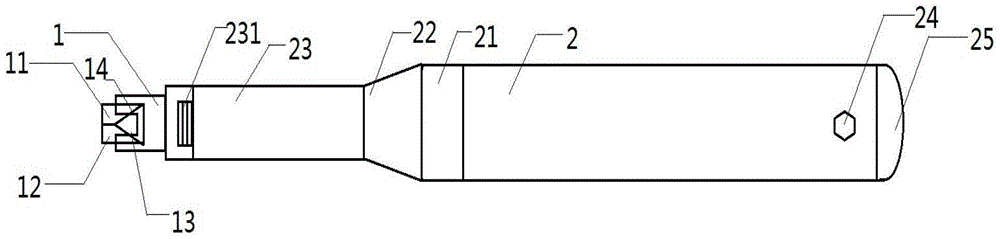

[0012] figure 1 It shows a schematic structural diagram of a metal cutting tool according to an embodiment of the present invention;

[0013] Such as figure 1 As shown, a metal cutting tool includes a cutter head 1 and a handle 2. The cutter head 1 is arranged at one end of the handle 2. The cutter head 1 includes an outer cutter 11, an inner hole cutter 12, a first sipe 13 and a second The knife groove 14 , the first knife groove 13 is perpendicular to the second knife groove 14 , and the knife handle 2 includes a knife head locking device 21 and a knife head fixing device 22 .

[0014] The knife handle 2 also includes an extension rod 23 , which is provided with a screw thread and adapted to the cutter head 1 .

[0015] The knife handle 2 also includes a buckle hole 24 and a knife head storage device 25 , and the buckle hole 24 fix

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap