Heater pipeline structure of roasting furnace

A heater and roaster technology, which is applied to burners, lighting and heating equipment, gas fuel burners, etc., can solve the problems of poor gas combustion effect and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below according to the drawings and embodiments.

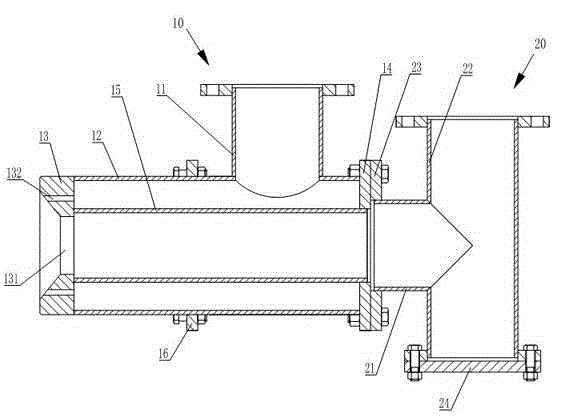

[0013] like figure 1 As shown, the heater pipe body structure of a baking furnace according to the embodiment of the present invention includes a secondary air inlet pipe 10 and a gas inlet pipe 20, and the secondary air inlet pipe 10 includes air valve connecting pipes 11 connected to each other. And air inlet main pipe 12, one end of described air inlet main pipe 12 is fixedly connected with burner 13, and the other end of described air inlet main pipe 12 is provided with connecting flange A 14; Described air inlet main pipe 12 is provided with inner pipe 15 , one end of the inner pipe 15 is fixedly connected to the burner 13, and the other end of the inner pipe 15 is fixedly supported by the connecting flange 14; the burner 13 has a gas nozzle 131 and an air nozzle 132, One end of the inner pipe 15 communicates with the gas nozzle 131 , and the other end of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap