Ball mill with non-cylindrical inner cavity wall

A technology in the inner cavity wall and in the cylinder, which is applied in the direction of grain processing, etc., can solve the problems of no large-scale axial impact and grinding, less collision and friction between balls and raw materials, and large blindness of balls. Grinding effect, short ball milling cycle and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand more clearly the technical idea claimed in the present invention.

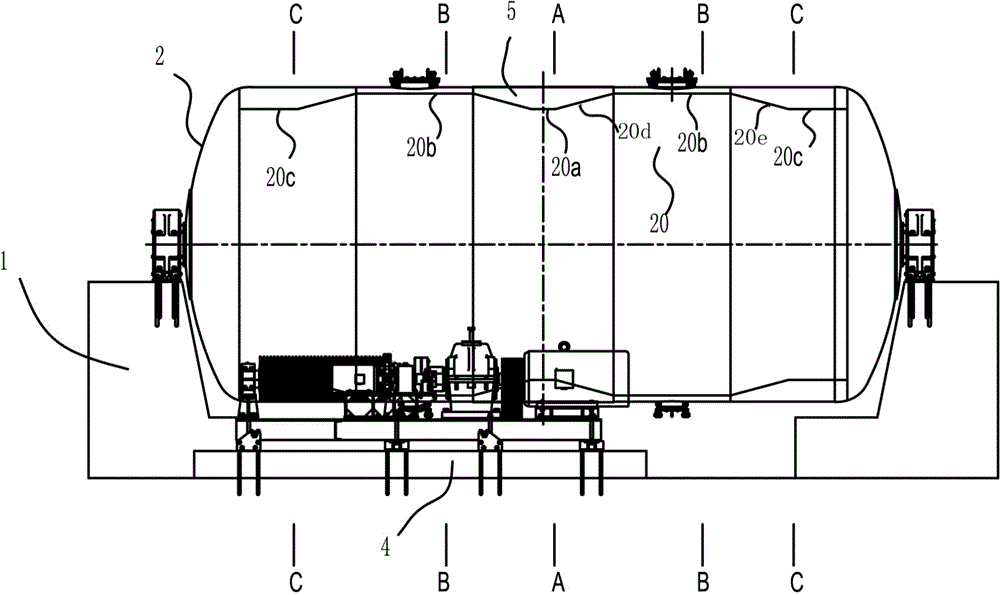

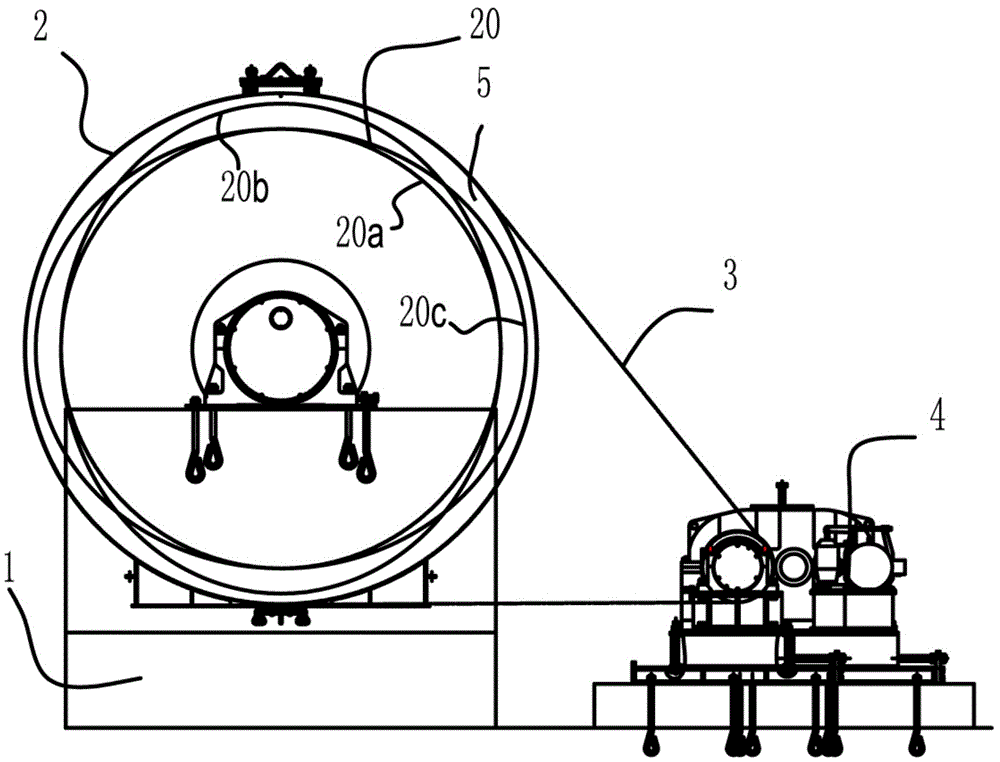

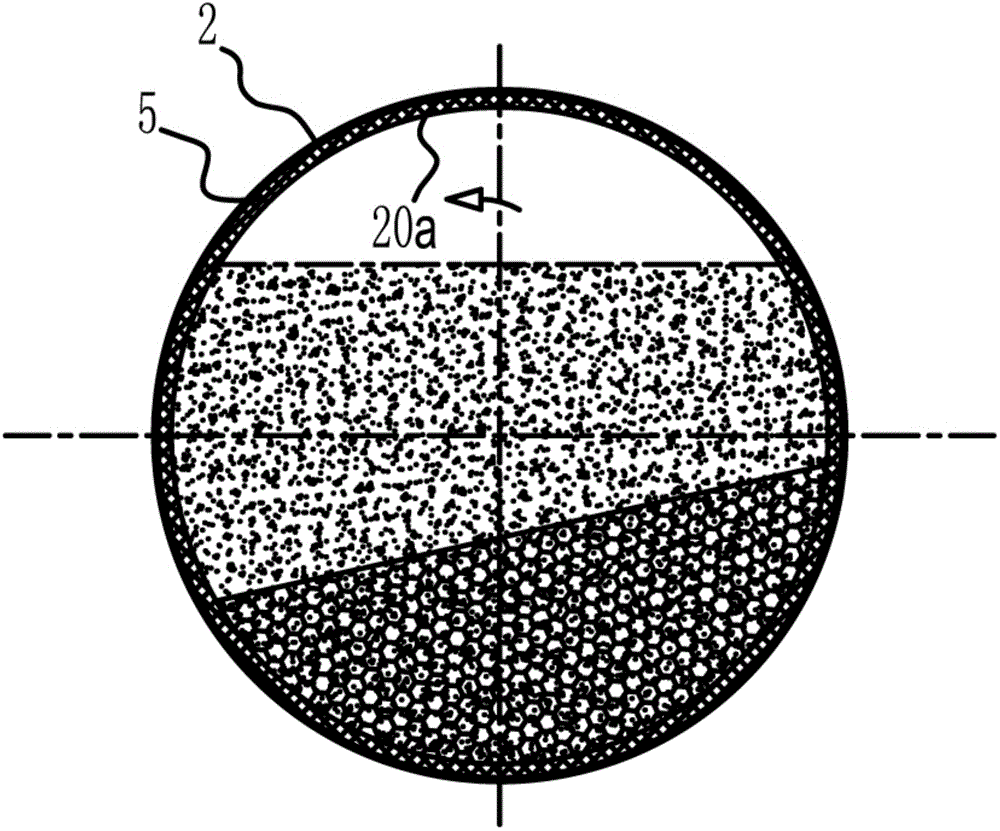

[0020] Such as Figure 1-5 The cylinder inner wall of the present invention shown is a non-cylindrical ball mill, comprising a frame 1, a cylinder 2, a transmission belt 3 and a driving device 4, the cylinder 2 is fixed on the frame 1 through a bearing, and the cylinder 2 passes through The transmission belt 3 is connected with the driving device 4 to realize the rotation of the cylindrical body 2 driven by the driving device 4 . The inner cavity of the cylinder body 2 is used to hold ball stones, raw materials, slurry, etc., and its inner cavity wall 20 is a segmented irregular shape, including a circular cross-section inner cavity wall 20a arranged in the middle of the cylinder body 2, symmetrically arranged The first elliptical section inner cavit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap