Fixed length automatic feeding device based on band sawing machine

A technology of automatic feeding and band sawing machine, used in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of different lengths of bars, difficult to ensure accuracy, and large labor, and improve product quality and operation. Ease, reduce labor intensity and the effect of labor volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

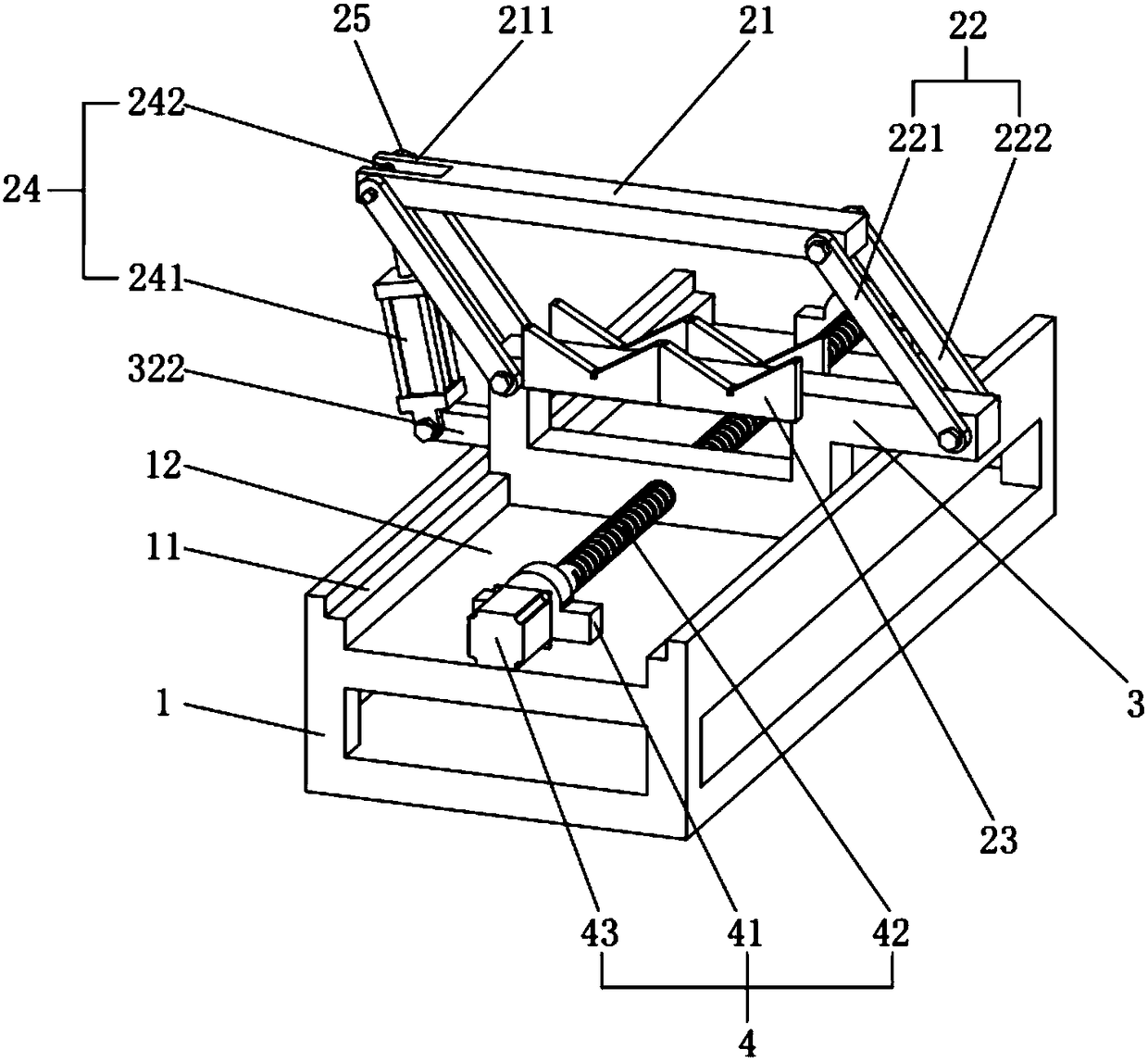

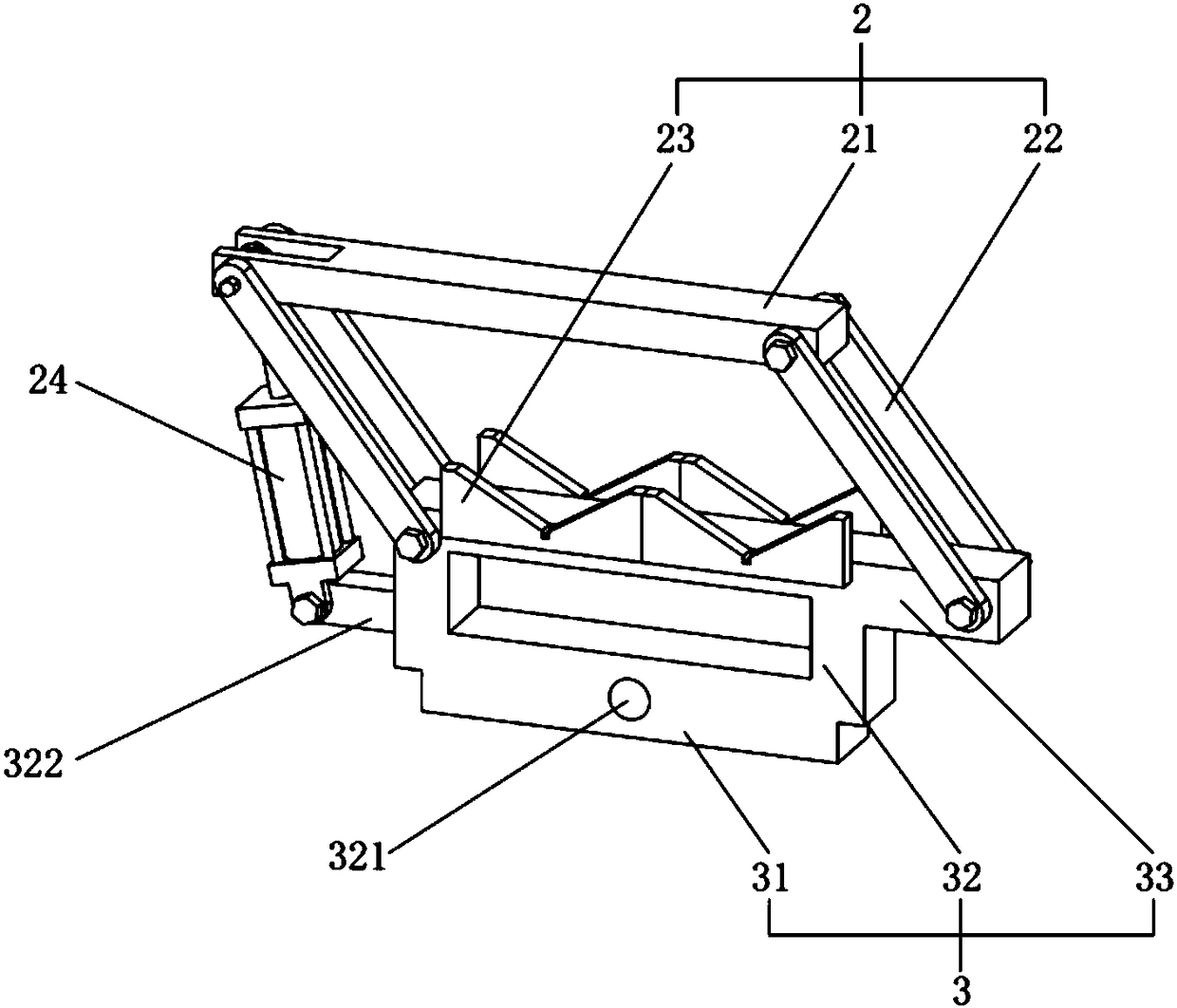

[0016] Please refer to figure 1 , the embodiment of the present invention provides a fixed-length automatic feeding device based on a band sawing machine, which mainly includes a frame 1, a clamping mechanism 2 and a material delivery slide 3, and the clamping mechanism is installed on the material delivery slide , the material delivery slide 3 is slidably arranged on the frame 1 .

[0017] Please refer to figure 1 with figure 2 Specifically, the frame 1 is recessed from top to bottom with a storage cavity 12, and the walls of the storage cavity 12 on the left and right sides are provided with sliding grooves 11. The material delivery slide 3 includes a main body 32, beams 33 located on the upper and lower sides of the main body 32 and a sliding part 31

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap