Improved lead-acid cell medium dense polar plate separating and brushing integrated machine

A lead-acid battery, an improved technology, applied in the direction of lead-acid battery electrodes, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of uneven stacking of plates, untreated side frames of plates, and side brushes Insufficient and other problems, to achieve the effect of cleaning the lead powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

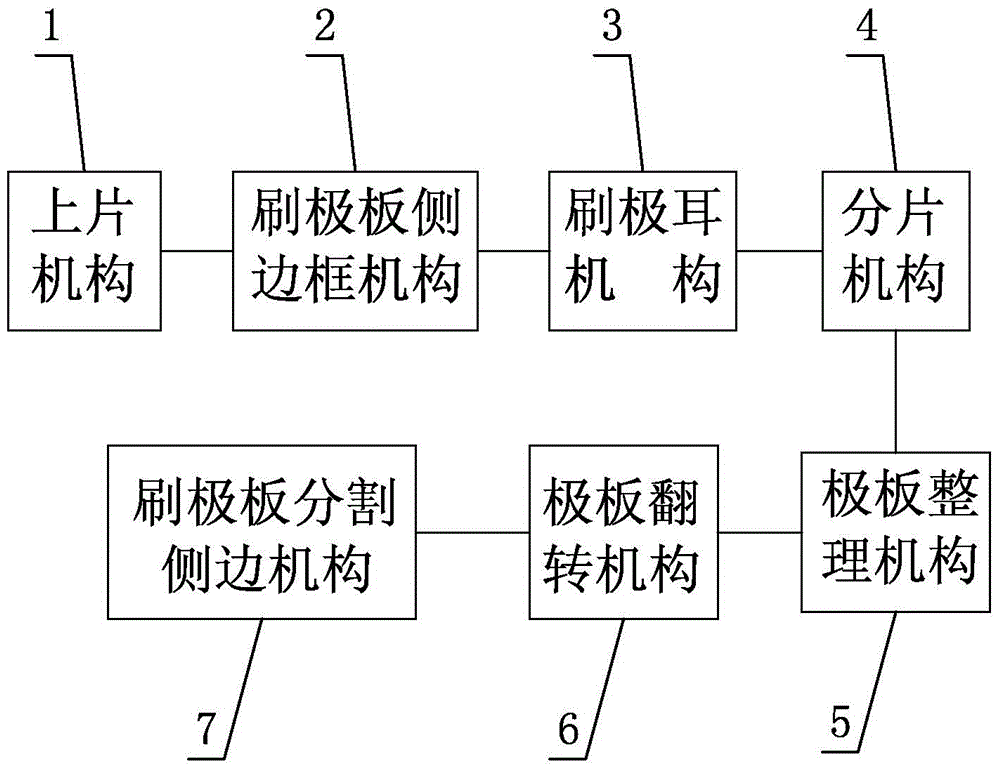

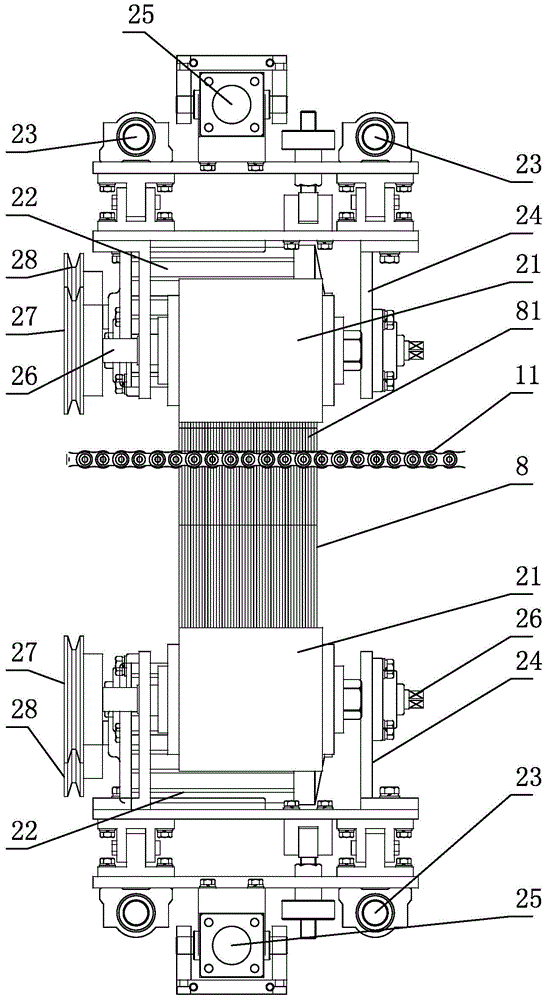

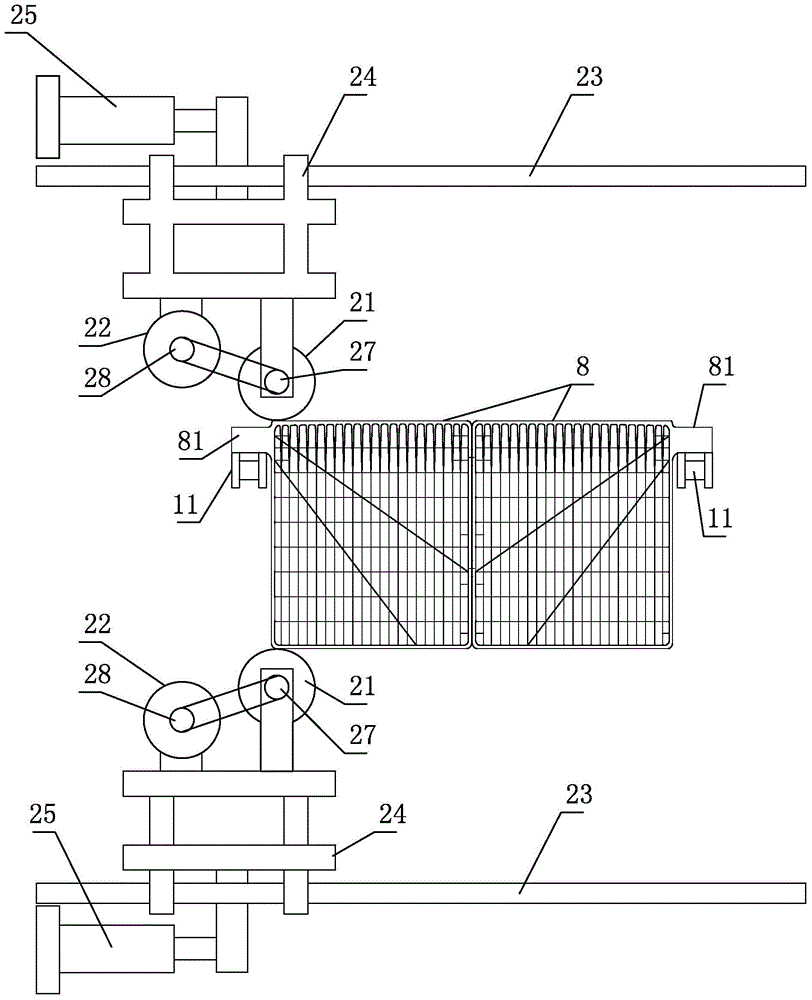

[0030] Such as Figures 1 to 13 As shown, the improved lead-acid battery medium-density electrode plate separation and brushing machine includes a loading mechanism 1 for conveying two connected pole plates 8, wherein the loading mechanism 1 includes two conveyor chains arranged side by side I11, there is an interval between the two transmission chains I11, in the two plates 8 connected together, the tab 81 of each plate 8 is located on the side of the plate away from the other plate, and the two plates are connected The pole plates 8 together are placed on one transmission chain I11 through one tab 81, the other tab 81 is placed on another transmission chain I11, and then vertically suspended between the two transmission chains I11, and the two transmission chains I11 move synchronously to The two connected pole plates 8 suspended vertically between the two conveyor chains I11 are transported; it also includes two adjacent sides for the side where the lug of the pole plate 8 con

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap