Propelled type automatic feeding device and feeding method for large-scale straw gas

An automatic feeding and push-type technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of tear resistance, wear resistance and cut resistance rubber composition difficulties, conflicts, etc. Achieve the effect of convenient feeding and high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

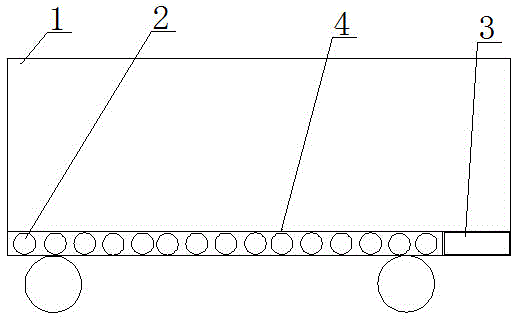

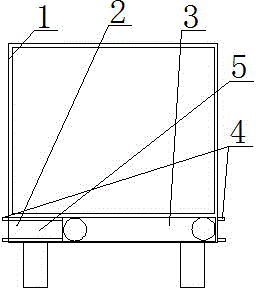

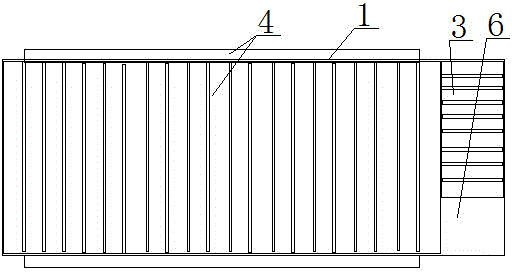

[0024] Embodiment 1: as figure 1 , 2 , 3, and 4, a large-scale straw biogas propulsion type automatic feeding device includes a carriage 1 with a traveling mechanism, a front side of the front part of the carriage 1 is provided with a front discharge port 5, and the carriage 1 The bottom front outlet is provided with a lower outlet 6, the front outlet 5 and the lower outlet 6 are provided with hinged sealing plates, the front outlet 5 and the lower outlet 6 The width matches the width of the conveyor outside the compartment. The bottom end of the compartment 1 is provided with a longitudinal belt conveyor 3 for transporting the straw material to the lower outlet. To the lower outlet 6 and the transverse belt conveyor 2 on the longitudinal belt conveyor 3.

[0025] Both the longitudinal belt conveyor 3 and the transverse belt conveyor 2 are installed horizontally in the compartment.

[0026] The height of the longitudinal belt conveyor 3 is not higher than the height of the ...

Embodiment 2

[0028] Embodiment 2: Embodiment 1: as figure 1 , 2 , 3, and 4, a large-scale straw biogas propulsion type automatic feeding device includes a carriage 1 with a traveling mechanism, a front side of the front part of the carriage 1 is provided with a front discharge port 5, and the carriage 1 The bottom front outlet is provided with a lower outlet 6, the front outlet 5 and the lower outlet 6 are provided with hinged sealing plates, the front outlet 5 and the lower outlet 6 The width matches the width of the conveyor outside the compartment. The bottom end of the compartment 1 is provided with a longitudinal belt conveyor 3 for transporting the straw material to the lower outlet. To the lower outlet 6 and the transverse belt conveyor 2 on the longitudinal belt conveyor 3.

[0029] Both the longitudinal belt conveyor 3 and the transverse belt conveyor 2 are installed horizontally in the compartment.

[0030] The height of the longitudinal belt conveyor 3 is not higher than the ...

Embodiment 3

[0032] Embodiment 3: as figure 1 , 2, 3, and 4, a large-scale straw biogas propulsion type automatic feeding device includes a carriage 1 with a traveling mechanism, a front side of the front part of the carriage 1 is provided with a front discharge port 5, and the carriage 1 The bottom front outlet is provided with a lower outlet 6, the front outlet 5 and the lower outlet 6 are provided with hinged sealing plates, the front outlet 5 and the lower outlet 6 The width matches the width of the conveyor outside the compartment. The bottom end of the compartment 1 is provided with a longitudinal belt conveyor 3 for transporting the straw material to the lower outlet. To the lower outlet 6 and the transverse belt conveyor 2 on the longitudinal belt conveyor 3.

[0033] Both the longitudinal belt conveyor 3 and the transverse belt conveyor 2 are installed horizontally in the compartment.

[0034] The height of the longitudinal belt conveyor 3 is not higher than the height of the t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap