Device for simply detecting Brinell hardness of metal material

A material cloth and metal technology, which is applied in the field of devices for simply detecting the Brinell hardness of metal materials, can solve the problems of low cost, time-consuming and labor-intensive efficiency, etc., and achieves the effects of low cost, simple structure, and simple and easy detection operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

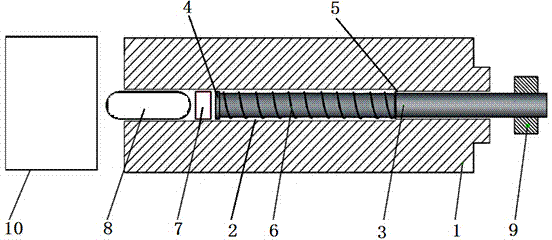

[0009] Embodiments of the present invention: the structure of the device for easily detecting the Brinell hardness of metal materials is as follows figure 1 As shown, it includes a cylinder shell 1, the axial middle part of the cylinder shell 1 is a smooth through-hole structure 2, and an impact rod 3 is arranged in the through hole of the cylinder shell 1, and the end of the impact rod 3 is in the cylinder shell 1 In addition, a round table 4 is provided at the front end of the impact rod 3; a limiting boss 5 is provided in the through hole structure 2, and a spring 6 surrounding the impact rod 3 is arranged between the round table 4 and the limiting boss 5; The front end of 3 is provided with standard sample test block 7, is provided with push rod 8 at the other end of standard sample test block 7, and the two ends of push rod 8 are arc-shaped, and its arc radius is not greater than the diameter of push rod 8; 3 is provided with a handle 9 at the end. In this embodiment, the ha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap