Table type drilling and tapping dual-purpose machine tool for vehicle five-wheel fittings

An accessory, dual-use technology, applied in vehicle parts, metal processing machinery parts, automatic control devices, etc., can solve the problems of inconvenient production and maintenance, broken shafts, etc., and achieve the effect of long service life and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

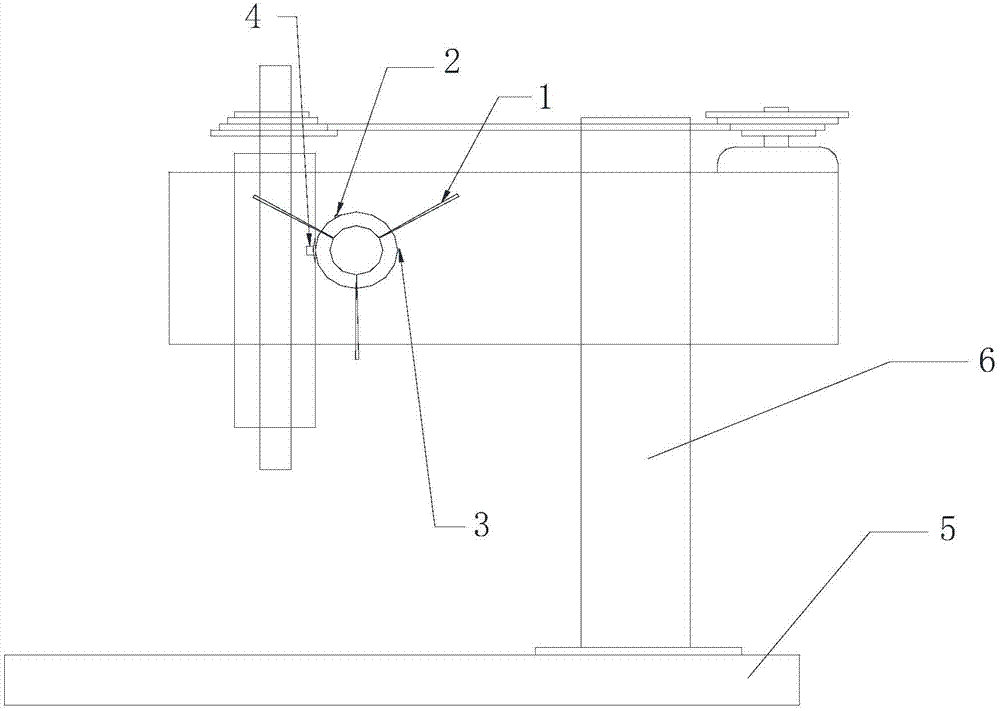

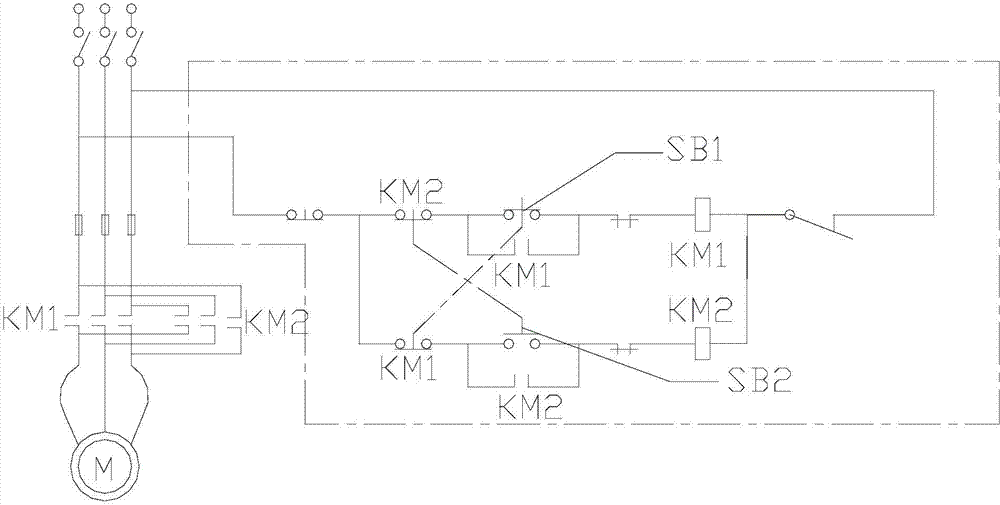

[0021] Such as figure 1 As shown, a desktop drilling and tapping dual-purpose machine tool for five-wheel parts of automobiles, including a workbench base 5, a lifting column 6, a lifting mechanism, a tower pulley, a machine tool spindle, a spindle lifting handle 1, a reset scroll spring, etc. , also includes an electrical control box and a drilling and tapping switch, the electrical control box and the drilling and tapping switch are fixed on the side wall of the lifting mechanism, the electrical control box is provided with a motor reversible circuit, and the motor is reversible The c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap