Soy sauce preparation method using maohualu (salt brine separated out in the pickling process of fermented bean curd semifinished product) to replace saline water

A technology of marinated marinade and soy sauce, applied in the directions of food preparation, application, food science, etc., can solve the problem that the value of marinated marinade is not fully utilized, and achieve the effects of soft taste, improved utilization of raw materials, and obvious umami taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0013] Mycelia autolysis experiment 1: take 1500g of rhubarb, divide it into 4 Erlenmeyer flasks, place it in a constant temperature incubator at 20°C, 30°C, 40°C, and 50°C, ferment for 10 days respectively, and detect the marinade The physical and chemical properties of halogen autodissolution, the results are shown in Table 1.

[0014]

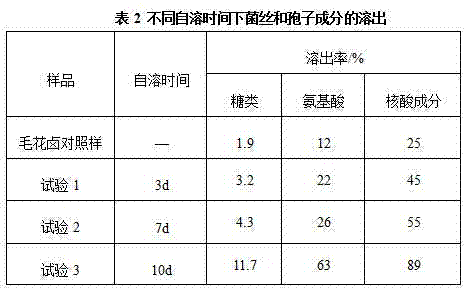

[0015] Mycelia autolysis experiment 2: take 500g of rhododendron, divide them into three different conical flasks, put them in a constant temperature incubator at 30-50°C, ferment for 3d, 7d, and 10d respectively, and test the autolysis of rhizoma rhizome. The physical and chemical properties after dissolution are shown in Table 2.

[0016]

[0017] Mycelia autolysis experiment 3: take 500g of the rhododendron and divide it into three different triangular flasks, adjust the initial pH of the rhododendron in different triangular flasks, so that the pH of the rhododendron in the three triangular flasks 3, 5, and 8 respectively. The three t

Embodiment 1

[0021] Autodissolution treatment of rhododendron: put the rhizoma rhizome in a triangular flask, adjust the initial pH of the rhododendron to 8, place it in a constant temperature incubator at 40°C, and the autolysis time is 3 days respectively.

[0022] Preparation of soy sauce Oji: Soybean meal is placed in a cooking pot at 110°C, steamed for 20 minutes, then mixed with flour at a mass ratio of 1:0.2, cooled and inoculated with Aspergillus oryzae with 0.02% (w / w) of soybean meal weight, koji making, and soy sauce Daqu. The koji making conditions are as follows: the culture temperature is 28°C, the humidity is 70%, and the culture time is 40h.

[0023] Fermentation: Soy sauce Daqu is mixed with autolyzed maohua brine, the volume-to-mass ratio between autolyzed maohua brine and soy sauce daqu is 2, using the high-salt dilute soy sauce brewing method (GB18186-2000) to ferment for 180 Days later, press and filter to get soy sauce.

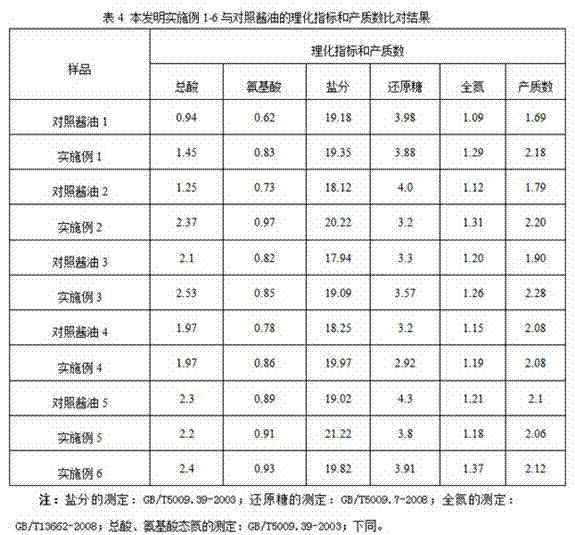

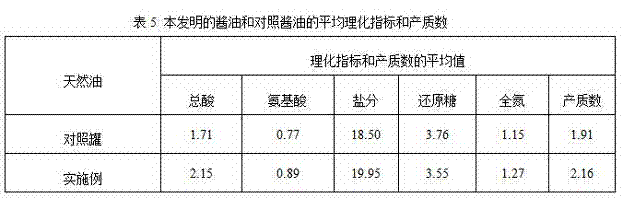

[0024] Detection of physical and chemical ind

Embodiment 2

[0026] Autodissolution treatment of rhododendron: put the rhizoma rhizome in a triangular flask, adjust the initial pH of the rhododendron to 5, place it in a constant temperature incubator at 40°C, and the autolysis time is 10 days respectively.

[0027] Preparation of soy sauce Oji: Soybean meal is placed in a cooking pot at 115°C, steamed for 10 minutes, then mixed with flour at a mass ratio of 1:0.8, cooled and inoculated with Aspergillus oryzae with 0.08% (w / w) of soybean meal weight, koji making, and soy sauce Daqu. The koji making conditions are as follows: the culture temperature is 30°C, the humidity is 80%, and the culture time is 60h.

[0028] Fermentation: Soy sauce Daqu is mixed with autolyzed Maohua brine, the volume-to-mass ratio between autolyzed Maohua brine and soy sauce Daqu is 3, and the high-salt dilute soy sauce brewing method (GB18186-2000) is used to ferment for 180 Days later, press and filter to get soy sauce.

[0029] Detection of physical and chemi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap