Long-line repair method of COA array substrate

A repair method and technology to be repaired, applied in nonlinear optics, instruments, optics, etc., can solve the problems of long-term metal falling off easily, achieve the effect of solving long-term metal falling off and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

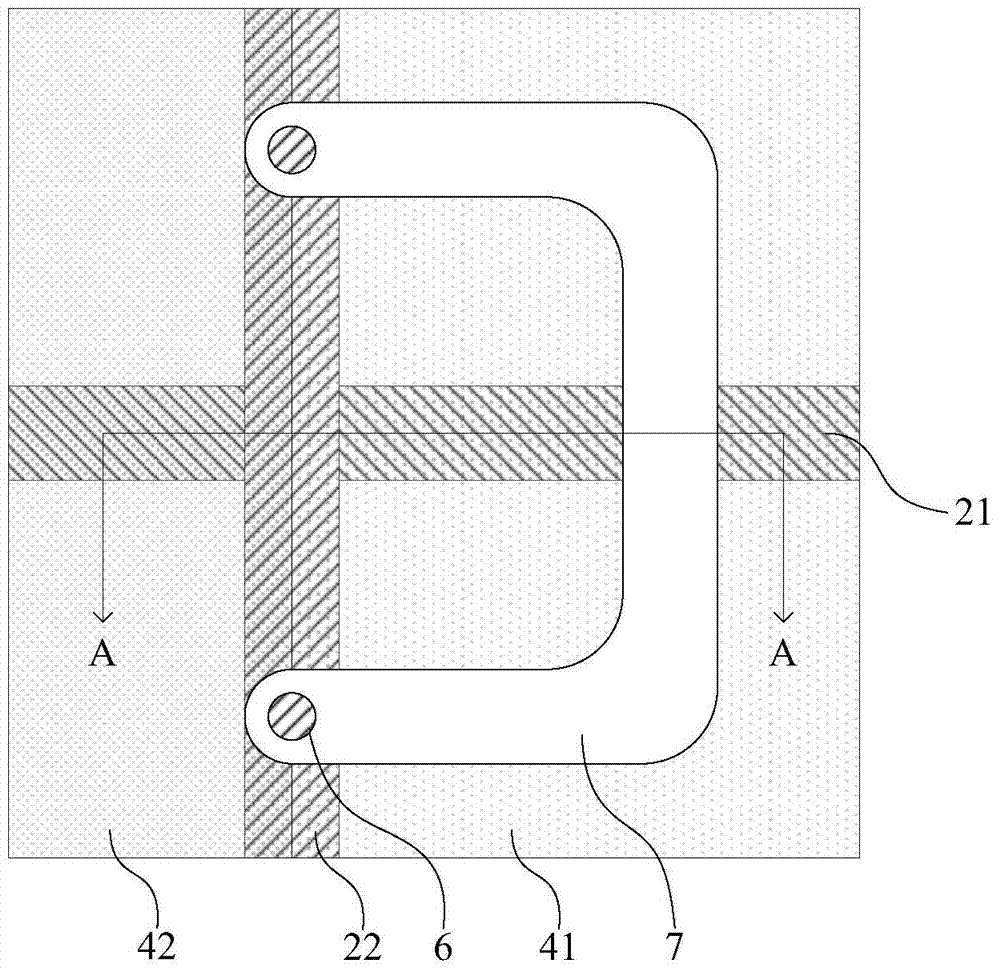

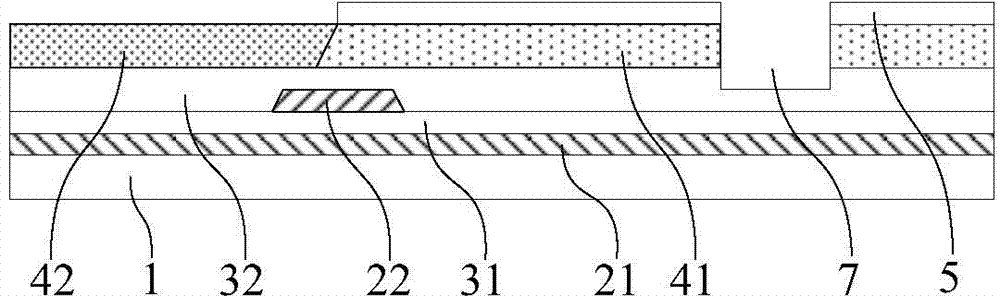

[0037] An embodiment of the present invention provides a method for repairing a long line of a COA array substrate, which can be applied to a long line repair process of a COA array substrate. Such as figure 1 and figure 2 As shown, the COA array substrate in this embodiment includes a glass substrate 1, a scanning line 21 located on the first metal layer, a data line 22 located on the second metal layer, a first insulating layer 31, a second insulating layer 32, a color resist 41. Color resistance 42. Transparent electrode 5. Wherein, the first insulating layer 31 and the second insulating layer 32 are usually made of silicon nitride, the transparent electrode 5 is usually made of indium tin oxide (ITO), and the data line 22 is the metal line to be repaired in this embodiment.

[0038] After the long-line area is determined, the long-line repair can be carried out. The long-line repair method includes:

[0039] S11 : opening via holes 6 at both ends of the long line area to

Embodiment 2

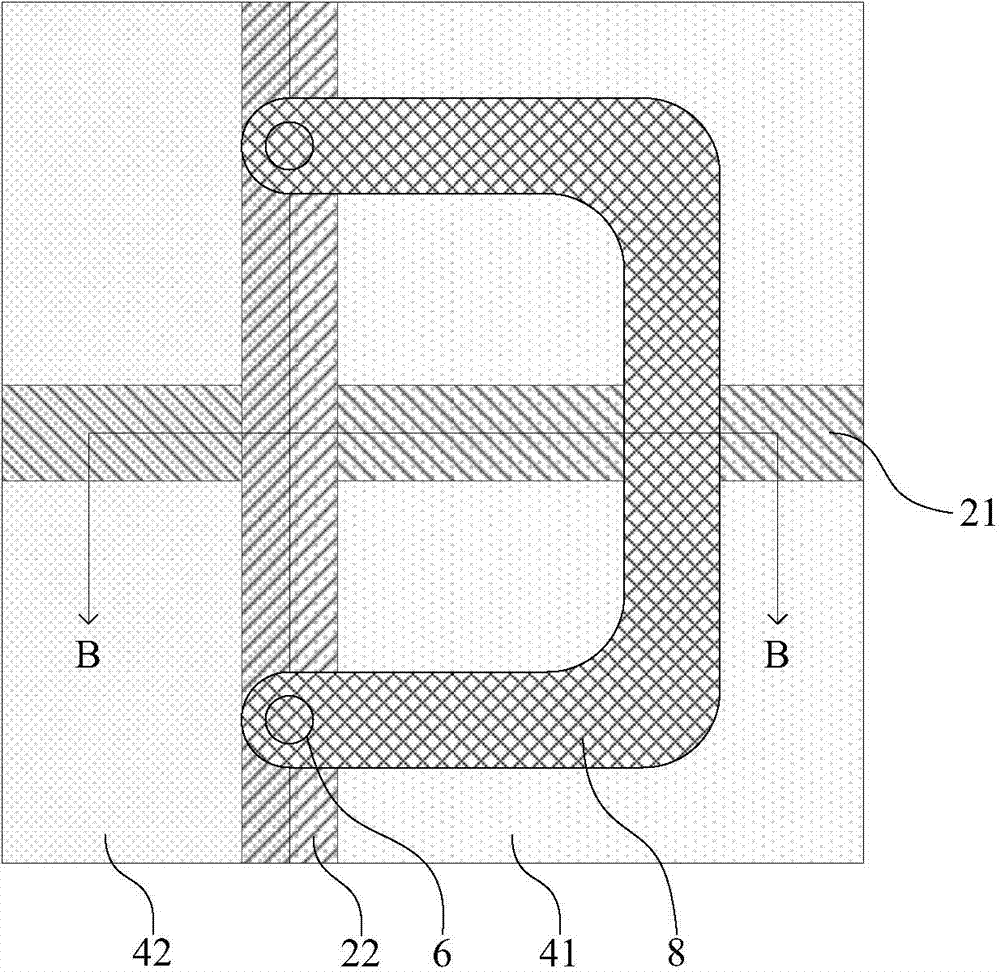

[0048] Such as Figure 5 and Figure 6 As shown, the COA array substrate in this embodiment is basically the same as that in Embodiment 1, including a glass substrate 1, scanning lines 21 located on the first metal layer, data lines 22 located on the second metal layer, a first insulating layer 31, and a second metal layer. Two insulating layers 32 , color resist 41 , color resist 42 , transparent electrode 5 . The difference between this embodiment and the first embodiment is that the metal line to be repaired in this embodiment is the scan line 21 .

[0049] The long line repair method provided by the embodiment of the present invention includes:

[0050] S21: Opening first via holes 61 at both ends of the first long line region to expose the scan lines 21 .

[0051] Specifically, a laser is used to drill holes at both ends of the first long line region, and the formed first via hole 61 should penetrate the first insulating layer 31, the second insulating layer 32, the color

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap