Power output propeller

A technology of power take-off and power take-off wheel, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

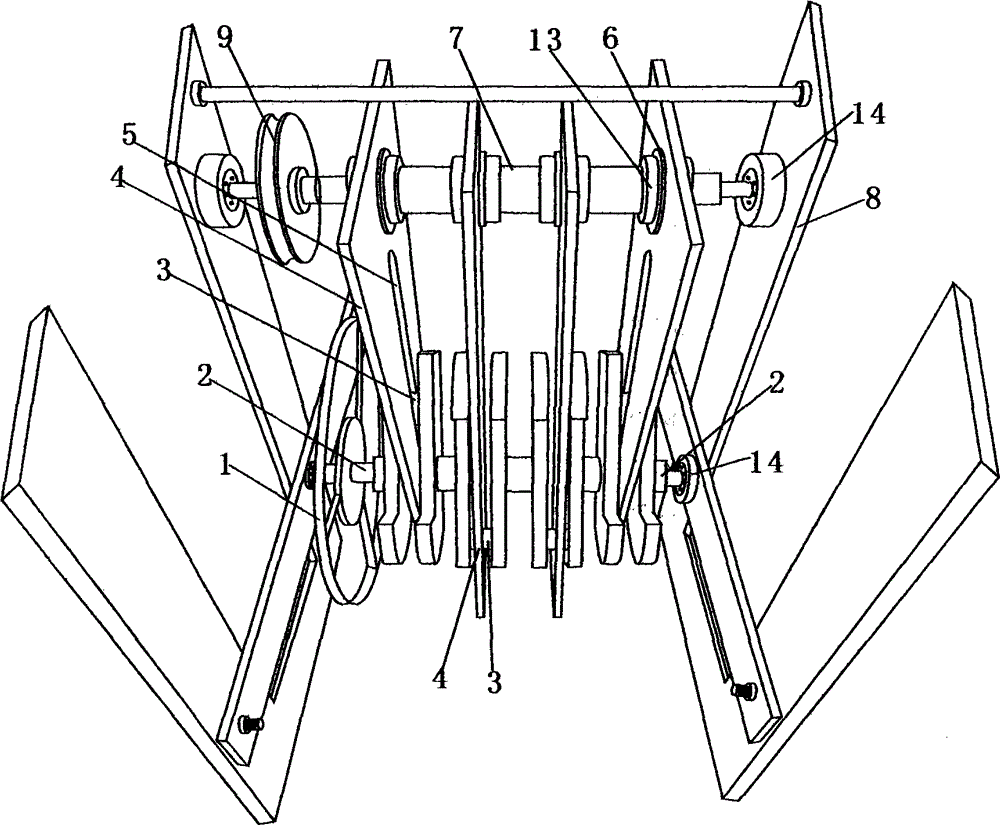

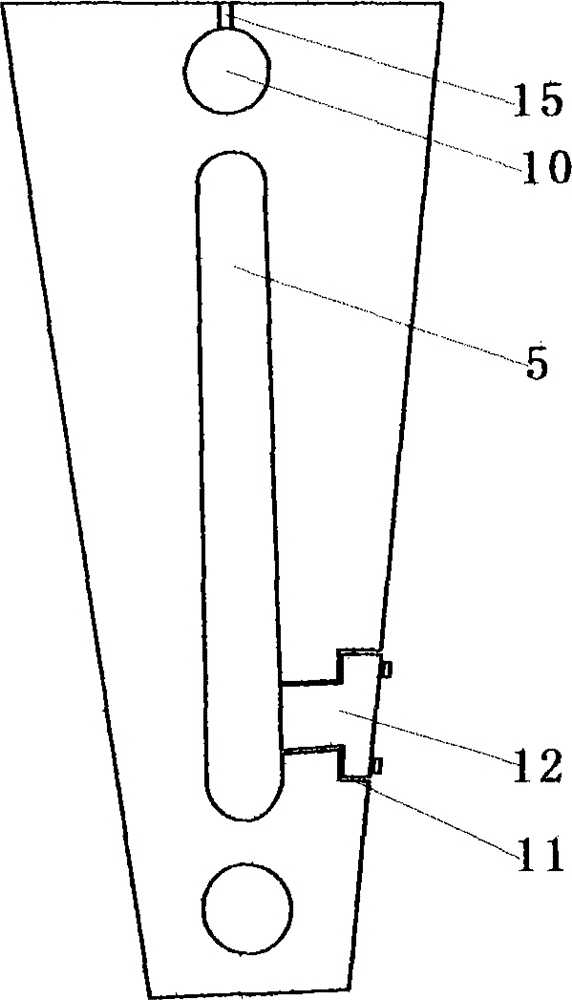

[0013] Example: such as figure 1 As shown, the power output propeller is composed of a power input wheel 1, a crankshaft 2, four connecting rocker arms 4, a one-way shaft 7, a power output wheel 9 and a bracket 8, and the crankshaft 2 and the one-way shaft 7 are fixed on the bracket through bearings 8, the one-way shaft 7 and the crankshaft 2 are in an up-and-down positional relationship, and the top of the connecting rocker arm 4 is provided with a one-way bearing installation hole 10, which is installed on the one-way shaft 7 through the one-way bearing 6, and fastening nuts 13 are used on both sides of the joint Fasten the connection. A chute track 5 is set on the center of the connecting rocker arm 4, which is connected in series with the bellcrank 3 of the crankshaft 2. The bellcrank 3 is located in the chute track 5 and can move along the chute track. The four connecting rocker arms are installed side by side according to this structure to form a linkage overall. The powe

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap