Combined septic tank

A septic tank and side plate technology, applied in the field of combined septic tanks, can solve the problems of inconvenient assembly and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

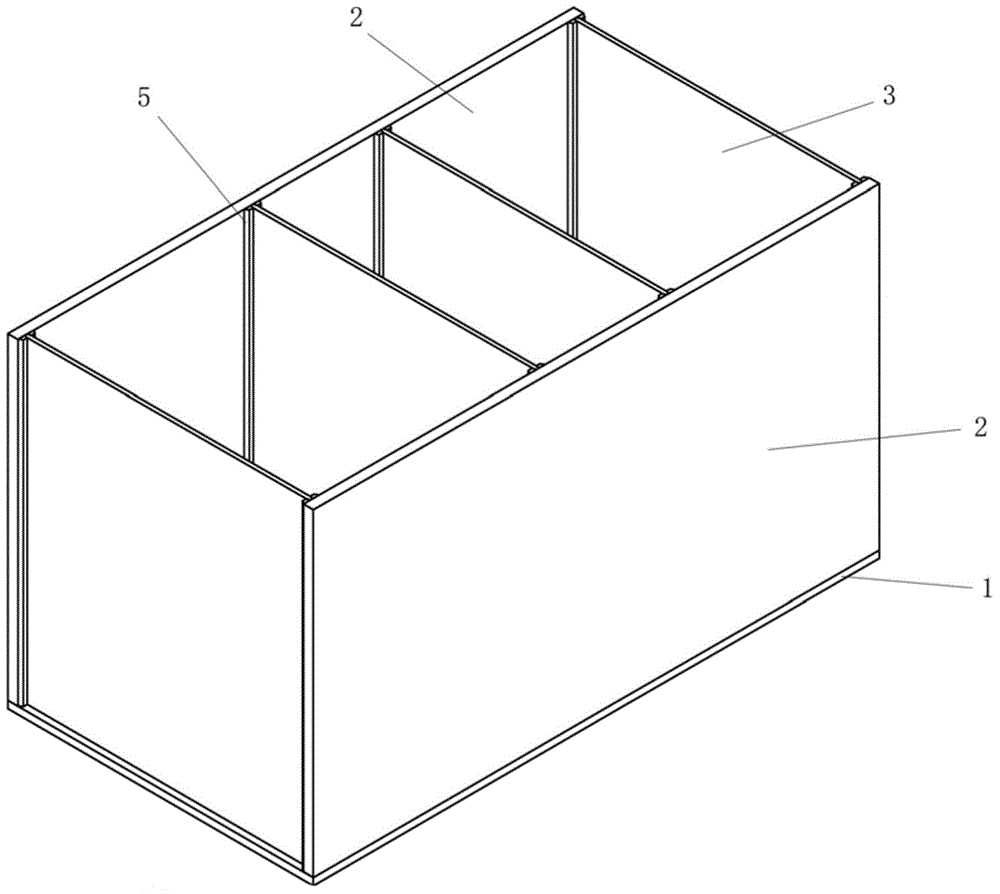

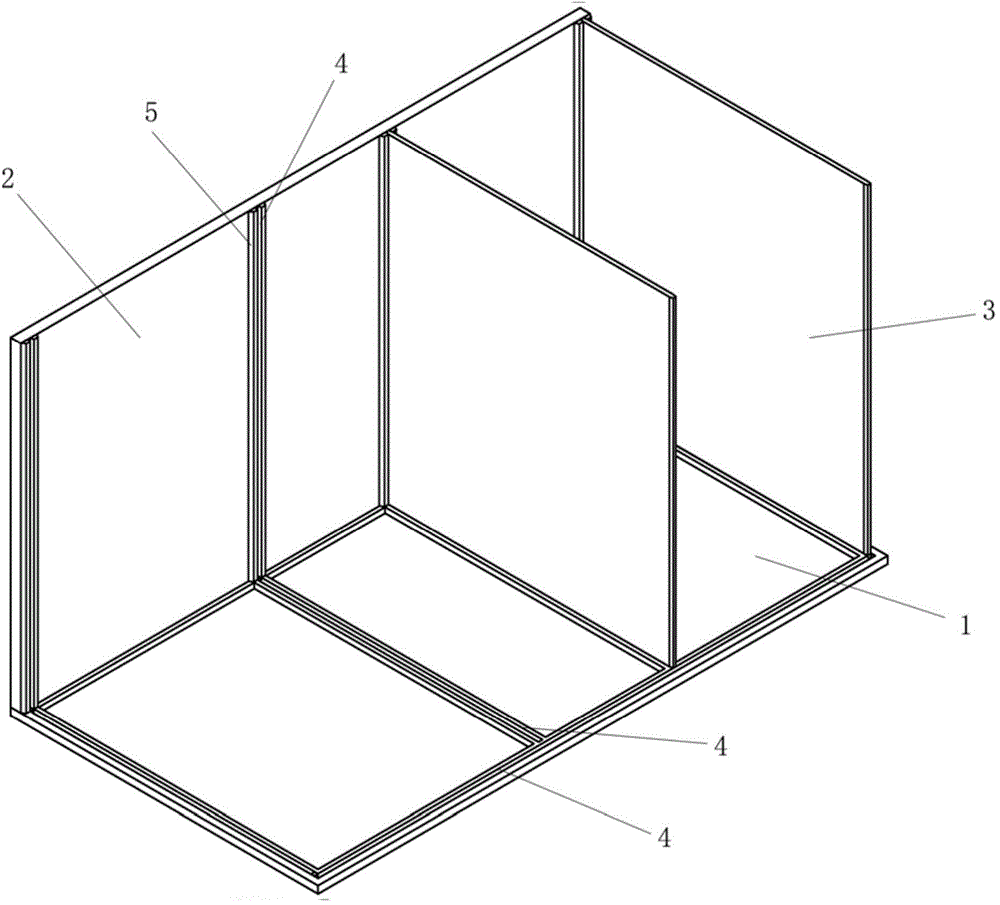

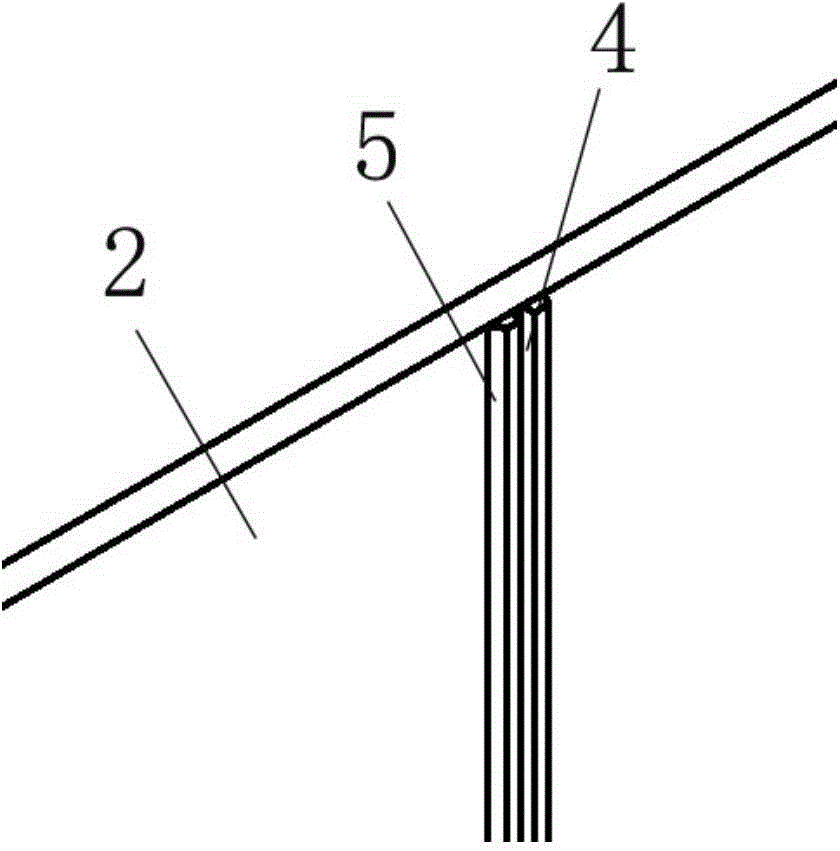

[0014] Such as Figures 1 to 3 Shown is a preferred embodiment of the combined septic tank of the present invention, the combined septic tank mainly includes a bottom plate 1, two side plates 2 and four partitions 3, the two side plates 2 are arranged on the top surface of the bottom plate 1, Two side plates 2 are arranged oppositely, and four partitions 3 are arranged between the two side plates 2, between the bottom plate 1 and the side plate 2, between the bottom plate 1 and the partition 3, and between the side plate 2 and the partition 3 Each side plate 2 is facing the other side plate 2 and is provided with a groove 4 at the position where each partition plate 3 is located, and the top surface of the bottom plate 1 is on each side. The positions of each partition 3 are also provided with grooves 4, the side of the partition 3 is stuck in the groove 4 of the side plate 2, and the bottom of the partition 3 is stuck on the top of the bottom plate 1 facing the position of the p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap