Washing machine and circulating water-saving filter device with self-cleaning function for washing machine

A filter device and self-cleaning technology, which is applied to washing devices, other washing machines, household appliances, etc., can solve the problems of no cleaning function, blockage of filter devices, and influence on water cycle treatment, etc., and achieve simple structure, energy saving, and improved automation degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Such as Figure 4 As shown, the filter mechanism 12 in this embodiment is vertically arranged in the filter container 11, the rotary joint 122 is arranged at the bottom of the filter mechanism 12, and the self-cleaning mechanism is arranged on the side wall of the filter container. This structure effectively uses water pressure and gravity to flush the filter screen, and the filter screen is cleaned more cleanly.

Embodiment 2

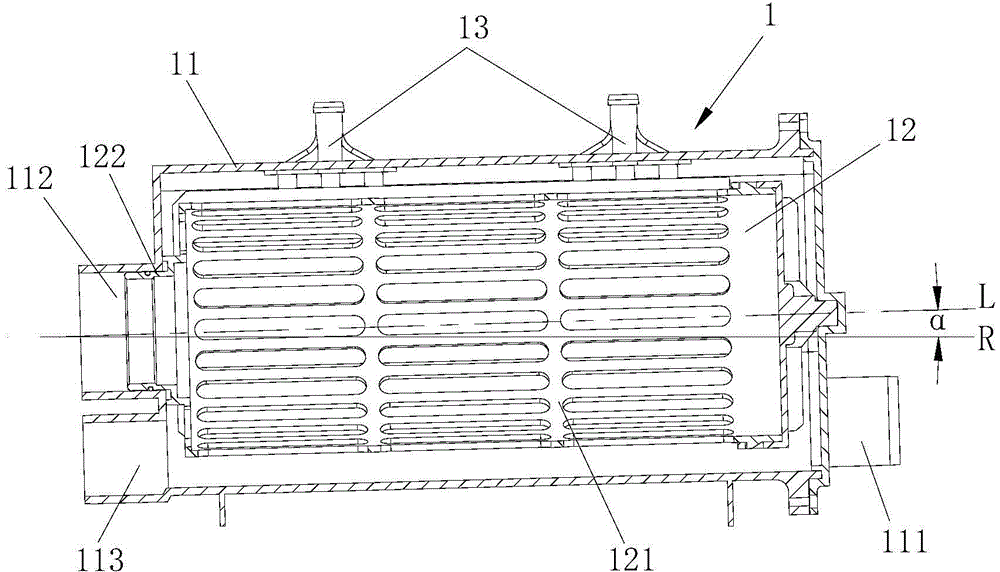

[0048] Such as figure 2 with image 3 As shown, the difference between this embodiment and the above-mentioned first embodiment is that: the axial direction L of the filter mechanism 12 rotates and the horizontal plane R has an inclined angle α, 0 ≤ α ≤ 30°, preferably 1° ≤ α ≤ 10 °, preferably 1°≤α≤3°, the rotary joint 122 is located at the lower end of the filter mechanism 12; by tilting or horizontally placing the filter mechanism, not only the filtering area can be increased, the filtering speed can be accelerated, but also the filter screen can be cleaned .

[0049] The structure can be realized in the following ways: 1. The filter container is arranged horizontally, and the filter mechanism is arranged obliquely; 2. The filter container and the filter mechanism are arranged obliquely together, and a support base is provided below the filter container.

[0050] Compared with the vertical arrangement of the filter mechanism in Embodiment 1, the advantages of the filter mec

Embodiment 3

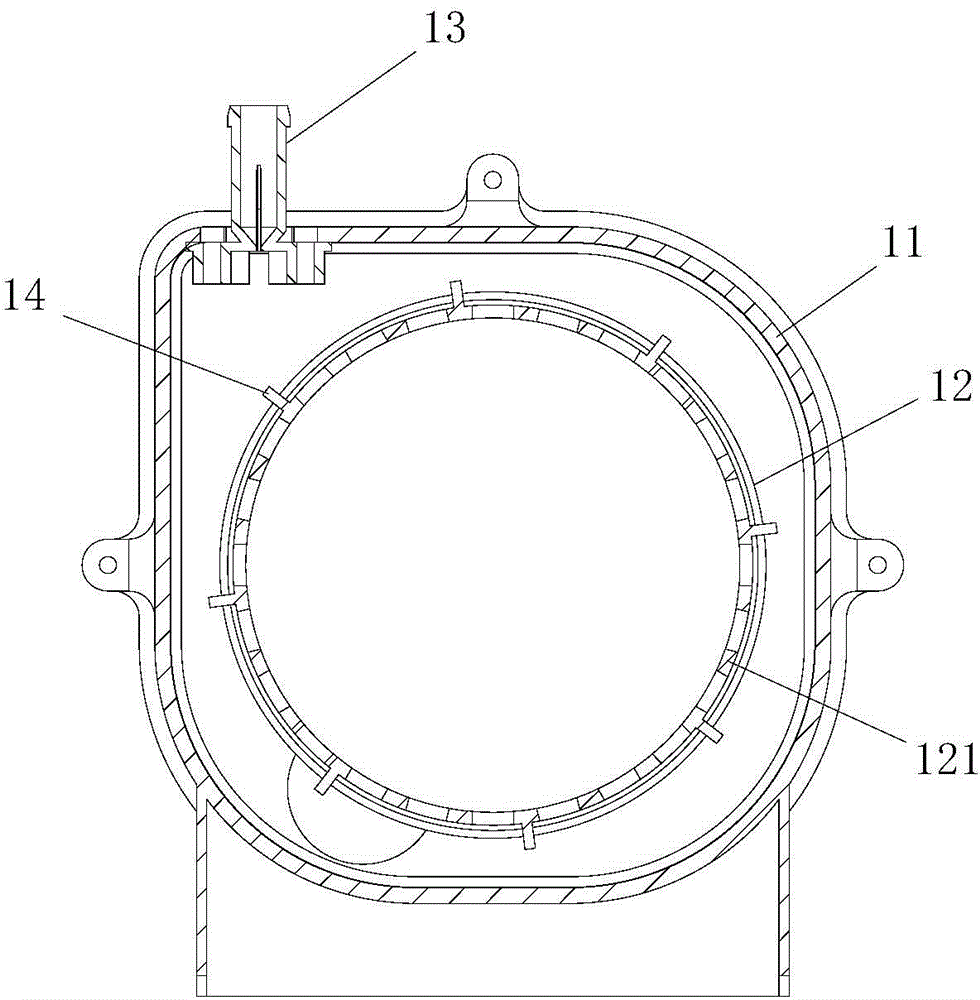

[0052] Such as Figure 4 As shown, the spray head 13 described in this embodiment is a tubular structure with one end closed and the other end connected to the cleaning water. The peripheral wall of the spray head 13 is provided with at least one water spray port 130 along the axial direction. The shape of the water spout 130 is circular, elliptical, strip-shaped, etc. The length of the nozzle should ensure that the width of the sprayed water flow is enough to cover the axial length range of the entire filter screen.

[0053] The tubular nozzle 13 can be provided in multiples, distributed on the side wall of the filter container 11, and arranged parallel to the rotation axis of the filter mechanism 12.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap