Bending device with functions of pressure detection and torque adjustment as well as method

A torque adjustment and bending device technology, applied in the field of sheet metal processing, can solve the problems of low sheet processing quality, real-time adjustment of sheet thickness, excessive bending, etc., to avoid excessive deformation and loose defects, and facilitate height and angle adjustment , Improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

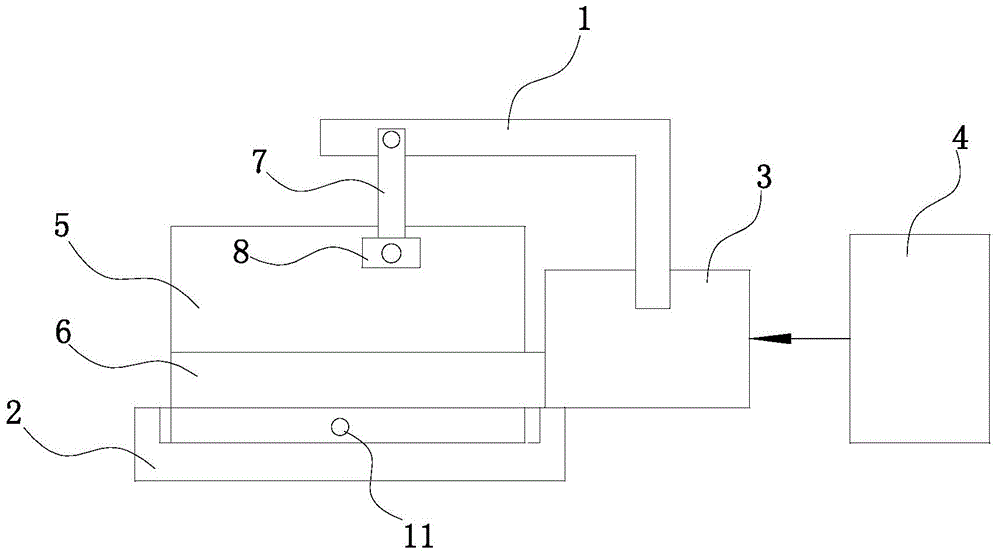

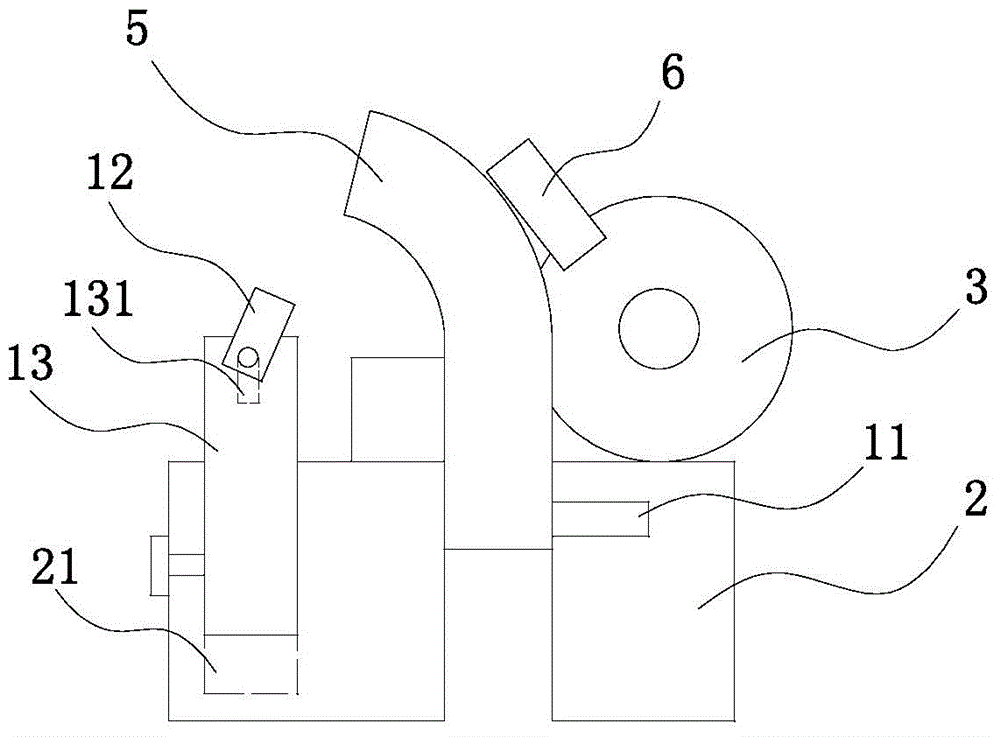

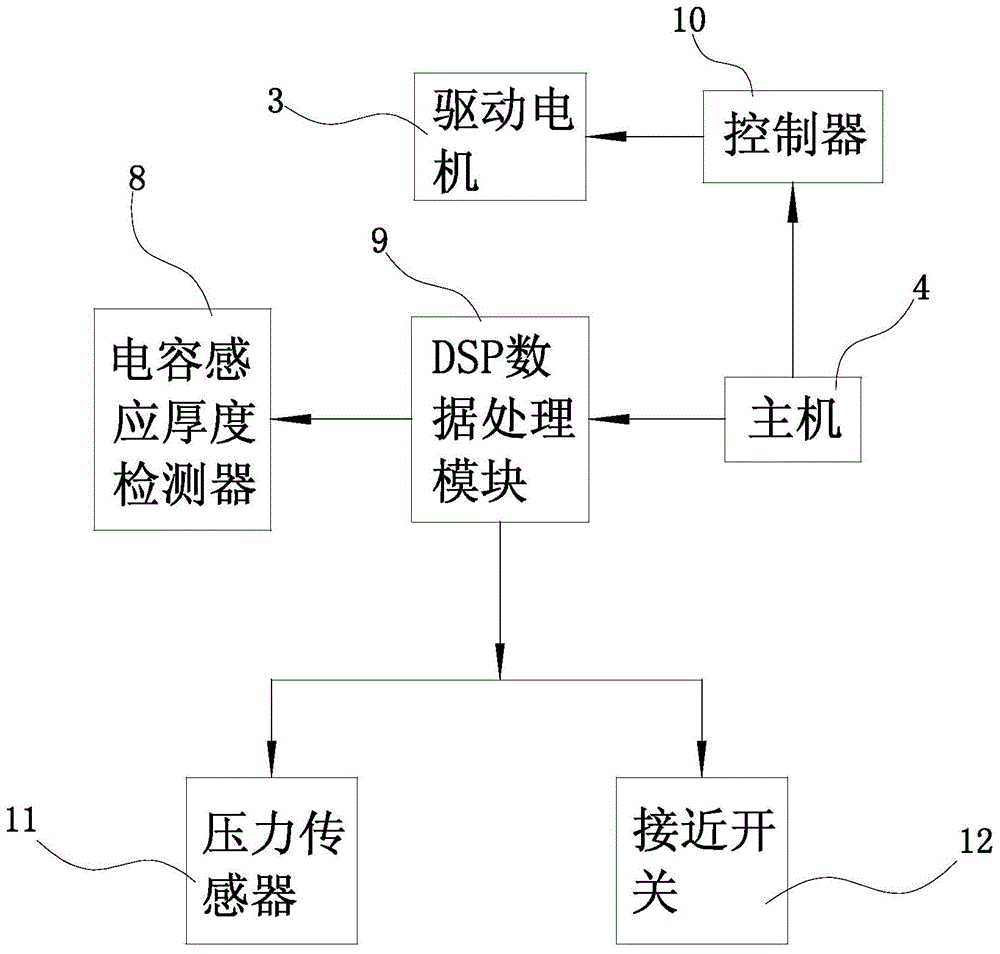

[0022] like figure 1 , figure 2 and image 3 As shown, the bending device with pressure detection and torque adjustment in this embodiment includes a drive motor 3 installed on the frame 1, a clamping and fixing seat 2, a host 4 for controlling the drive motor 3, and a motor shaft of the drive motor 3. The bending shaft 6 is installed on the top, the workpiece 5 is installed on the clamping and fixing base 2, and the capacitance induction thickness detector 8 installed on the frame 1 by means of the bracket 7, the support rod 13 installed on the clamping and fixing base 2 and the The pressure sensor 11, the controller 10 connected with the host machine 4, the support rod 13 is installed in the clamping groove 21 of the clamping seat 2, the upper end of the support rod 13 is connected to the proximity switch 12, and the pressure sensor 11 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap