Full-automatic stream inoculation machine

A flow inoculation, fully automatic technology, applied in the field of casting and pouring, can solve the problems of low yield, low quality of castings, inaccurate weighing of inoculants, etc., and achieve the effect of high yield and high quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

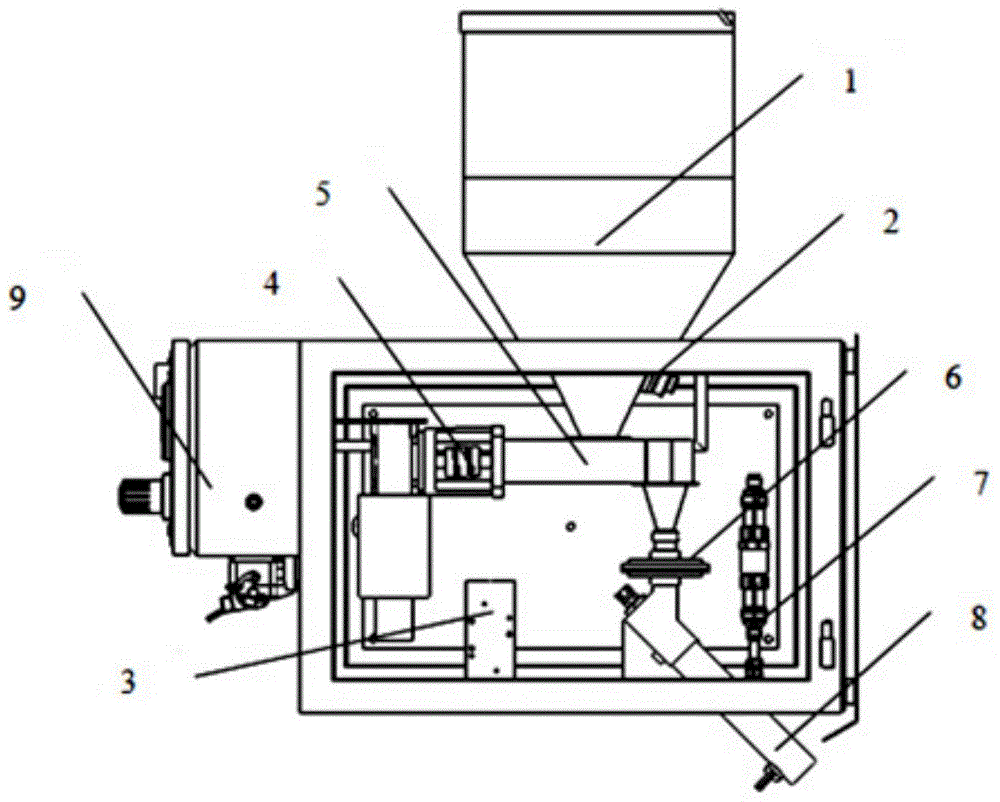

[0023] See figure 1 , The automatic flow-following inoculation machine of the present invention includes: 1, hopper, 2, material level sensor, 3, motor drive module, 4, coupling, 5, screw feed rod, 6, photoelectric sensor, 7, pressure sensor, 8. Discharge pipe, 9. Control cabinet. The hopper 1 is located above the material level sensor 2, the motor drive module 3 is located below the coupling 4, and the coupling 4 is located on the left side of the screw feed rod 5 and is connected to it, The screw feed rod 5 is located above the photoelectric sensor 6, the photoelectric sensor 6 is located above the discharge pipe 8, the pressure sensor 7 is located inside the discharge pipe 8, and the discharge pipe 8 is located Below the pressure sensor 6, the control cabinet 9 is located on the left side of the hopper 1.

[0024] The hopper 1 is used for inoculant;

[0025] The material level sensor 2 is used to detect the amount of inoculant in the hopper, if the material level is low, it will

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap