Lubricating structure for output shaft of liquid booster pump

A technology of lubricating structure and output shaft, applied in lubricating parts, engine lubrication, lubricating oil control valve, etc., can solve the problems of low hydraulic pressure, long crankshaft, unable to obtain good spray effect, etc., to achieve extended use Long life, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

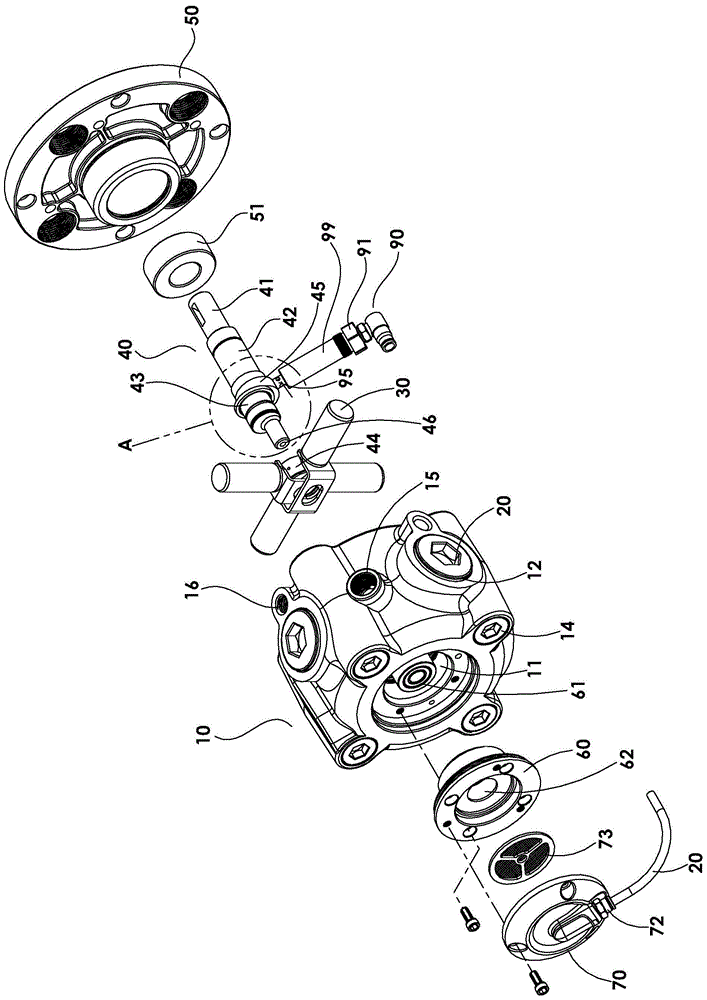

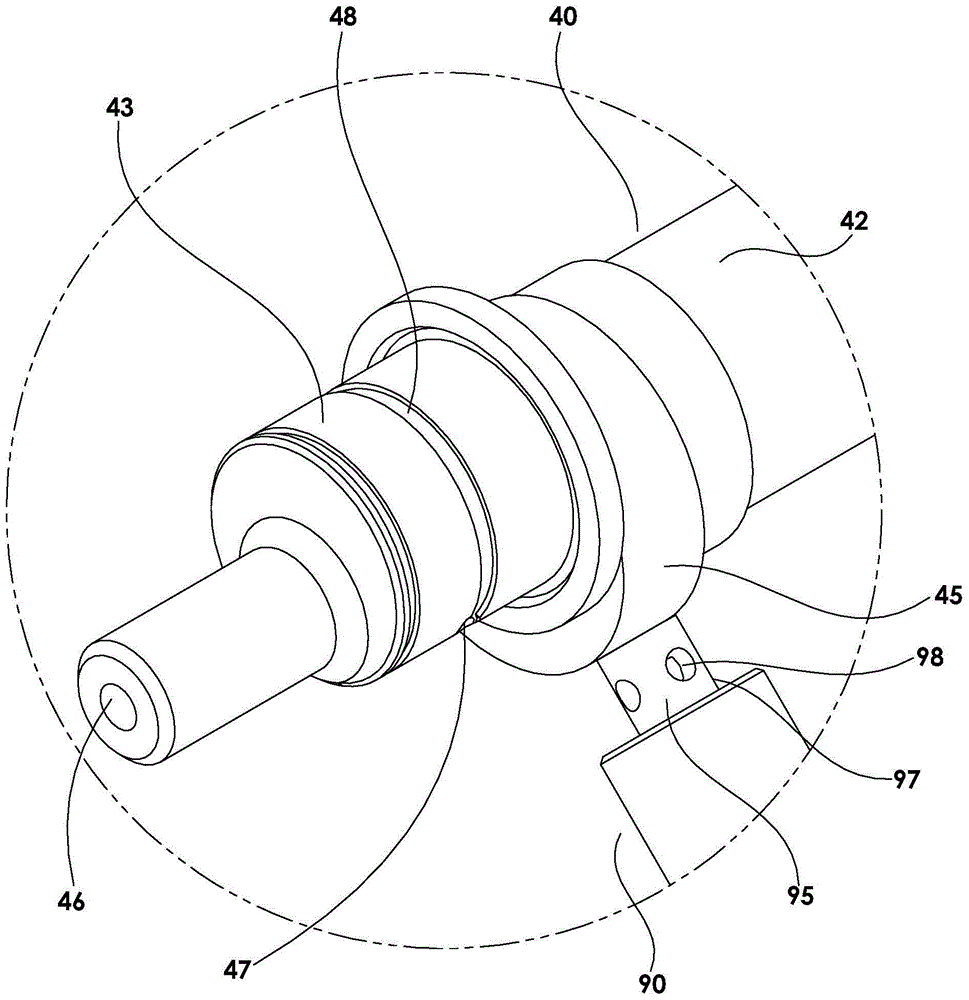

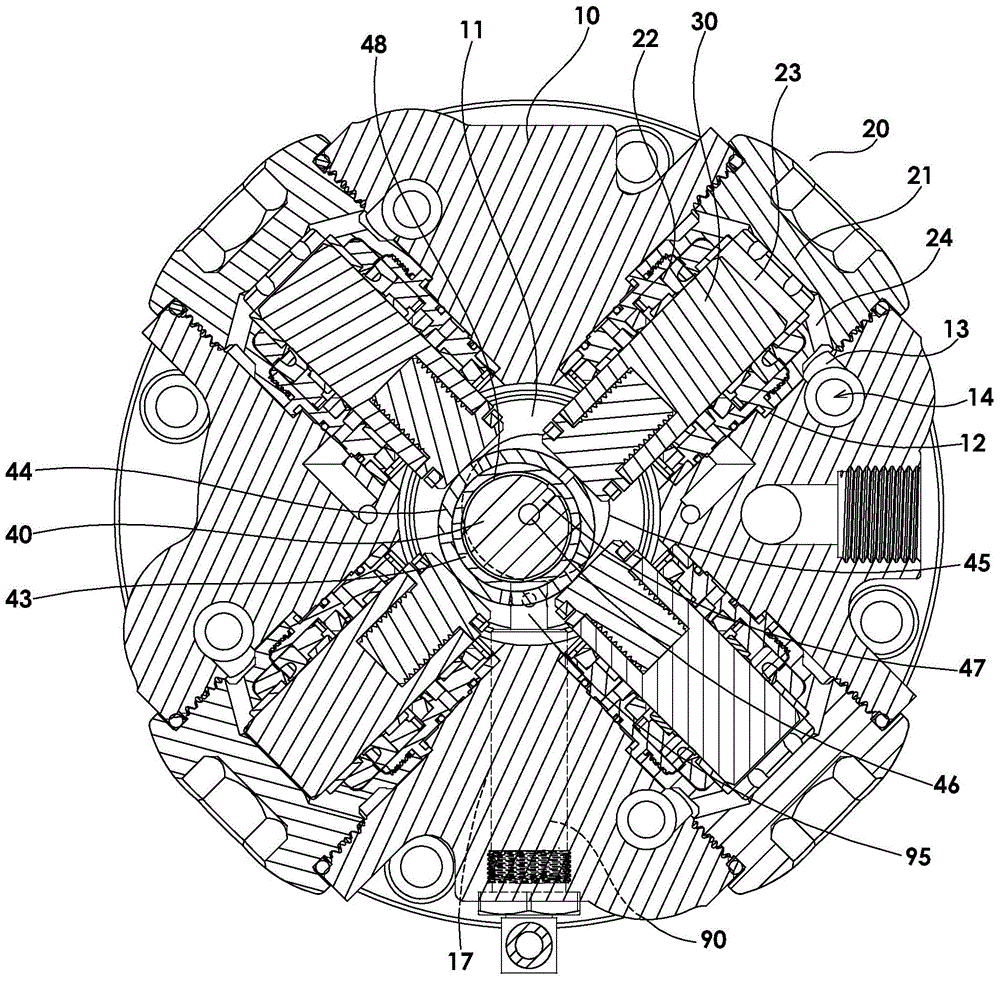

[0036] A liquid pressurized pump output shaft lubrication structure is a pump, such as figure 1 , 2 , 3, 4, 5, including a pump body 10, a plurality of plunger cap groups 20, a plurality of pillar plugs 30 and an output shaft 40; the pump body 10 has a circular core filled with lubricating oil as a mechanical chamber Holes 11, the radial direction of the core hole 11, a plurality of fixed holes 12 are arranged radially and evenly, and each fixed hole 12 is provided with a liquid inlet and outlet 13 in the radial direction, and each of the liquid inlets and outlets 13 is Each is communicated with a non-return valve group 14, and the liquid-inlet non-return end and the liquid-exit non-return end of each of the non-return valve groups 14 are respectively communicated with a liquid-in connection hole 15 and a liquid-out connection hole 16, so that the The liquid inlet and outlet 13 can pass through the liquid inlet check of the check valve group 14, and access the external liquid fr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap