Material conveying wheel assembly for pneumatic feeding mechanism

A technology of feeding mechanism and feeding wheel, which is applied in the field of mechanical processing, can solve the problems of increasing process difficulty and slow processing efficiency, and achieve the effect of simplifying and compacting the structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0019] (Example 1)

[0020] Figure 1 to Figure 2 A specific embodiment of the present invention is shown.

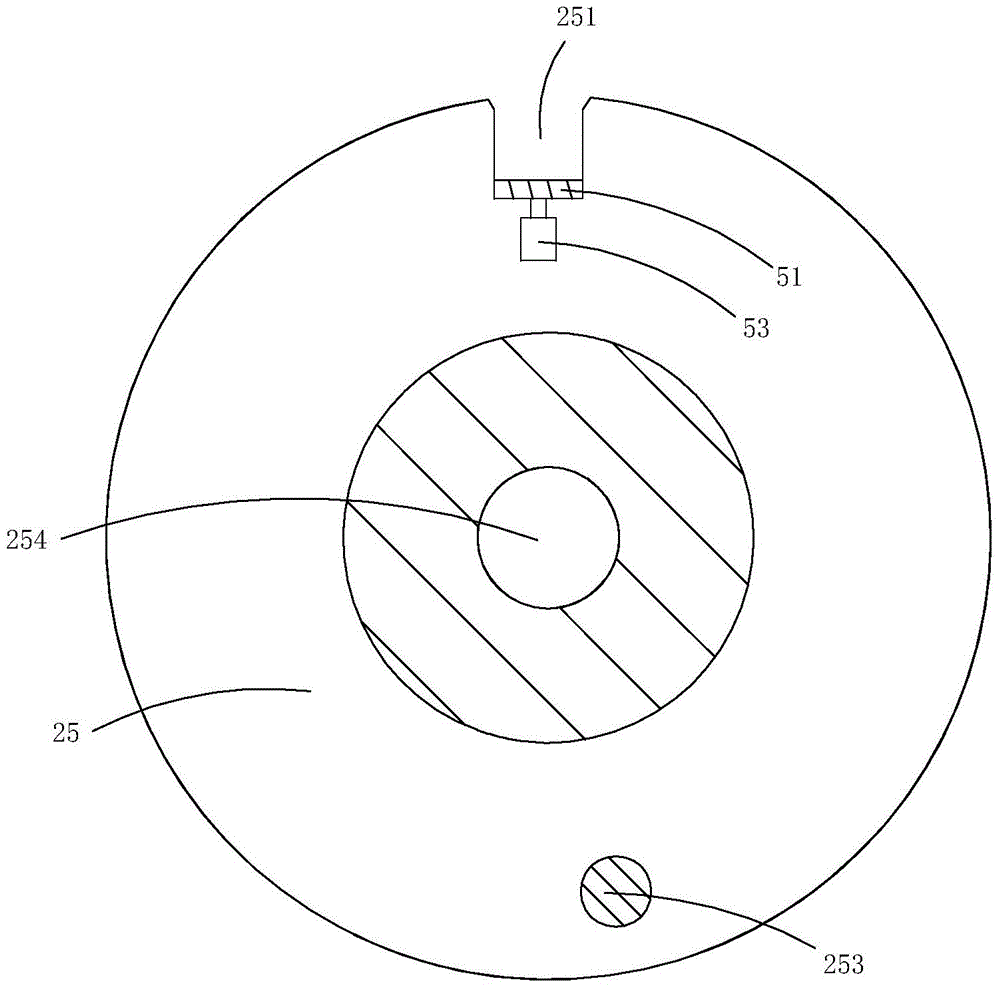

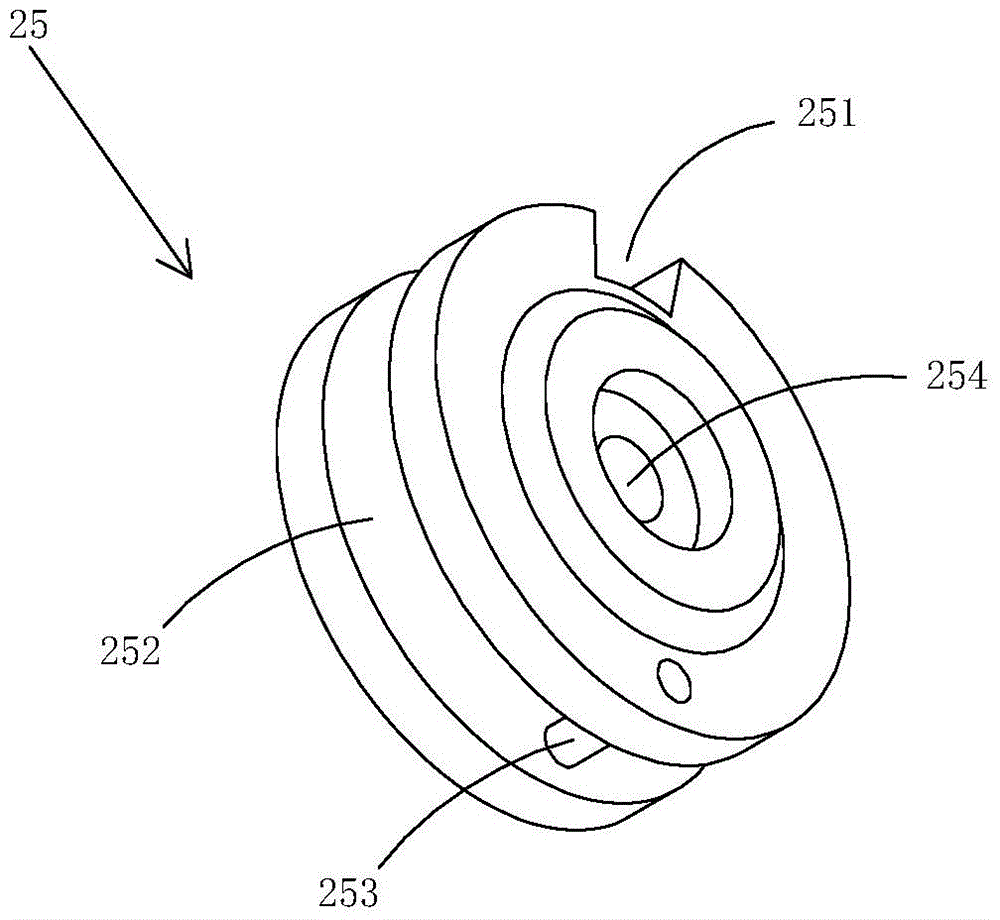

[0021] This embodiment is a transfer wheel assembly used in a pneumatic feeding mechanism, see Figure 1 to Figure 2 As shown, the material transfer wheel assembly includes a material transfer wheel 25 and a clamping cylinder 51 and a push block 52 arranged on the material transfer wheel.

[0022] A trough 251 is provided on the outer peripheral wall of the transfer wheel, and the extension direction of the trough is parallel to the direction of the central axis of rotation of the transfer wheel. The shape of the trough in this embodiment is U-shaped.

[0023] The center of the outer peripheral wall of the transfer wheel is also provided with an annular notch 252 along the circumferential direction, a pin 253 passing through the annular notch, and a central shaft hole 254. The central shaft hole is located at the center of the transfer wheel, and the pin is located outside the cen

Example

[0026] (Application example 1)

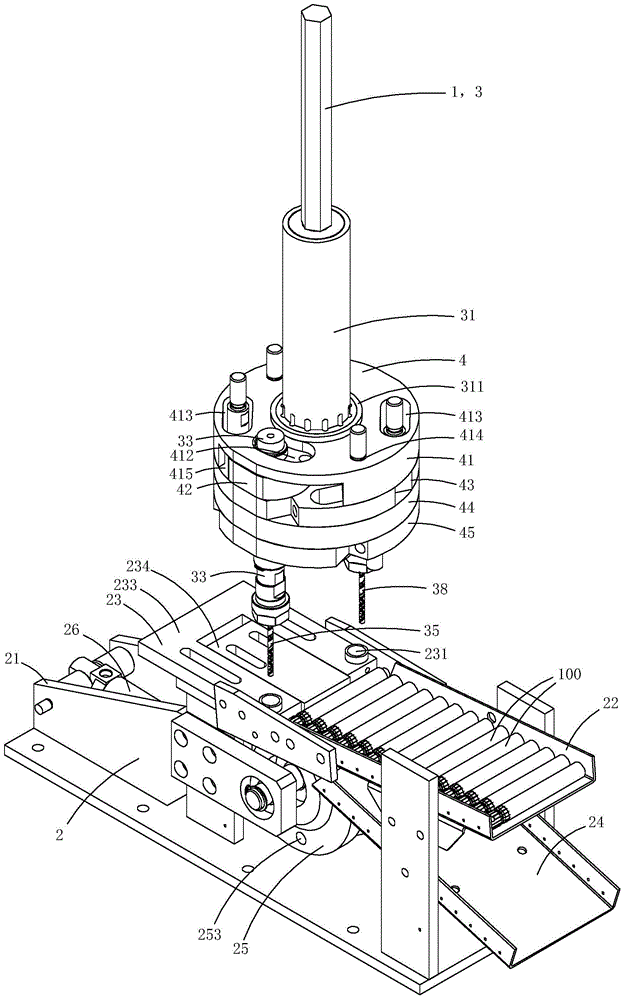

[0027] Figure 3 to Figure 12 A specific embodiment of the present invention is shown.

[0028] This embodiment is a pneumatic automatic feed type bench drill, see Figure 3 to Figure 12 As shown, the bench drill includes a bench drill body 1 and a feeding mechanism 2.

[0029] The bench drill body 1 includes a double drill mechanism 3 and a lifting mechanism (not shown in the figure) for driving the double drill mechanism 3 to move up and down.

[0030] The double drill mechanism 3 includes a mounting disk 4, a main shaft 31 rotatably arranged at the center of the mounting disk, a driving wheel 32 fixed on the main shaft, a first transmission shaft 33 rotatably disposed on the mounting disk, and a first transmission shaft fixedly disposed on the upper end of the first transmission shaft. The first driven wheel 34, the first drill bit 35 arranged at the lower end of the first transmission shaft, the second transmission shaft 36 rotatably arranged on the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap