Hydraulic embedded type watertight and fireproof hatch cover

A buried, hatch cover technology, applied in the direction of ship hatches/hatch, ship parts, transportation and packaging, etc., can solve the problems of large installation position, complex mechanical structure, and large overall volume of the sealing door, etc. To achieve the effect of simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

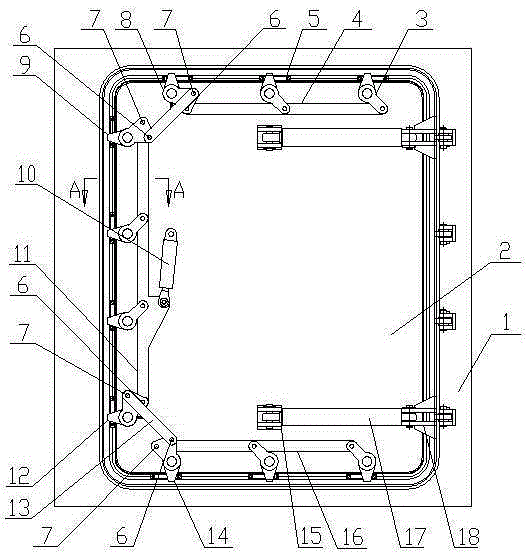

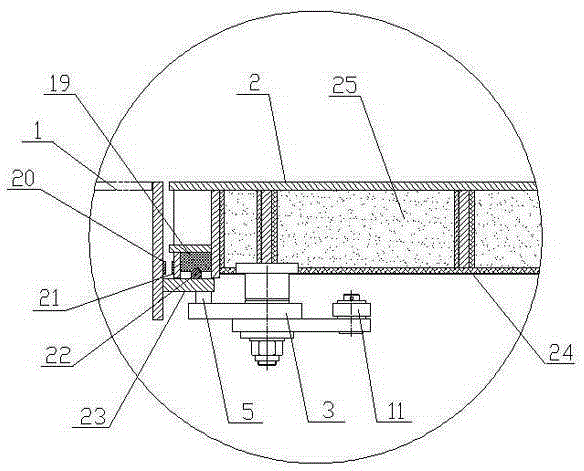

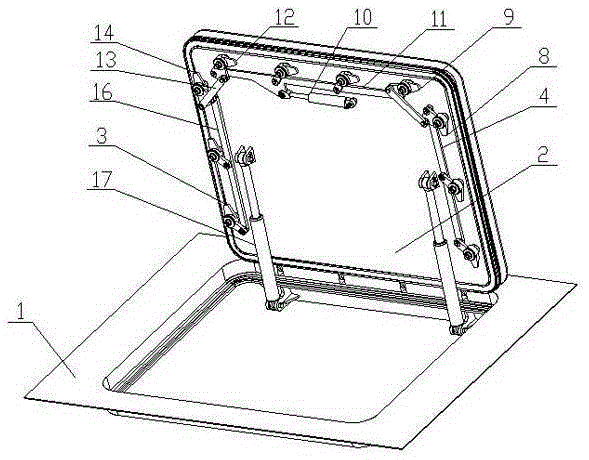

[0018] like figure 1 , figure 2 and image 3 As shown, the hydraulic embedded watertight fireproof hatch cover of the present invention includes a cover plate 2 which is hollow and filled with ceramic wool 25 . The inner surface of the cover plate 2 is made of an inorganic fireproof board 24 . There are shrouds 1 around the cover 2, and a set of corresponding sides of the shroud 1 and the cover 2 are hingedly fitted, and there is a locking mechanism between the shroud 1 and the cover 2. The locking mechanism includes a first connecting rod 4, a second connecting rod 11 and a third connecting rod 16 positioned on the inner side of the cover plate 2. The second connecting rod 11 is positioned on the inner side of the cover plate 2 away from the hinged side. The connecting rod 4 and the third connecting rod 16 are respectively located on the inner sides of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap