Pixel structure, manufacturing method for pixel structure, display panel and display apparatus

A pixel structure and display device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problem that the pixel structure cannot be compatible with ordinary display and virtual display at the same time, and achieve good visual matching effect and strong uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

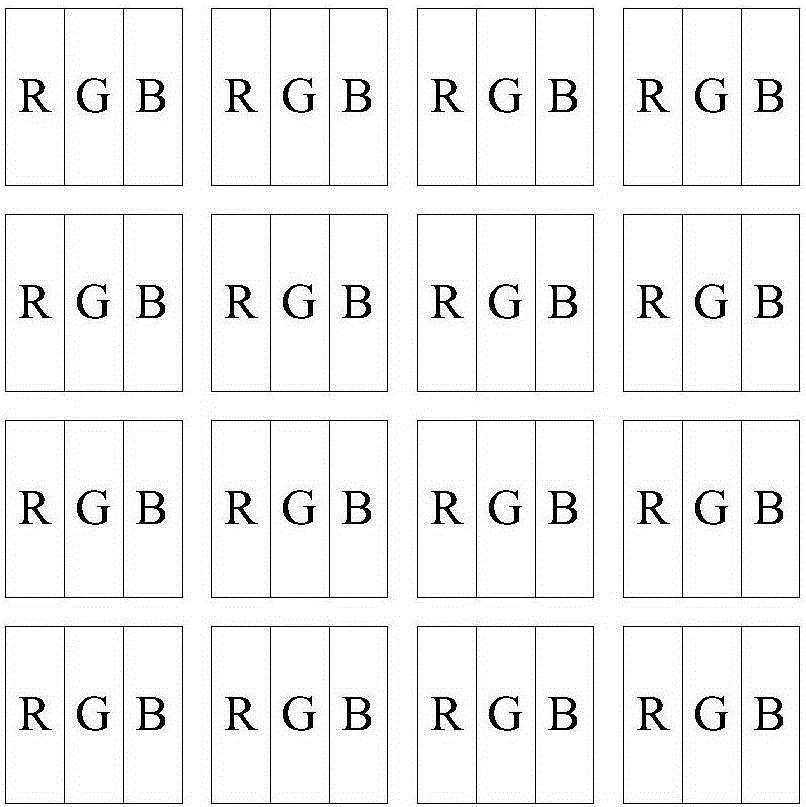

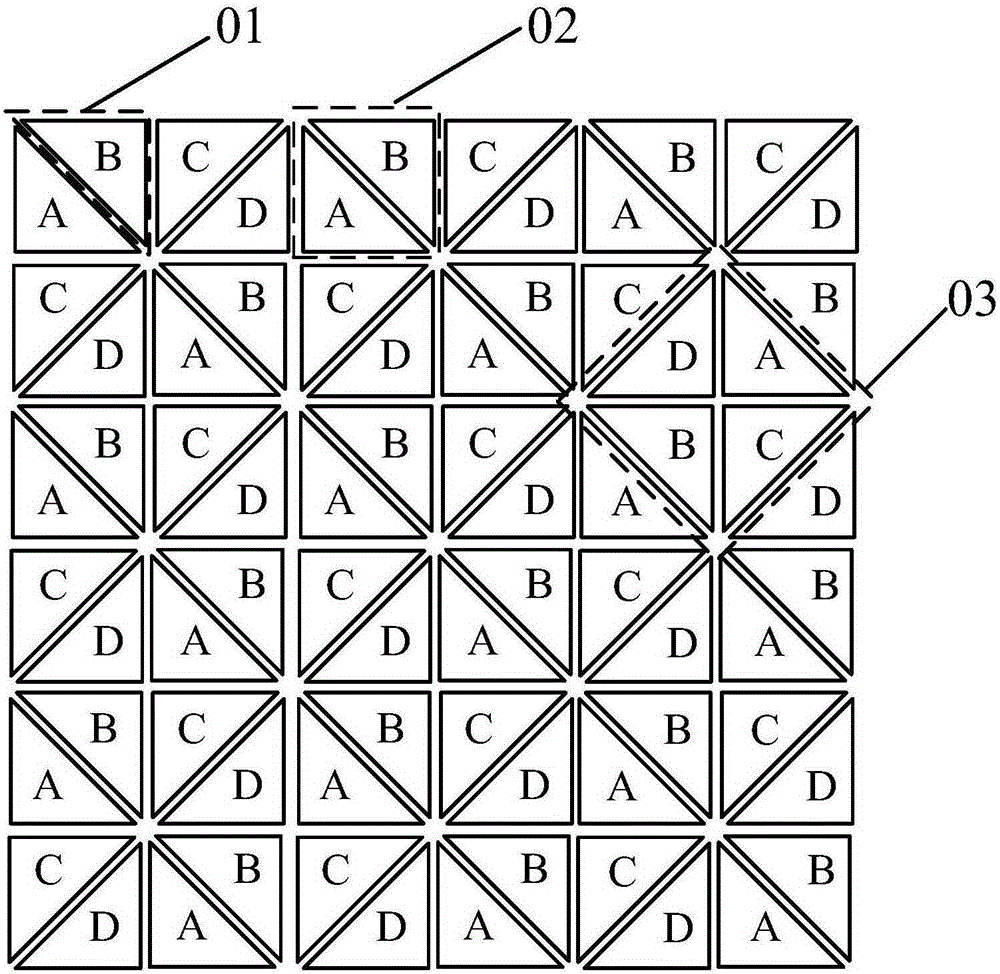

[0048] When the above-mentioned pixel structure provided by the embodiment of the present invention is arranged in a rectangular effective display area, a mask plate can be used to form color-resist patterns of sub-pixels of two colors in the pixel structure respectively. There are four sub-pixels of different colors in the pixel structure, therefore, all the color-resist patterns can be formed respectively by using two masks. Its specific implementation is as follows:

[0049] Firstly, using the first mask plate to form the color-resist pattern of the sub-pixels of the first color in the pixel structure;

[0050] Then, using the first mask rotated by 180 degrees to form the color-resist pattern of the sub-pixels of the second color in the pixel structure;

[0051] Next, using a second mask to form a color-resist pattern for the sub-pixels of the third color in the pixel structure;

[0052] Finally, the color resist pattern of the fourth color sub-pixel in the pixel structure i

Embodiment 2

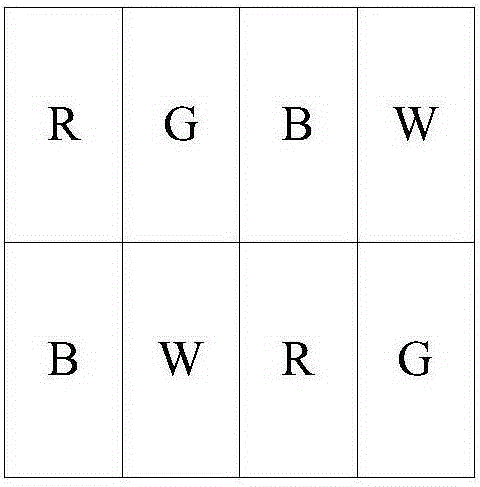

[0059] When the above-mentioned pixel structure provided by the embodiment of the present invention is set in a square effective display area, a mask plate is used to respectively form the color resistance patterns of three or four color sub-pixels in the pixel structure, wherein, a mask is used The case where the plate forms the color-resist patterns of the three-color sub-pixels in the pixel structure is the case where the color-resist patterns of the white sub-pixels do not need to be patterned. There are four sub-pixels of different colors in the pixel structure. Therefore, a mask plate is used to rotate the mask plate by 90 degrees on the basis of the previous color-resist pattern composition through the composition of each color-resist pattern. All the color resist patterns can be formed separately.

[0060] When it is necessary to make color-resisting patterns of four colors, the specific implementation method is as follows:

[0061] Firstly, using the first mask plate to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap