Excavator moving arm body locating component

A technology for positioning components and mobile arms, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low processing and production efficiency, troublesome machining procedures, and low welding production efficiency, and achieve improved assembly and welding Quality, easy installation and use, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

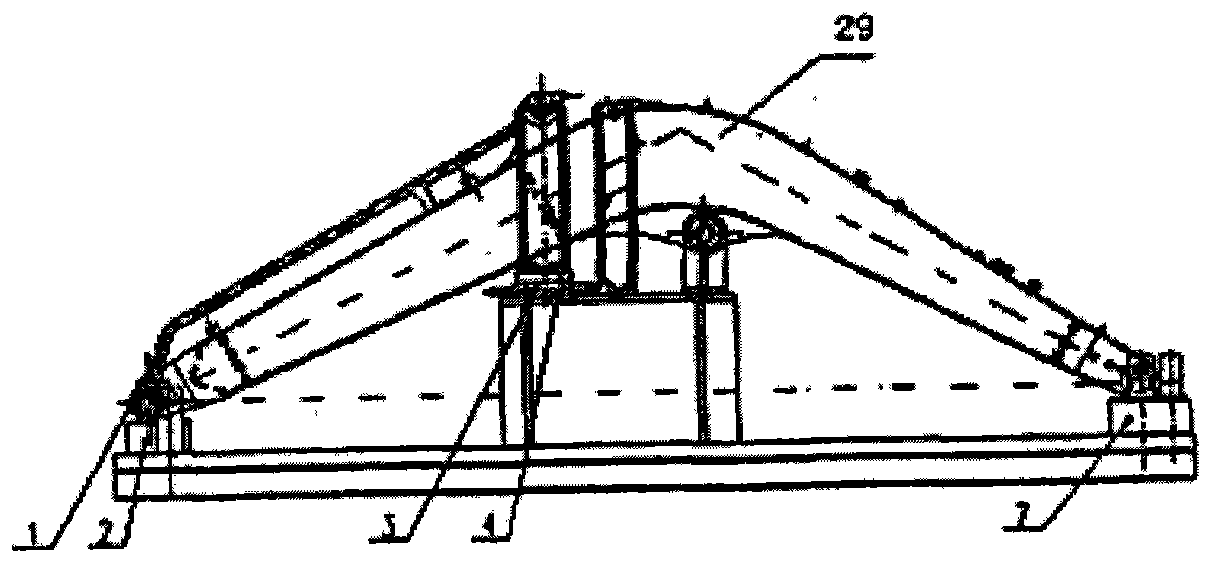

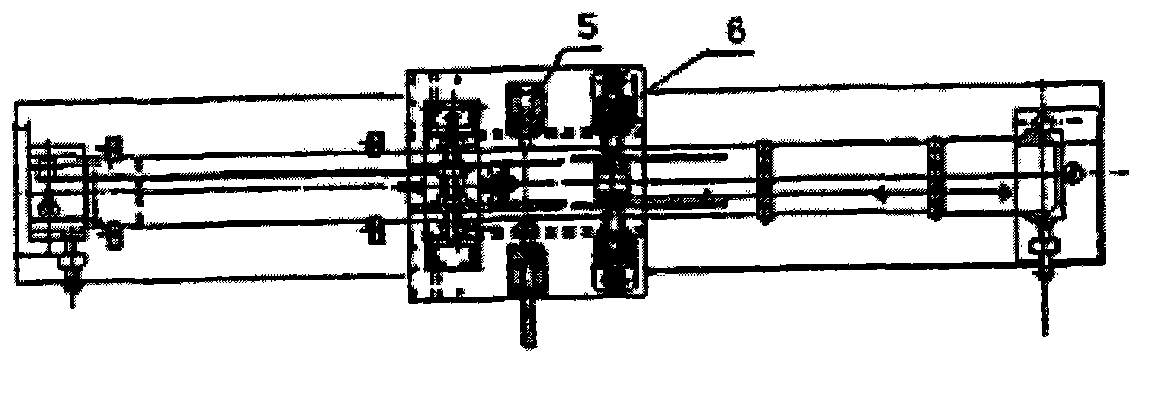

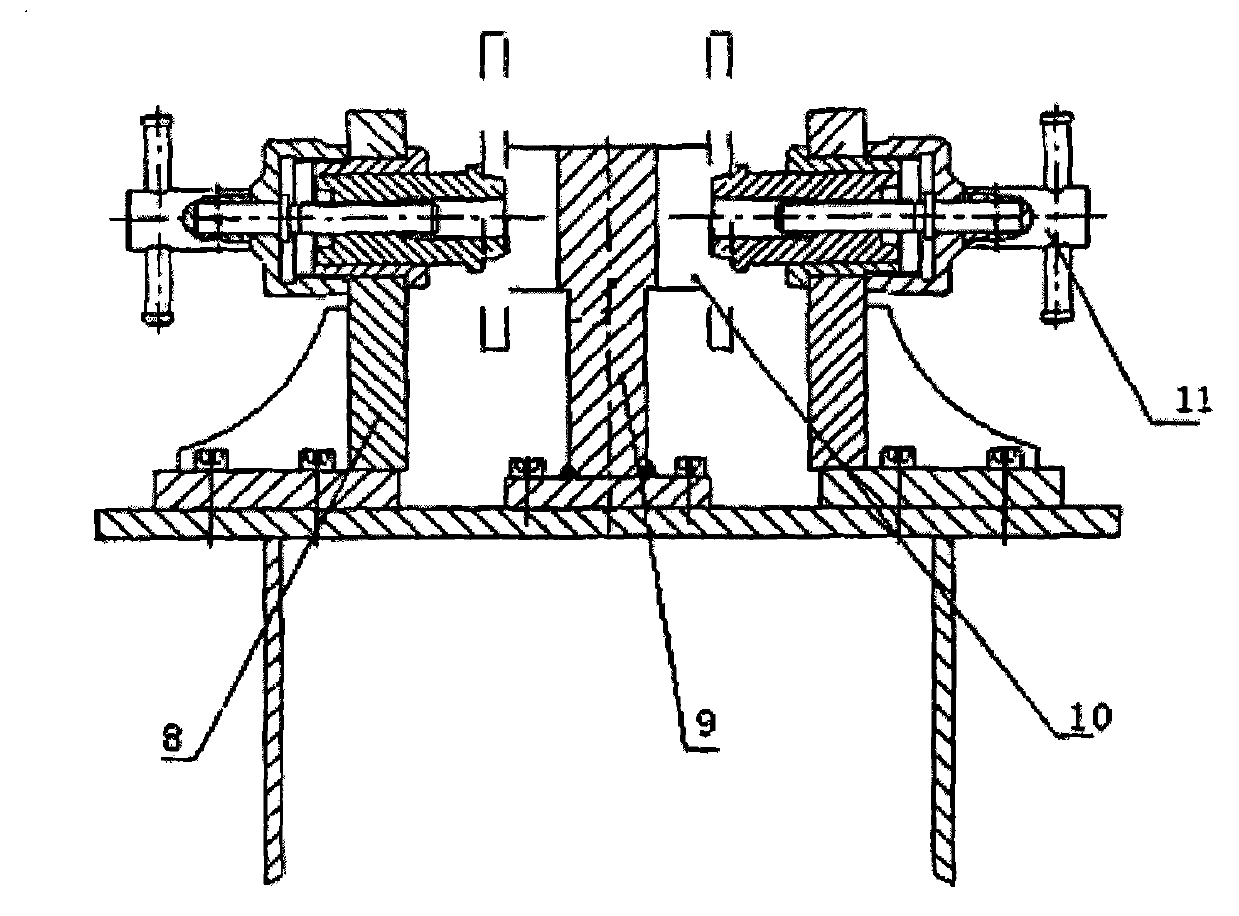

[0028] Below in conjunction with accompanying drawing, the present invention will be further described, there are upper support plate adjustment mechanism (3), upper support plate positioning assembly (4), side positioning support (5), lower support plate at the convex bend in the middle of boom body (29) The positioning assembly (6) is supported and fastened, and the end of the boom body (29) with the outer diameter of the cylinder is supported on the rear end of the positioning assembly (7), and the end with the measuring rod assembly (1) on the other side is supported on the front end. The positioning assembly (2) has formed three-point positioning like this, so that the workpiece has stability. The last support plate positioning seat (28) is contained in the front top of the boom body (29). In the positioning assembly (6) of the lower support plate, the positioning screw assembly (8) is clamped in the ear plate assembly (7) of the boom body (7), and the outer diameter of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap