Germanium tetrachloride bubbling-tank device and bubbling method of germanium tetrachloride

A germanium tetrachloride and bubbling technology, which is applied to the bubbling tank device of germanium tetrachloride and the bubbling field of germanium tetrachloride, can solve the problems affecting the amount of raw materials carried and the uniformity of products, etc., to reduce Energy consumption, effect of homogenization of preparation parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

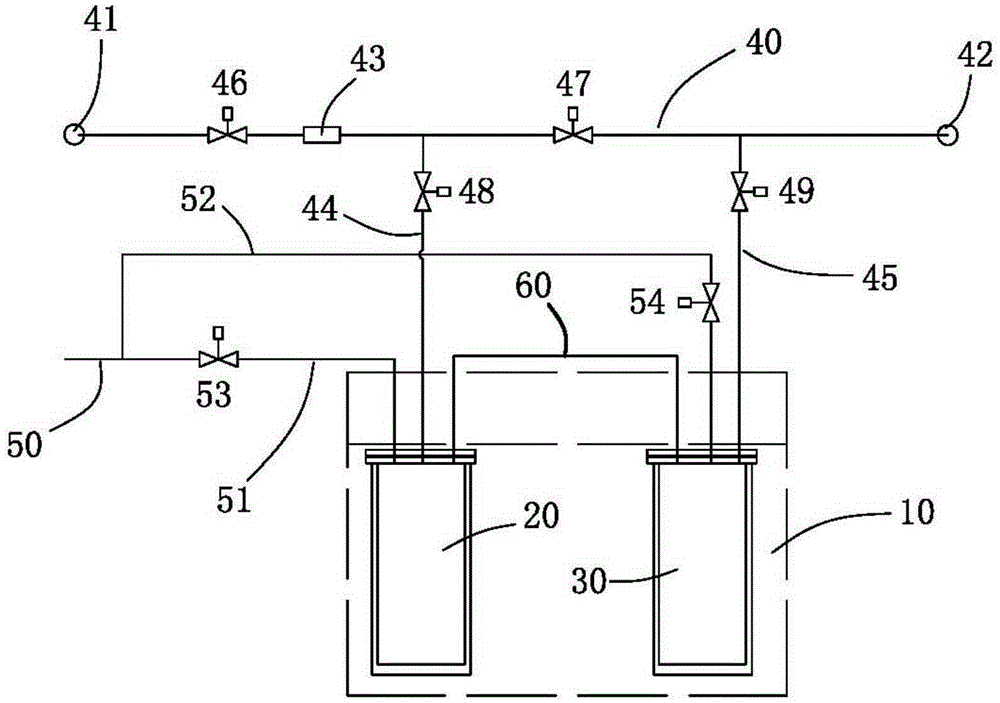

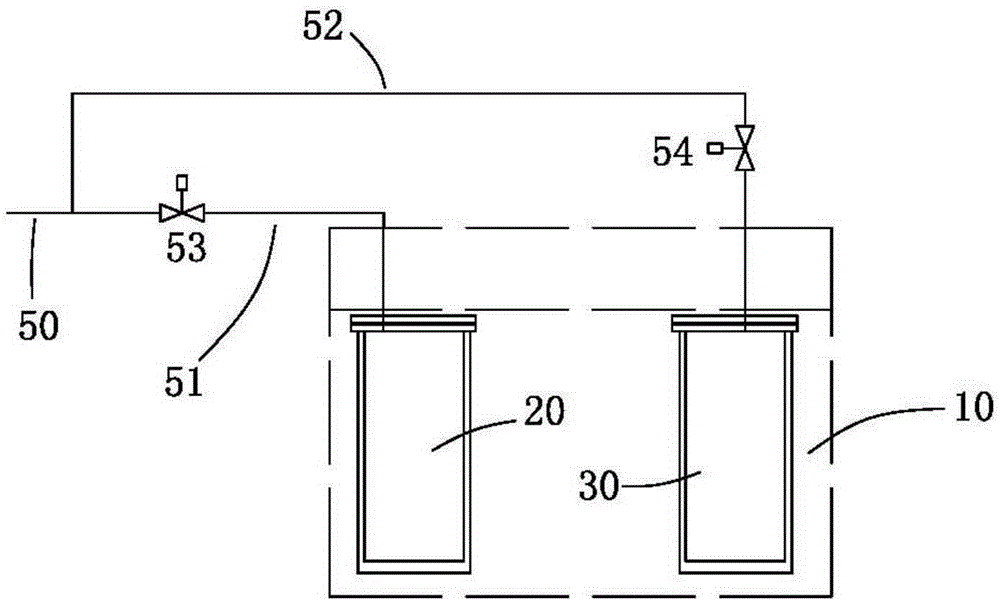

[0042] The invention discloses a germanium tetrachloride bubbling tank device. The bubbling tank device adopts double tanks of carrier gas to bubble germanium tetrachloride, such as figure 1 As shown, the bubble tank device includes: a water bath system, the water bath system is provided with a water tank 10, the first bubble tank 20 and the second bubble tank 30 are installed in the water bath system, and the first bubble tank 20 and the second bubble tank are installed in the water bath system. The connection pipe 60 between the two bubble tanks 30, the gas inlet pipe 40, and the germanium tetrachloride inlet pipe 50. Wherein, the first bubble tank 20 and the second bubble tank 30 have the same structure and are arranged side by side in the water tank 10, the first bubble tank 20 and the second bubble tank 30 are made of transparent quartz glass, and are used for Liquid germanium tetrachloride.

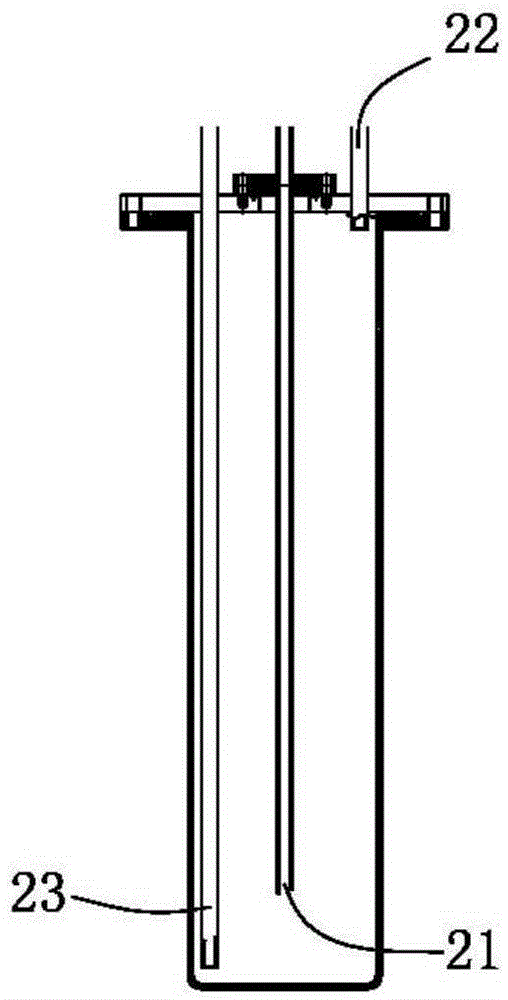

[0043] The internal materials of the first bubbler tank 20 and the second bubbler

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap