Passing through type steel pipe magnetic leakage detection air flotation detection boot

A through-type, steel pipe technology, applied in the direction of material magnetic variables, etc., can solve the problems of increasing the production cost of the probe shoe and installation workload, and the inability to detect the steel pipe area, etc., achieve a good working environment temperature, avoid direct heat conduction, and improve flaw detection Effects of Accuracy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

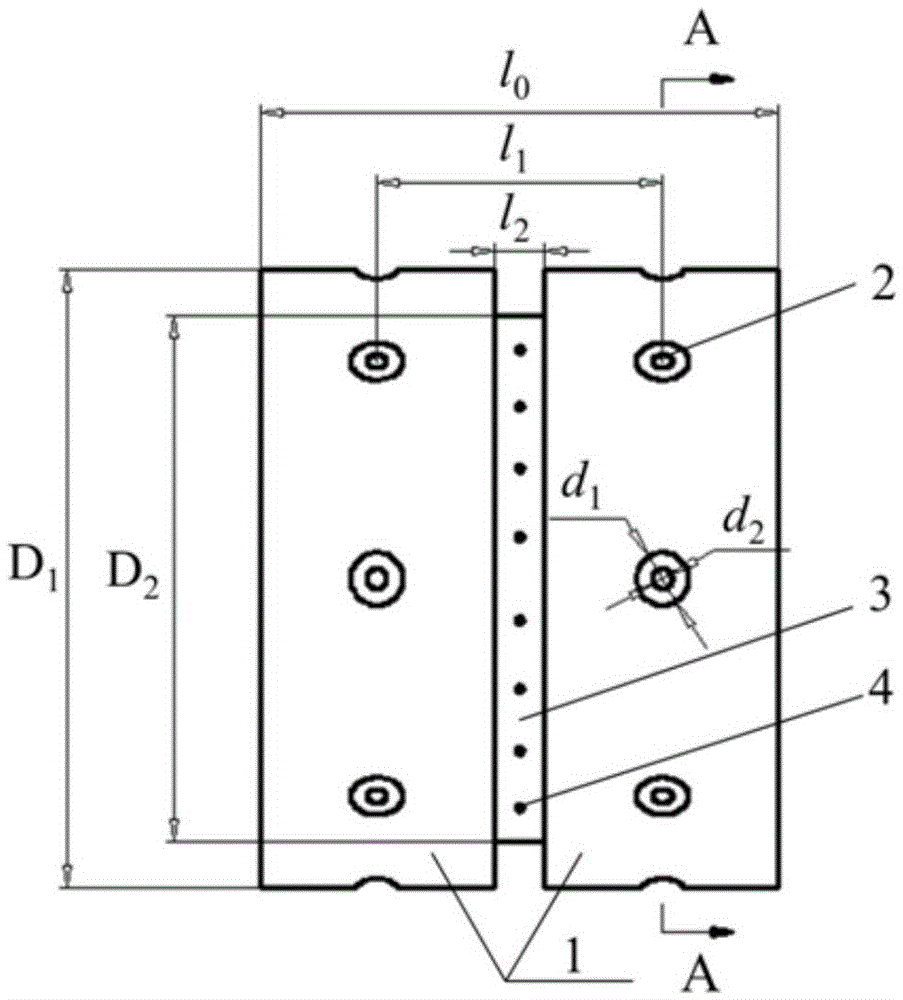

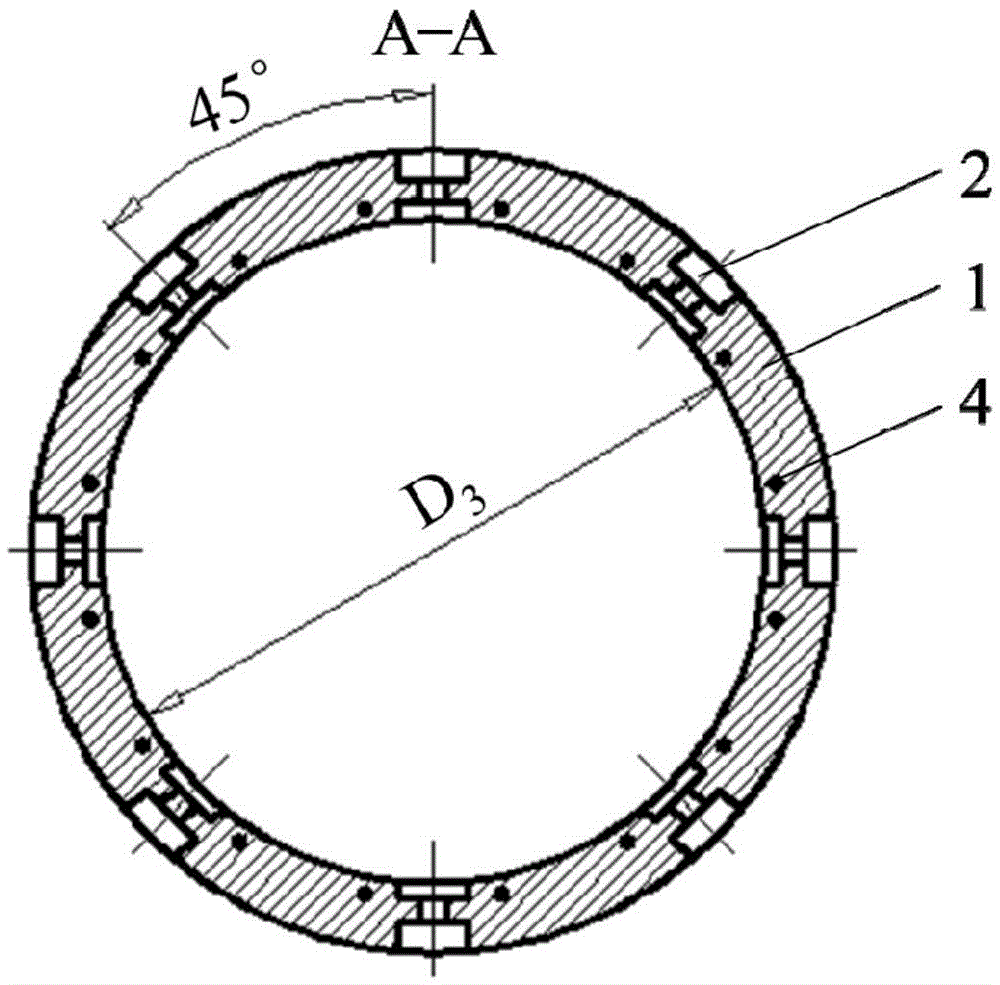

[0036] The through-type steel pipe magnetic flux leakage flaw detection air flotation probe described in this embodiment is as follows: figure 1 , figure 2 As shown, it includes a sensor 4 and a cylindrical body 1 with open structures at both ends. The cylindrical body 1 is made of aluminum alloy, and the inner diameter D of the cylindrical body is 3 =d+2h 1 , outer diameter D 1 =D 3 +20mm (that is, the wall thickness is 10mm), length l 0 is 200mm, where d is the outer diameter of the steel pipe to be tested, h 1 is the distance between the inner wall of the cylindrical body and the outer wall of the steel pipe to be detected when the steel pipe to be detected is located in the inner hole of the cylindrical body and is coaxial with the cylindrical body, h 1 = 0.1mm, D 3 is the inner diameter of the cylindrical body, D 1 is the outer diameter of the cylindrical body; the wall of the cylindrical body is provided with two circles of throttling holes 2 for inputting pressur

Embodiment 2

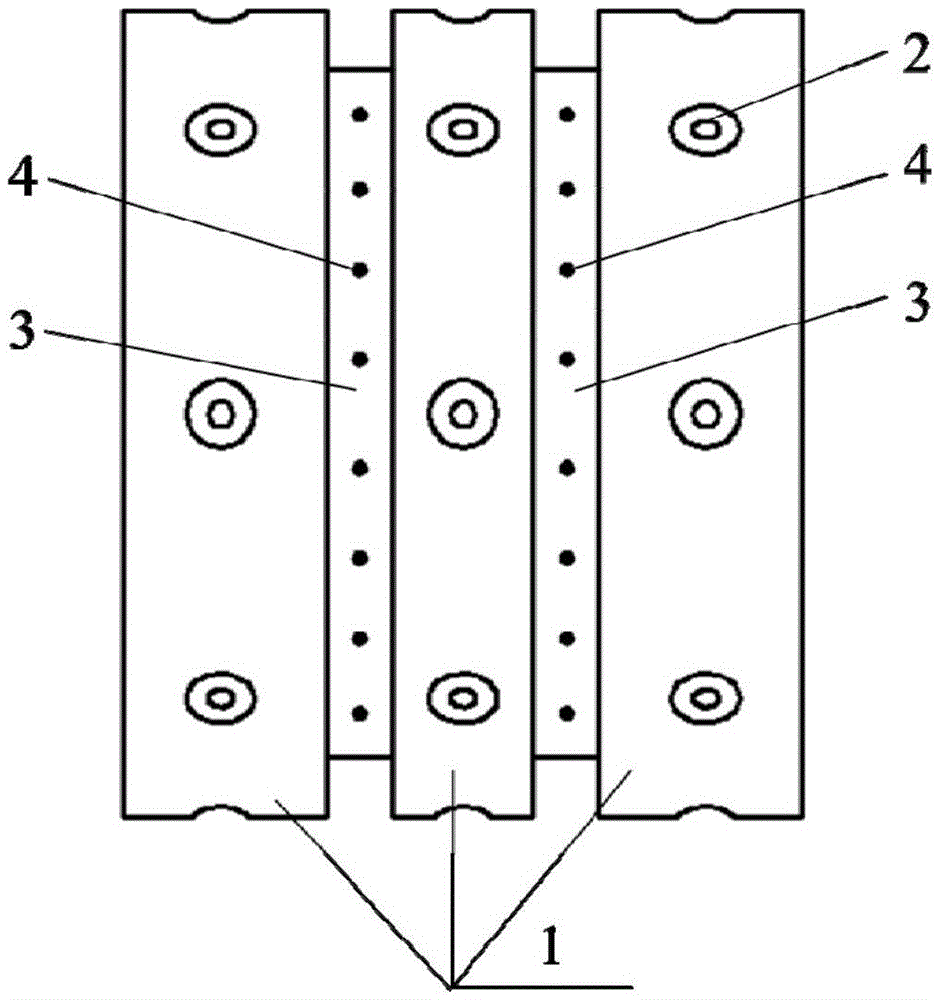

[0038] The through-type steel pipe magnetic flux leakage flaw detection air flotation probe described in this embodiment is as follows: image 3 Shown, and embodiment 1 difference is: 1, the length l of cylindrical body 1 0 is 300mm, when the steel pipe to be detected is located in the inner hole of the cylindrical body and is coaxial with the cylindrical body, the distance h between the inner wall of the cylindrical body and the outer wall of the steel pipe to be detected 1 =0.5mm; 2. There are three circles of throttle holes 2 for inputting pressure air into the inner hole of the cylindrical body and two circles of annular grooves 3 for installing sensors on the wall of the cylindrical body, two adjacent circles The spacing between the orifices is the same as l 1 3. The number of throttle holes in the three circles of throttle holes is six, and the diameter of the middle part of the throttle hole is d 2 =1.2mm, the hole diameter of air inlet and air outlet d 1 =6mm; 4. The w

Embodiment 3

[0040] The through-type steel pipe magnetic flux leakage flaw detection air flotation probe described in this embodiment is as follows: Figure 4 Shown, and embodiment 1 difference is: 1, the length l of cylindrical body 1 0 is 260mm, when the steel pipe to be detected is located in the inner hole of the cylindrical body and is coaxial with the cylindrical body, the distance h between the inner wall of the cylindrical body and the outer wall of the steel pipe to be detected 1 =0.3mm; 2. There are 12 throttle holes in the two circles of throttle holes, and the diameter of the middle part of the throttle hole is d 2 =0.8mm, the hole diameter of air inlet and air outlet d 1 = 4mm; 3. A circle of annular groove 3 arranged on the cylinder wall of the cylindrical body is located between the left ring throttle hole and the left end surface of the cylindrical body, and the gap between the left groove wall of the annular groove and the left end surface of the cylindrical body The spacin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap