Filter with self-cleaning filtration plate

A filter plate and filter technology, applied in the direction of filtration separation, filtration loop, separation method, etc., can solve the problems of loss of filtration effect of the filter, low product quality, incomplete filtration, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

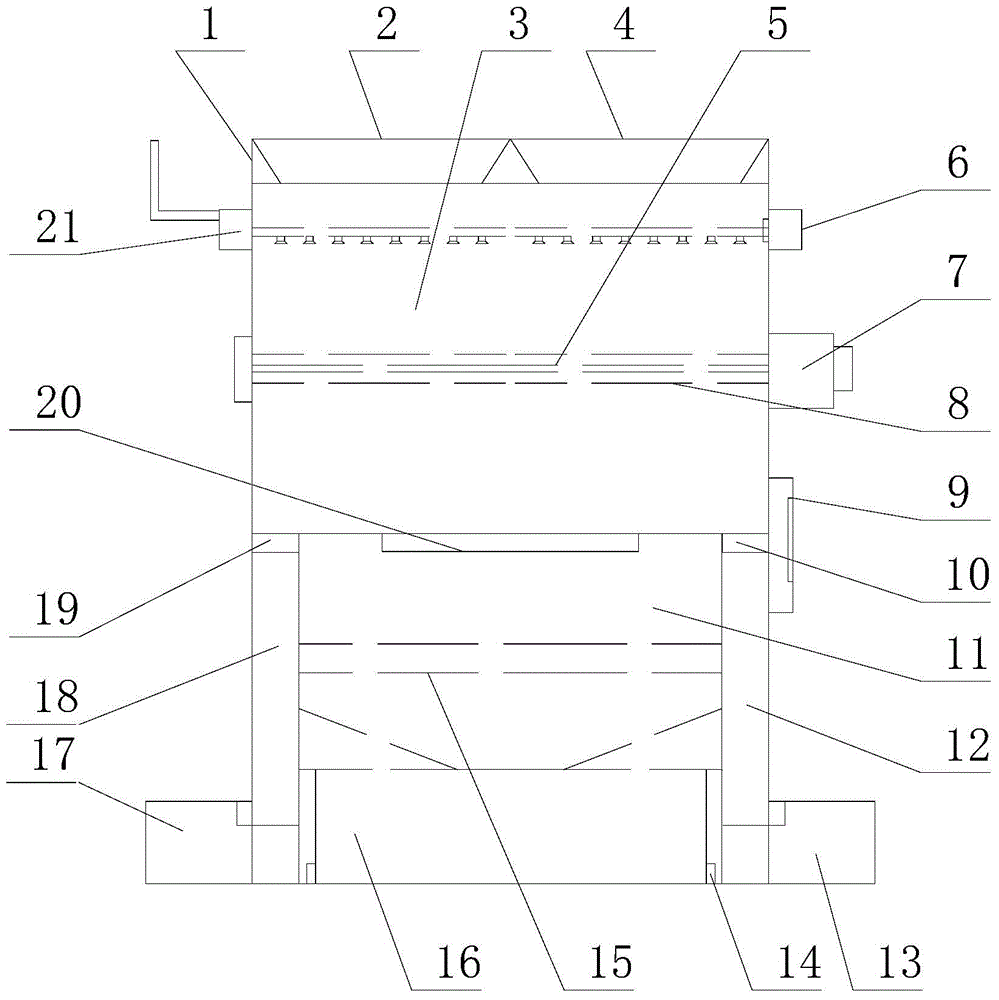

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a filter machine with a self-cleaning filter plate according to the present invention includes a barrel shell 1, and the left and right feed ports 2 and right feed ports are respectively arranged on the left and right sides of the upper surface of the barrel shell 1. The feed port 4; the barrel shell 1 is divided into an upper chamber 3, a lower chamber 11 and a feed chamber 16 from top to bottom; a horizontal bar 5 is arranged in the middle of the upper chamber 3, and A frame-shaped filter plate 8 with a filter screen is set, and a servo motor 7 is arranged on the right side of the upper chamber 3, and the shaft head of the servo motor 7 is connected with the right end of the horizontal bar 5; A pump 21 is set, and a fan 6 is set on the right side of the upper chamber 3; a horizontal water pipe is arranged on the upper part of the upper

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap