Moxa cone forming die

A technology for forming moulds, forming holes, applied in the direction of material forming presses, manufacturing tools, presses, etc., can solve the problems of poor sanitation, affecting the treatment effect, and low kneading efficiency of forming moxa pillars, and achieves convenient and fast production process , meet the standardization requirements, and the outer wall is flat and complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

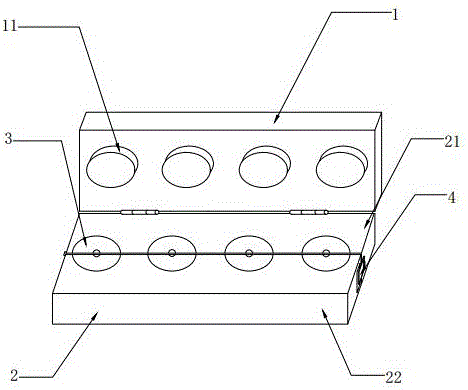

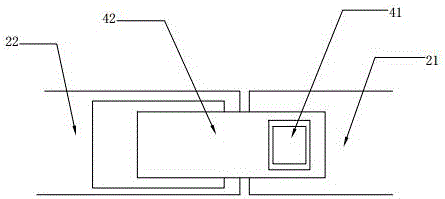

[0024] The first bottom plate 21 and the second bottom plate 22 are locked by the locking device 4, the moxa velvet is added into the forming hole groove 3, and the added amount can be flush with the groove, and then the press cover 1 is turned over to squeeze, and the The squeezing action of the forming hole groove 3 and the pressing button 11 can make the moxa velvet form. After pressing and forming, the press cover 1 is turned outward, and the unlocking and locking device 4 can separate the first bottom plate 21 and the second bottom plate 22, and the moxa column can be automatically dropped.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap