Special forming die frame for refrigeration evaporator capable of being folded in half on same plane

A refrigerated evaporator and co-planar technology, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as forming, and achieve the effects of good product quality, high production efficiency, and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

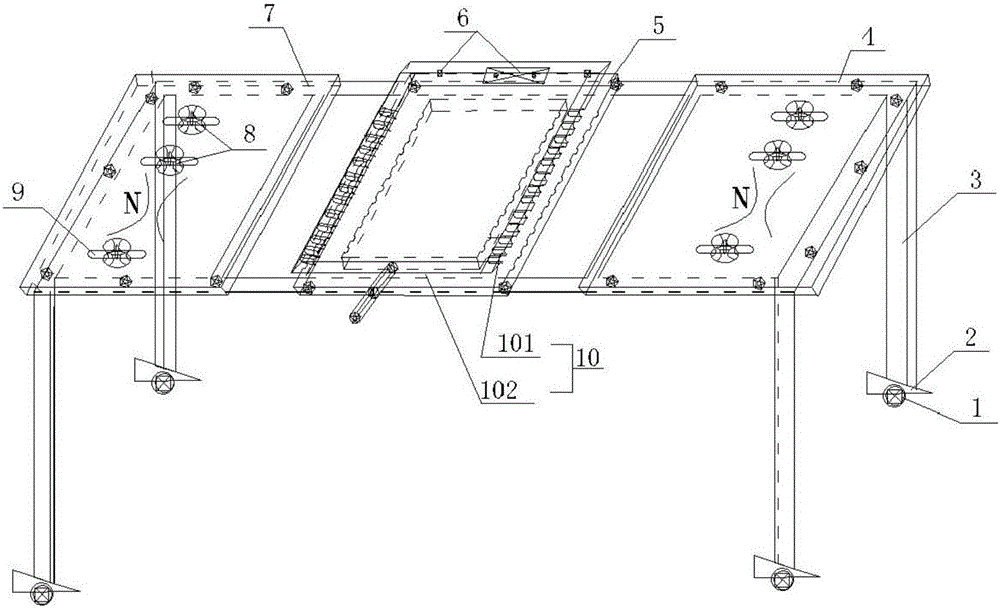

[0013] Refer to the accompanying drawings: a special forming mold frame that can be folded in half on the same plane, including movable support frames (1, 2 and 3), co-planar molds (4, 5 and 7), neutral clamping mold frames (6 and 10) and the card position orientation wheel 8, the movable support frame (1, 2 and 3) is composed of a sliding steering wheel 1, a fixed supporting plate 2 and a rectangular support frame 3, and the same plane mold (4, 5 and 7 ) includes left mold 7, right mold 4 and neutral clamping mold 5, left mold 7, right mold 4 and neutral clamping mold 5 in the same plane mold are on the same horizontal plane, left mold 7 and right mold There is a waist-shaped through hole 9 on the top of the 4, and the clamping directional wheel 8 is installed at the waist-shaped through hole 9, and the coplanar molds (4, 5 and 7) are installed on the movable support frame (1, 2 and 3), The neutral clamping mold frame (6 and 10) is interconnected with the neutral limiting clampi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap