Electric central frame for crankshaft

A center frame and crankshaft technology, applied in the field of crankshaft electric center frame, can solve the problems of poor center positioning performance of lathe fixtures, many operation steps, time-consuming and laborious, and achieve fast positioning speed, high positioning accuracy, and improve work efficiency and machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

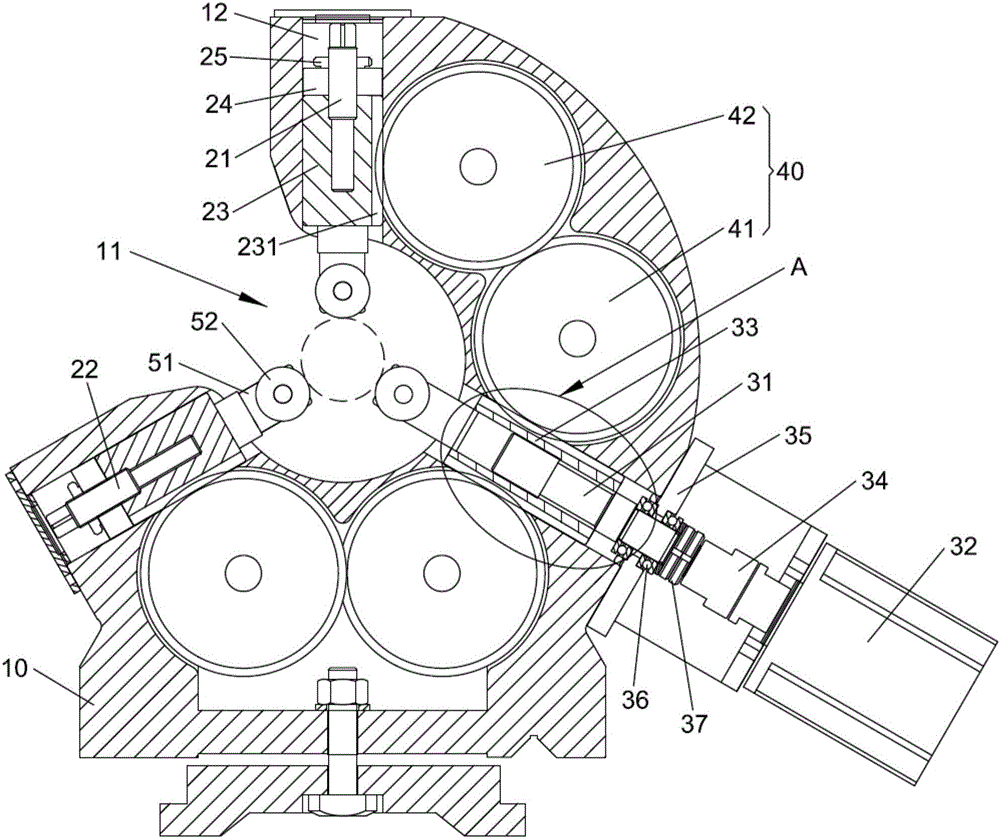

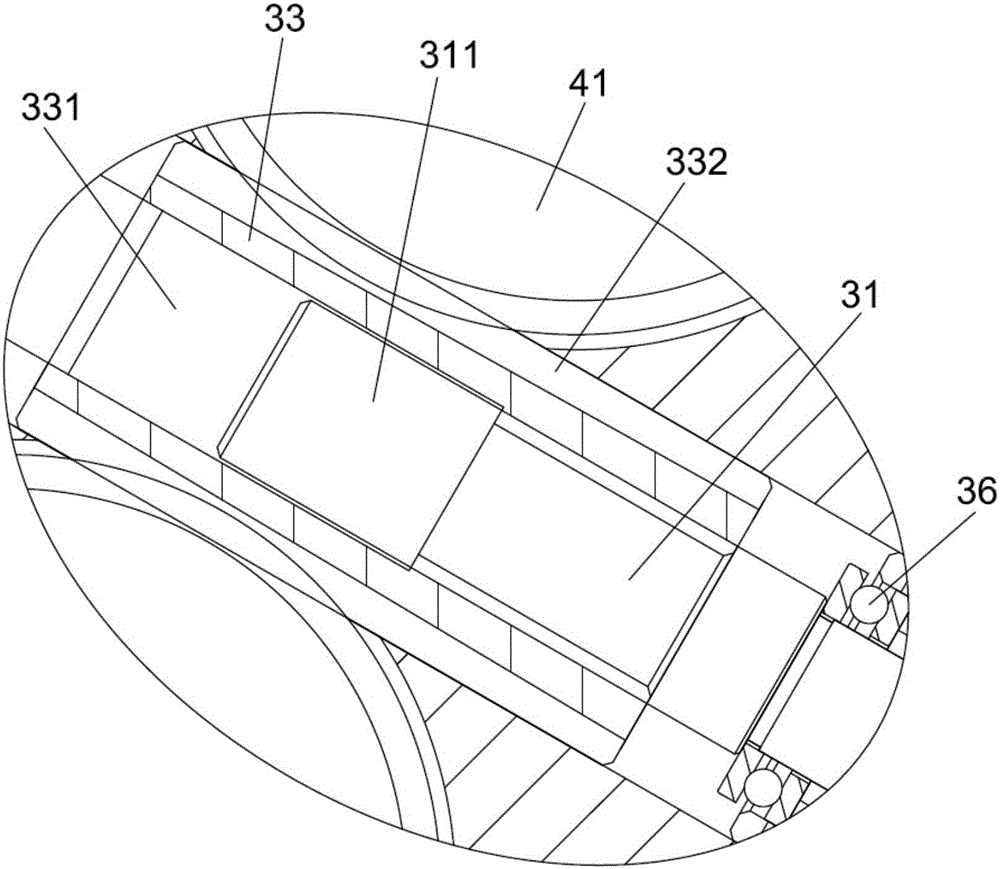

[0016] refer to figure 1 with figure 2 , the present invention provides a crankshaft electric center frame, comprising a base 10, on which a transmission shaft 1 21, a transmission shaft 2 22 and a transmission shaft 3 31 are arranged, the transmission shaft 1 21, the transmission shaft 22 and the transmission shaft 3 31 The three are mutually distributed in a 120° ring shape, so that the force is stable and the clamping is reliable. Transmission shaft one 21 is positioned at the base 10 upper end, and transmission shaft two 22 and transmission shaft three 31 are symmetrically arranged below transmission shaft one 21, and the base 10 between transmission shaft one 21 and transmission shaft two 22 is provided with for placing the crankshaft. The opening groove 11. A driven rack sleeve 23 is fixedly connected to the first transmission shaft 21 and the second transmission sha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap