Removable shunting canopy mechanism

A detachable, carport technology, applied in locomotives, motor vehicles, railway car bodies, etc., can solve problems such as unfavorable remote control operation of shunting locomotives, hidden dangers in the safety of shunting personnel, etc., and achieve the effect of convenient installation and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

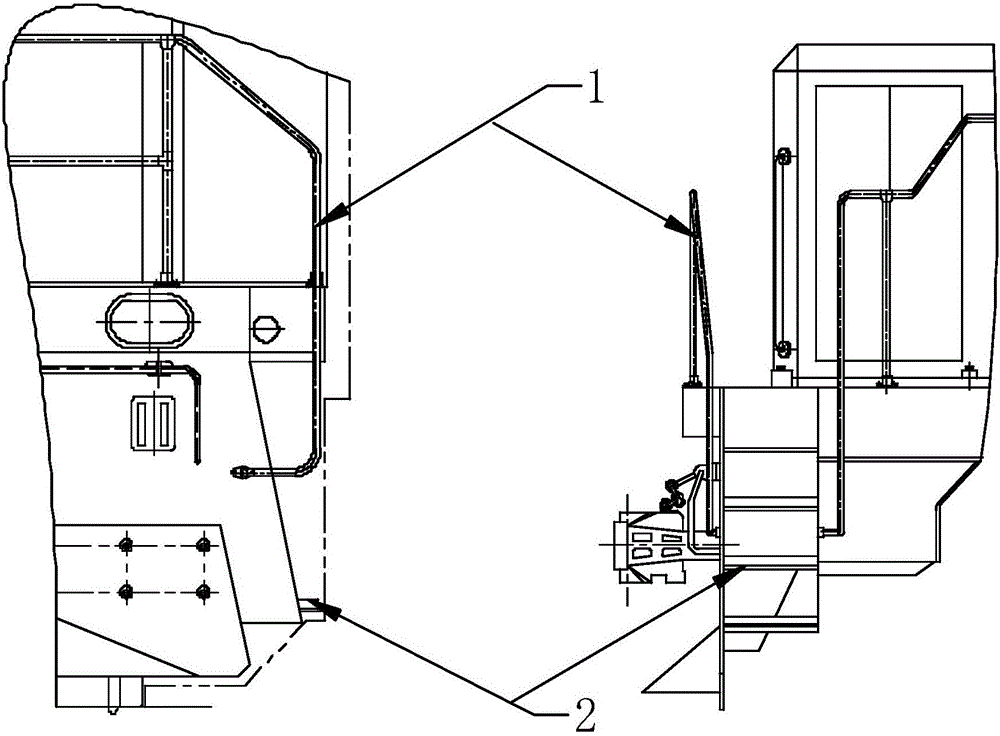

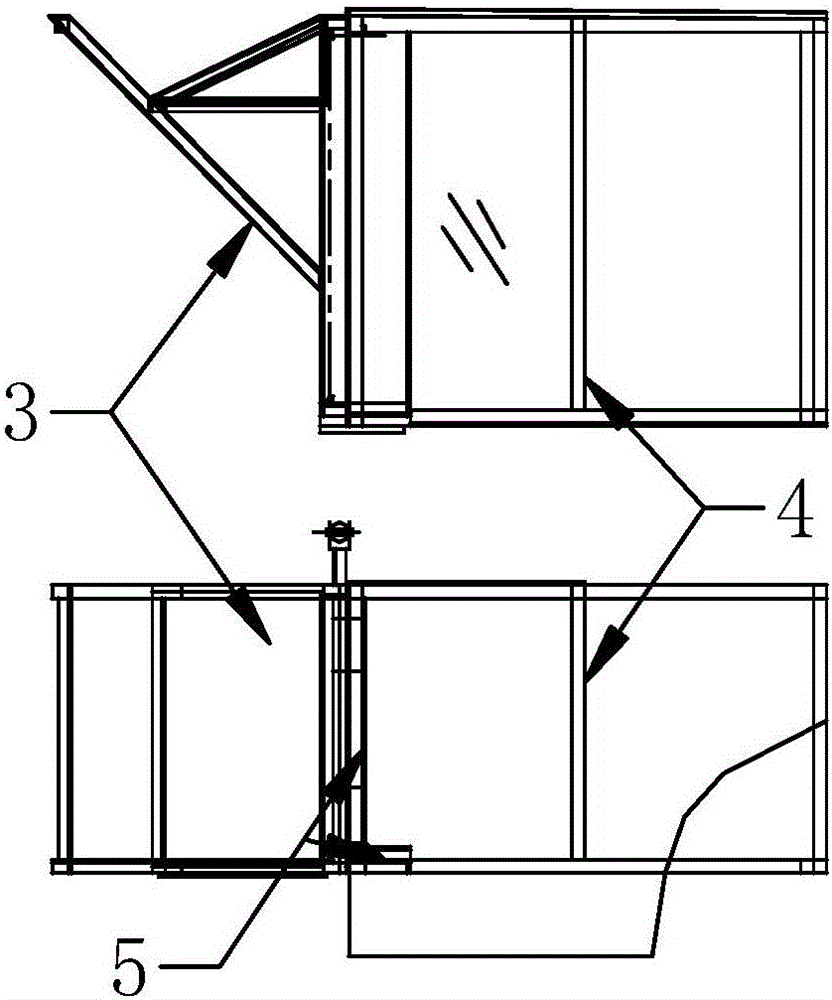

[0018] The present invention is made up of bracket assembly 3 and cover panel assembly 4, and the hinge is connected with bracket assembly 3 and cover panel assembly 4 by riveting, so that these two parts become a whole, such as figure 2 shown.

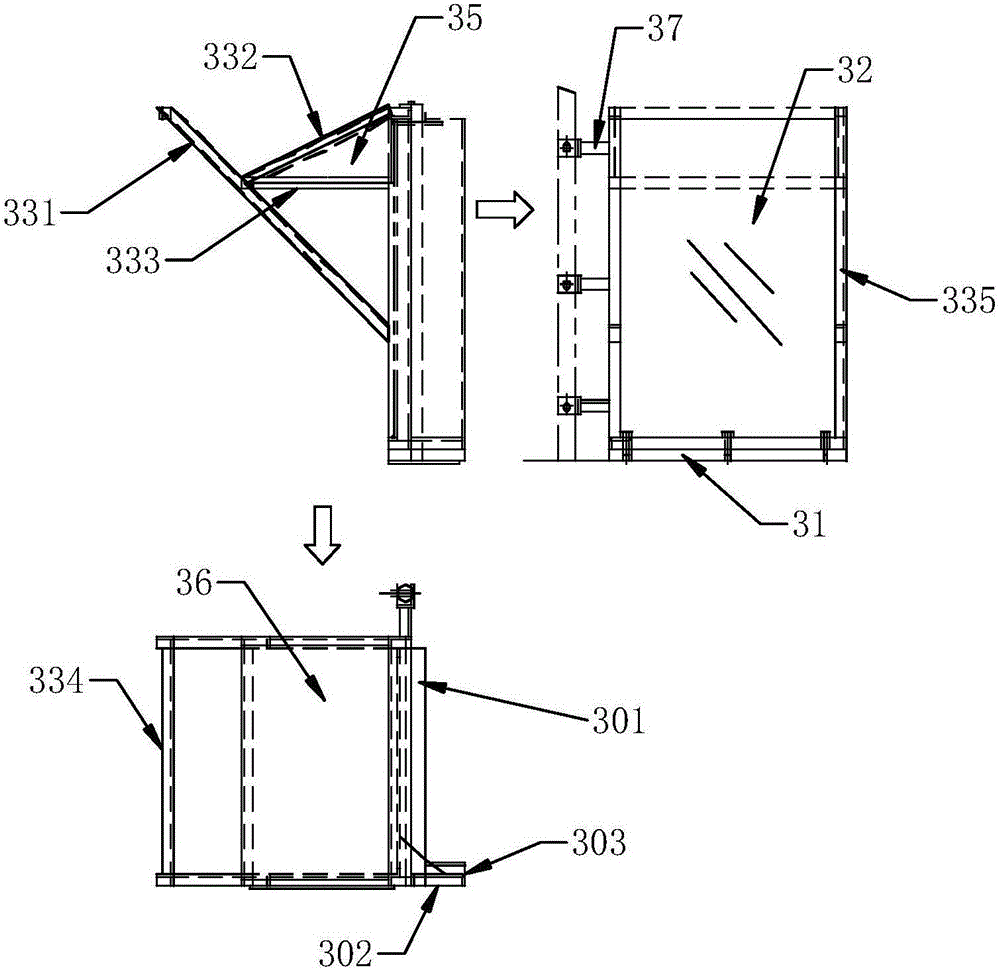

[0019] Bracket assembly 3 consists of square steel one 331, square steel two 332, square steel three 333, square steel four 334, square steel five 335, baffle one 35, baffle two 36, fixed frame 37, tempered glass 32, channel steel one 301, channel steel 2 302, channel steel 3 303, bottom plate 31 and two sets of fasteners, such as image 3 shown. First, square steel one 331, square steel two 3332, square steel three 333, square steel four 334, square steel five 335, baffle one 35, baffle two 36, fixed frame 37, channel one 301, channel two 302, channel steel three 303 are welded together by welding to form an integral frame str...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap