Preparation method of sand foundation model in sand foundation model experiment

A sandy soil foundation model and model technology, applied in the preparation of test samples, etc., can solve the problems of difficult precise control of drop distance, large error of sandy soil foundation model density, and low accuracy, so as to avoid difficult precise control, Reliable test data, good reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A kind of embodiment of the present invention is, a kind of preparation method of the sand foundation model in the sand foundation model test, and its operation steps are:

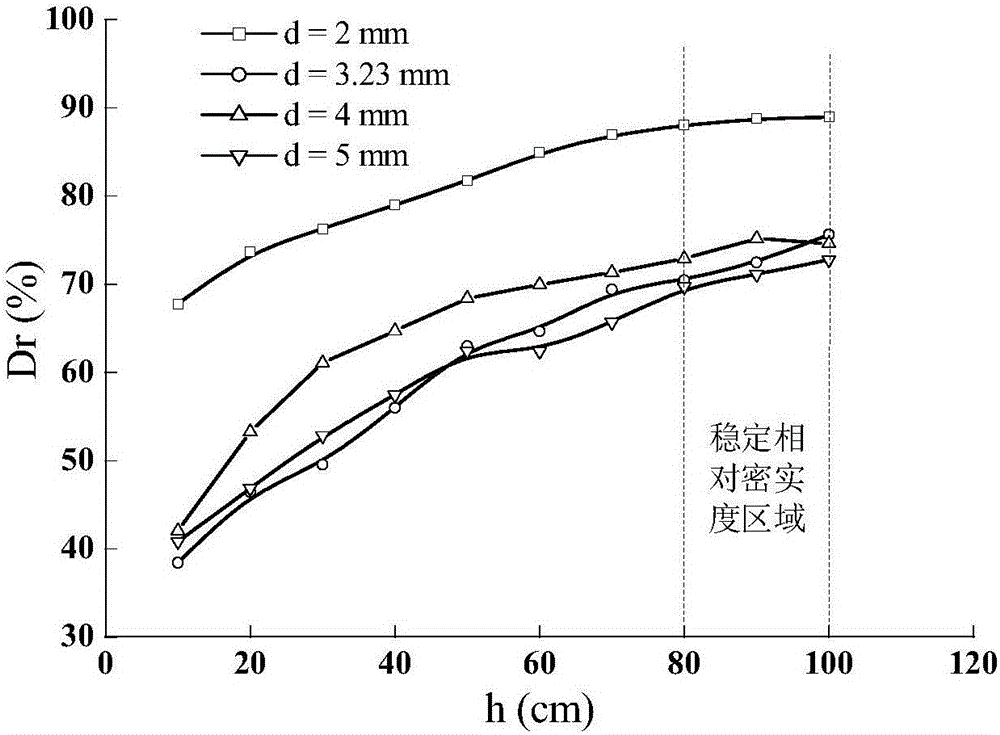

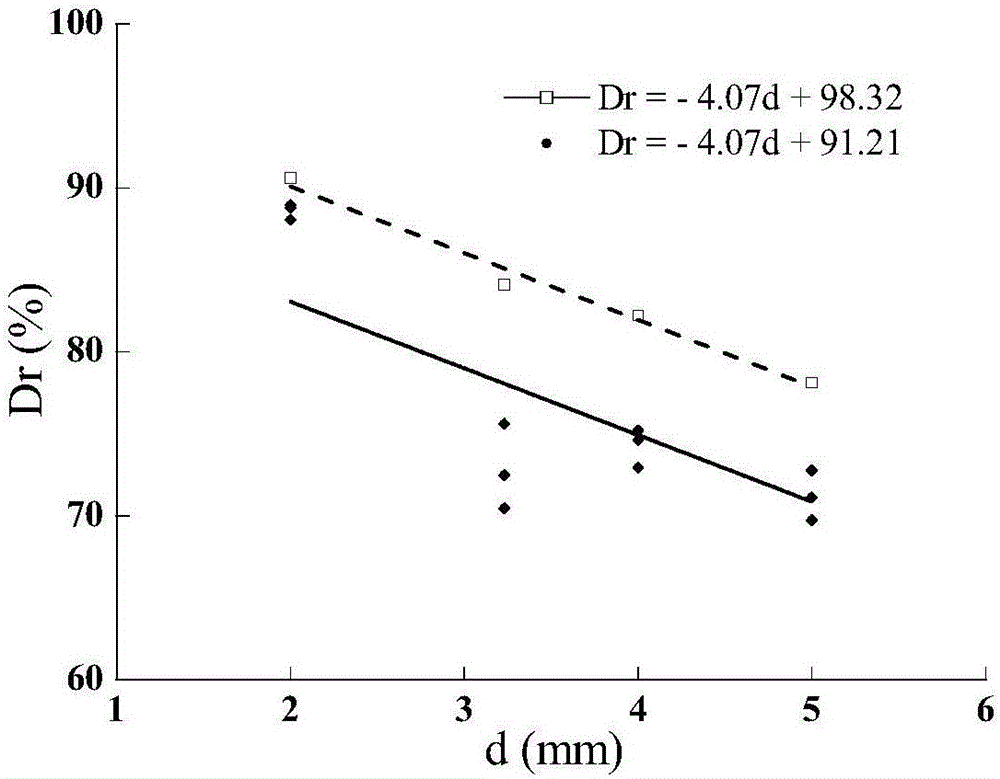

[0031] A. Determination of the diameter of the sand hole: according to the relative compactness D of the sand foundation model to be prepared r , Calculate the diameter of the sand hole d(mm) of the sand head, d=22.41-0.25D r ;

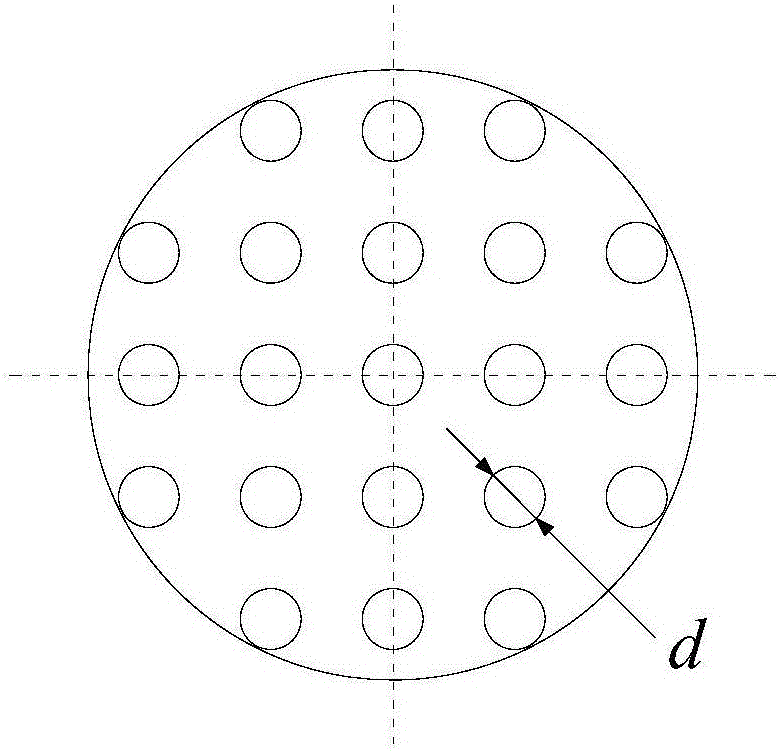

[0032] B. Opening of the sand outlet head: open a sand outlet hole with the diameter d of the sand outlet hole determined in step A at the bottom of the sand outlet head;

[0033] C. Preparation of the model: connect the top of the sand head prepared in step B to the sand barrel through a hose, and under the condition of a falling distance of 80cm to 100cm, pass through the sand hole of the sand head to the model box directly below it. Sprinkle the sand with the dripping glass until the sand sample in the model box reaches the set thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap