Holder control system of autonomous homing calibration

A technology of control system and pan/tilt, which is applied in the direction of using feedback control, etc., can solve problems such as the influence of the accuracy of the detection method of the rotary potentiometer, the increase in the complexity of the control system design, and the influence of the circuit system, so as to save labor and reduce position errors. , The effect of the simple calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

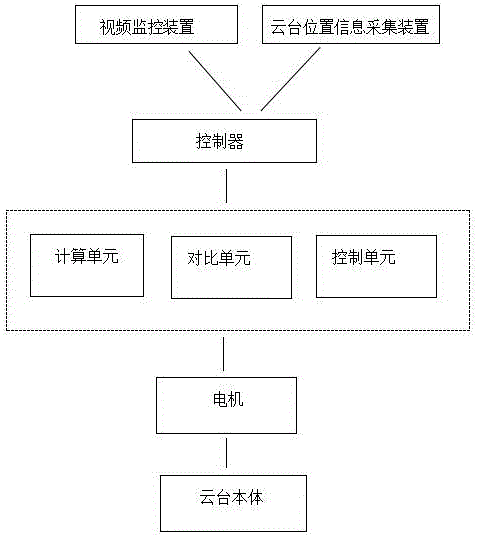

[0019] to combine figure 1 , the present invention provides a pan-tilt control system for autonomous homing calibration, comprising: a pan-tilt body, which includes a box body, a support frame, a cavity environment information collection module, a communication module and a pan-tilt state information collection module, and the box is set A video monitoring device and a lighting device are arranged, and the video monitoring device collects the position information of the cloud platform body, the video monitoring device is a high-definition camera, the support frame is a rotatable support frame, and the lighting device is an LED lamp; a brushless stepping motor, which includes The transmission main shaft, the motor is connected with the pan-tilt body to control the rotation of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap