Handrail welding worktable of ventilation port cover for spraying workshop

A vent cover and workbench technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as railing falling off, railing and vent cover frame loosening, etc., to achieve convenient welding and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

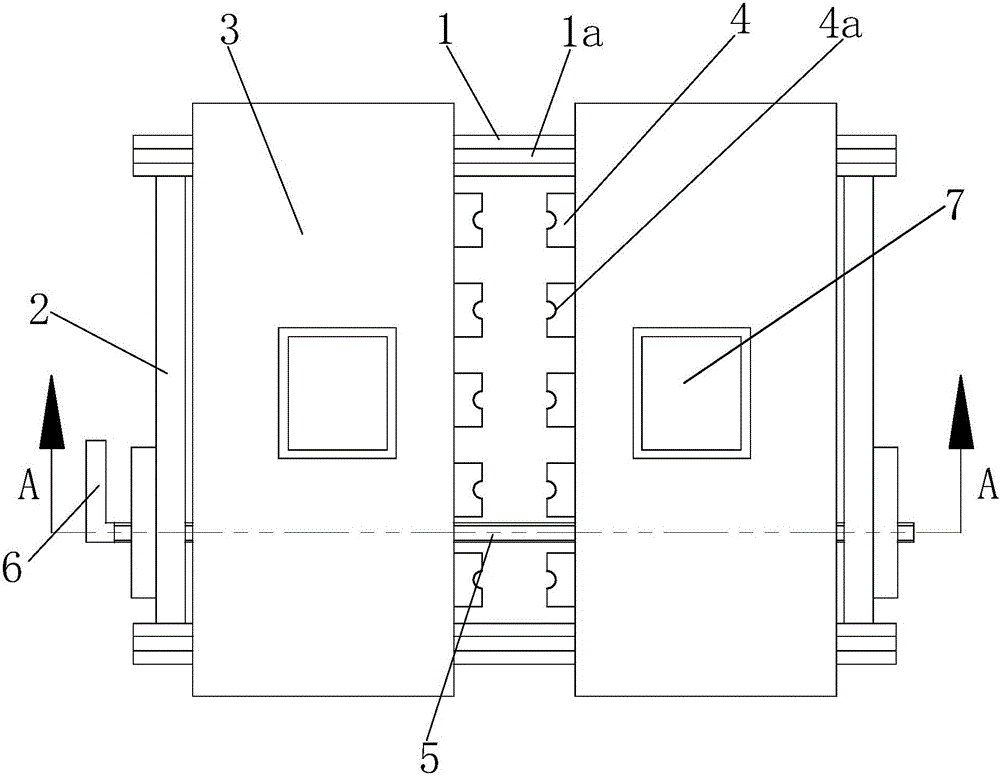

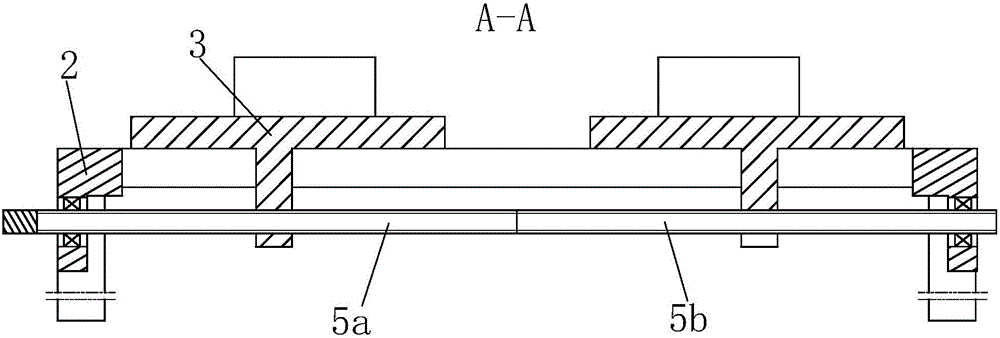

[0015] Such as Figure 1 to Figure 2 As shown, a railing welding workbench for a vent cover in a spraying workshop includes a horizontal back frame 1 and a longitudinal leg frame 2 welded to each other, the horizontal back frame 1 is provided with a chute 1a, and the upper end of the chute 1a Two table tops 3 are slidably installed, and each table top 3 is arranged with blocks 4 along the front and back direction on the side close to the center of the horizontal retreat frame 1, and each block 4 is provided with a semicircular card slot 4a . The blocks 4 on the two table tops 3 are symmetrically distributed.

[0016] A long screw 5 is installed on the longitudinal leg frame 2 through a bearing, and the long screw is welded by a left screw 5a and a right screw 5b with opposite helical dir

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap