High-purity VCR metal surface hard sealing connecting pipe

A metal-faced, hard-sealed technology, applied in the direction of pipes/pipe joints/fittings, non-detachable pipe connections, pass-through components, etc., to achieve the effect of easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

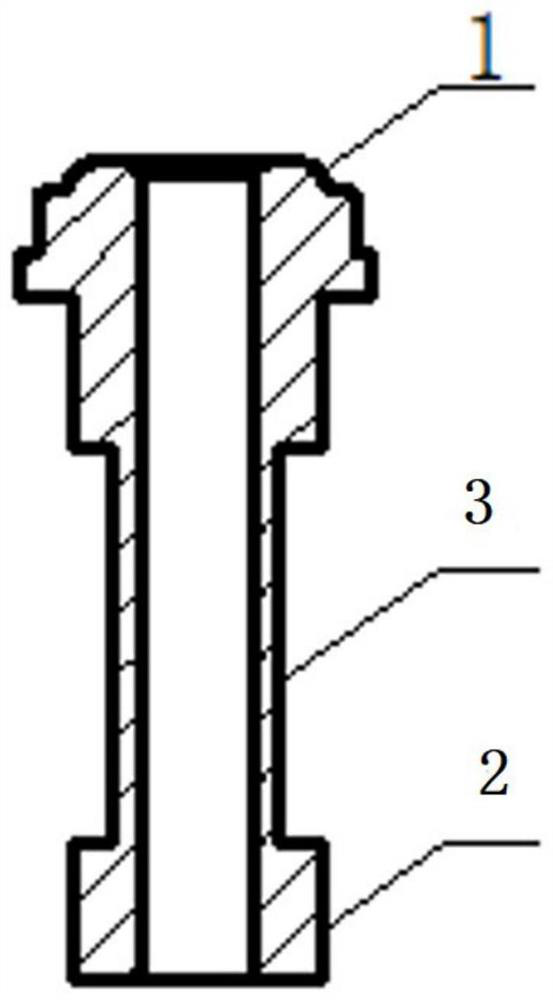

[0025] See figure 1 A high-purity VCR metal face hard sealing tube, including a high-purity VCR metal surface sealing portion 1, a normal pipe 3 in contact with the VCR metal surface sealing portion 1, and connects the normal pipe 3 and other components directly welded to the pipe 2 2 The normal pipe is consistent with the wall thickness of the reinforcing tube, and the wall thickness of the reinforcing pipe 2 is greater than the wall thickness of the normal pipe 3.

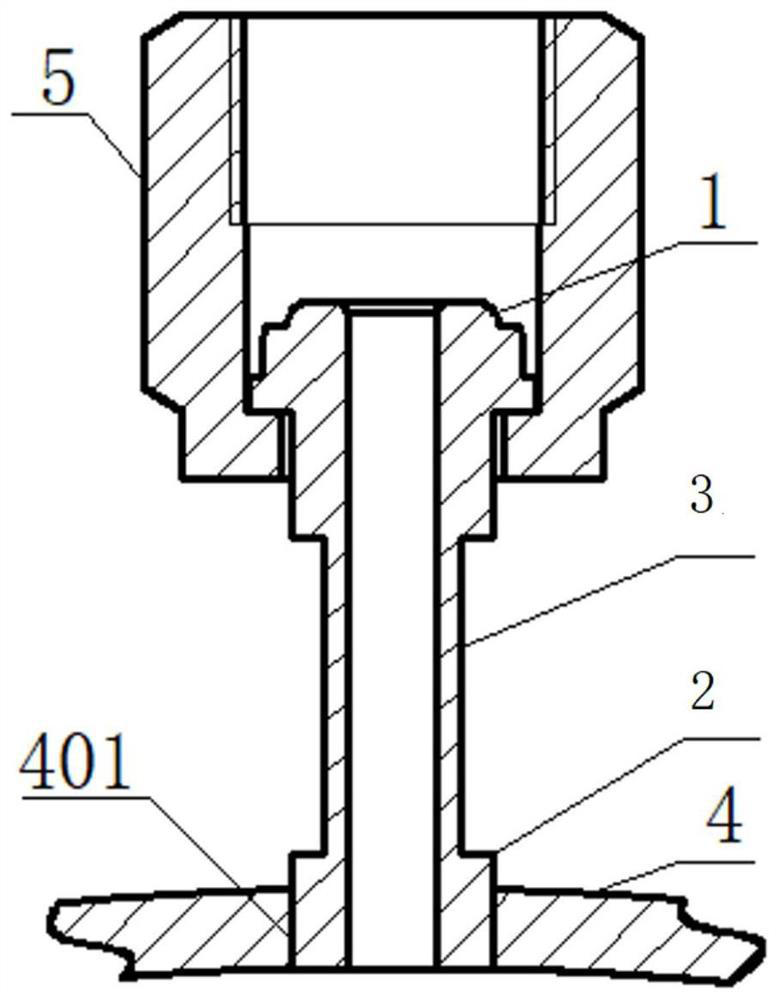

[0026] See figure 2 The connecting holes 401 for mounting the high purity VCR metal face hard sealing tube are made in the required welding member 4, and the high-purity VCR metal surface sealing portion 1 is assembled with the thread 5, and the reinforcing pipe 2 is in connection hole 401. In the middle, and one end is parallel to the bottom surface of the welded member, the reinforcing pipe segment 2 and the connecting hole 401 are fixedly connected by welding. The reinforcing tube segment 2 wall th

Example Embodiment

[0027] Example 2

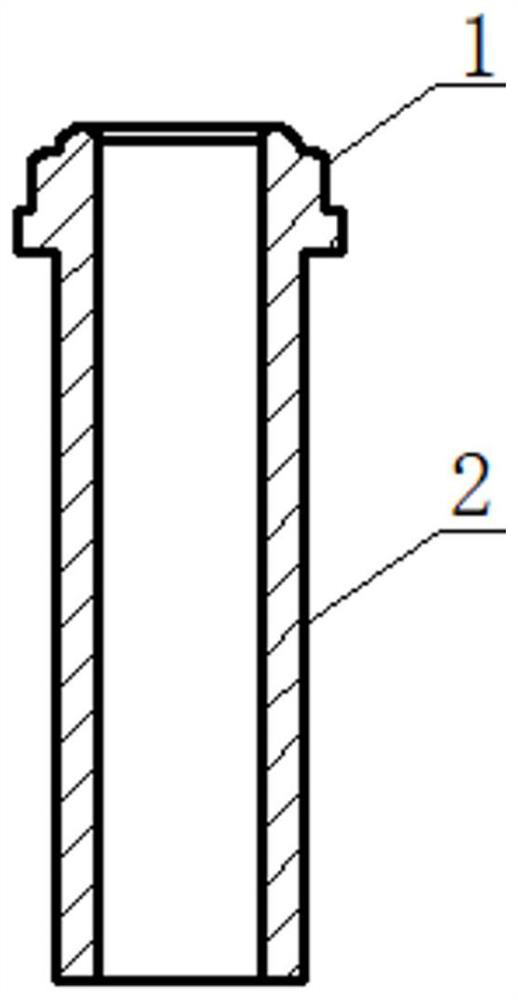

[0028] See image 3 A high-purity VCR metal face hard seal, including a high-purity VCR metal surface sealing portion 1, a reinforcing tube 2 that is connected to a high pure VCR metal surface sealing portion 1.

[0029] See Figure 4 The connection hole 401 for mounting the high purity VCR metal face hard sealing tube is made in the required welding member 4, and the reinforcing tube 2 is assembled to the thread 5, and the reinforcing pipe 2 is in the connecting hole 401, and one end is The bottom surface of the welded member is flat, and the reinforcing tube segment 2 is fixed to the connecting hole 401 by a welding. The reinforcing pipe section 2 wall thickness is not less than 1.75 mm, and the reinforcing pipe length should not be less than the thickness of the welding member.

Example Embodiment

[0030] Example 3

[0031] See figure 1 and Figure 5 , The reinforcing tube 2 port of the required welding member 4 and the high pure VCR metal face hard-sealed tube is fixed, and the reinforcing tube 2 and the welded member 4 are fixed by welding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap