Additive manufacturing formation cylinder lifting system, formation cylinder and additive manufacturing equipment

A technology of additive manufacturing and lifting system, which is applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problems of increased forming height and limited forming height, and achieve the effect of increasing forming height and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

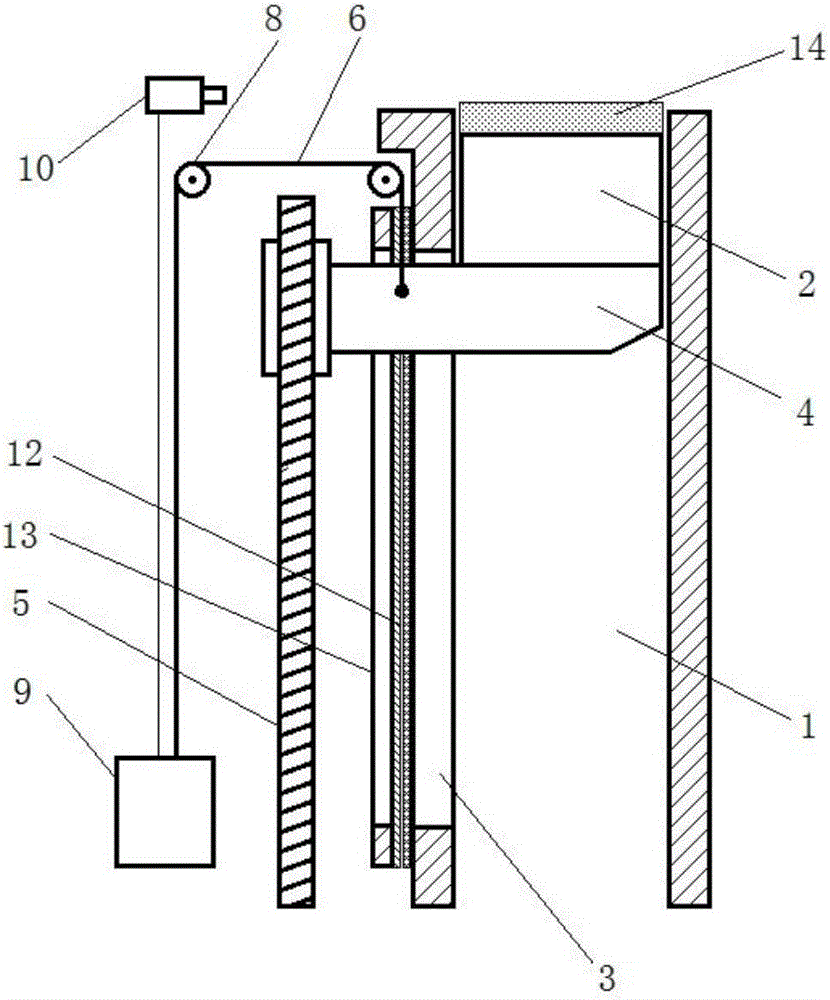

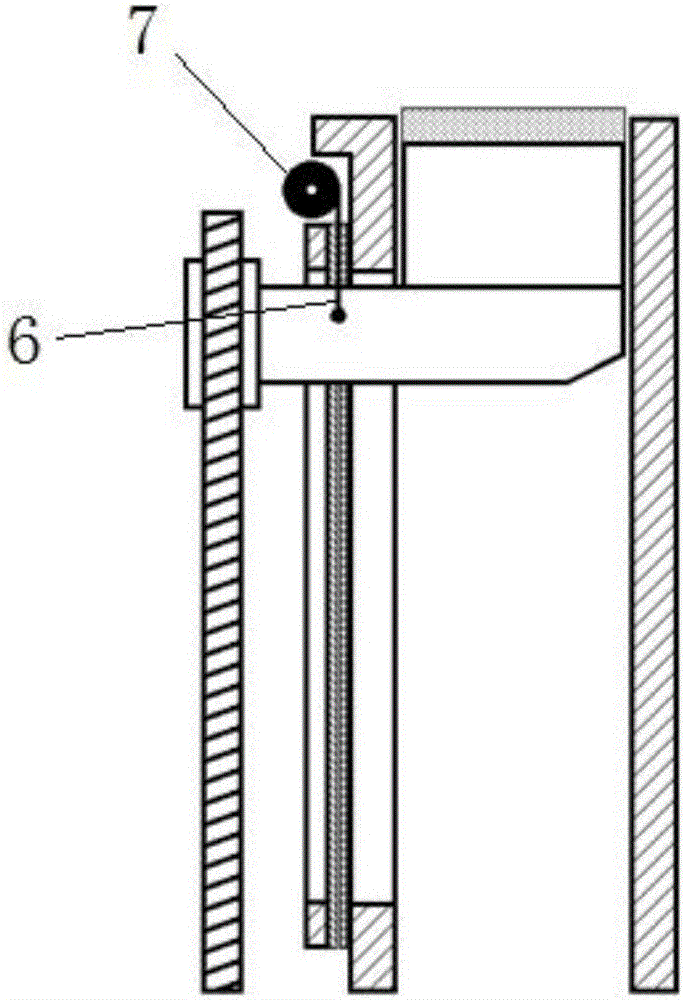

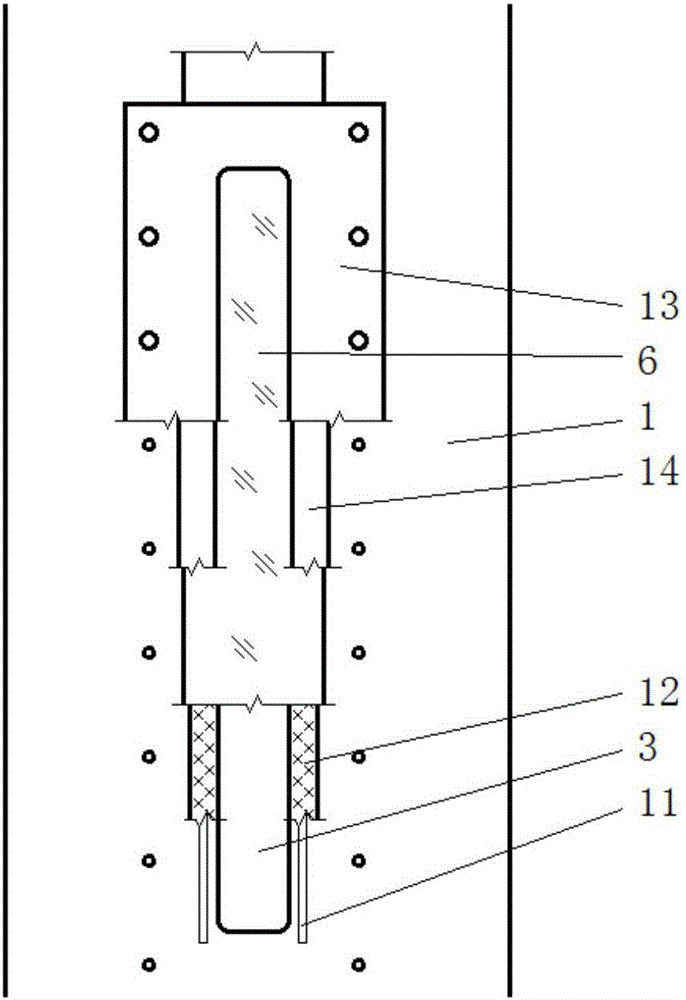

[0022] The lifting system of the forming cylinder for additive manufacturing of the present invention includes a cantilever 4 and a cantilever driving mechanism 5 , one end of the cantilever 4 is installed on the cantilever driving mechanism 5 , and the other end is a free end for fixing the substrate 2 . The cantilever drive mechanism 5 adopts a lead screw drive mechanism, which is used to drive the cantilever 4 to feed up and down, and then drives the substrate 2 to lift, such as figure 1 shown.

[0023] A longitudinal opening 3 is provided on the side wall of the additive manufacturing forming cylinder 1 with the above-mentioned lifting system, such as figure 1 As shown, the lead screw drive mechanism 5 is located outside the forming chamber, one end of the cantilever 4 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap