Heat pump system

A heat pump system and heat exchanger technology, applied in lighting and heating equipment, compressors with reversible cycles, refrigerators, etc., can solve the problems of increasing the workload of staff, too many pipelines, etc., and achieve good heating effect, Reduced workload and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

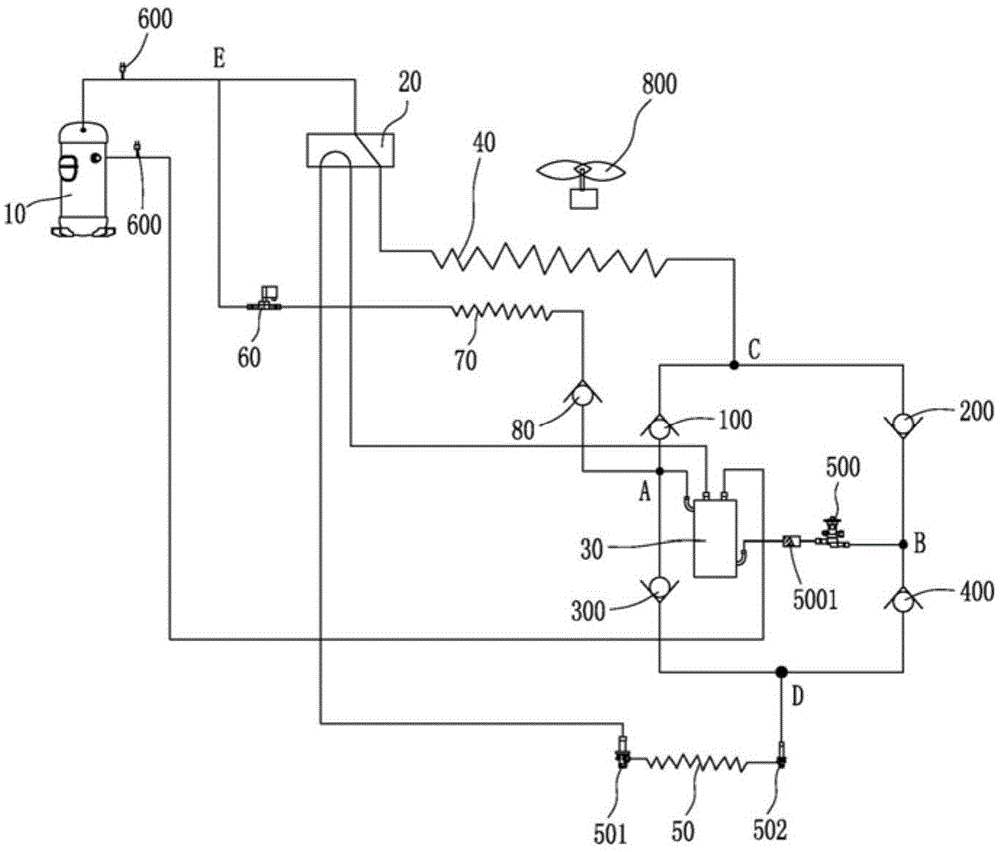

[0026] refer to Figure 1 to Figure 4 As shown, the present invention discloses a heat pump system. Specifically, we describe the structure of a heat pump system in detail. The heat pump system includes:

[0027] A compressor 10, the compressor 10 has a suction port and a discharge port;

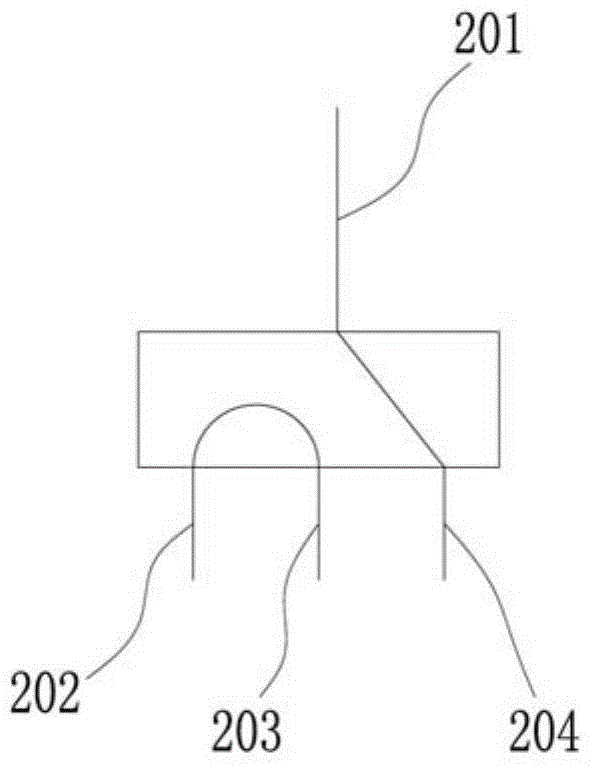

[0028] Four-way reversing valve 20, combined with figure 2 , the four-way reversing valve 20 has an exhaust port 201, a third heat exchanger port 202, an economizer port 203, and a first heat exchanger port 204;

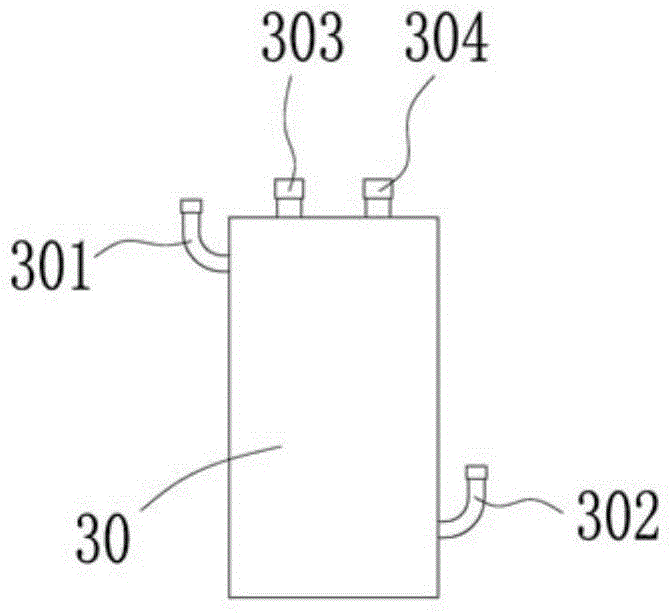

[0029] Economizer 30, combined with image 3 , the economizer has a check valve interface 301, a t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap